Current enhanced type lateral insulated gate bipolar transistor

A bipolar transistor and current enhancement technology, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of increasing device off time, decreasing latch-up suppression ability, and withstand voltage drop, so as to improve the on-current density , Improving the latch-up suppression ability and the effect of improving the conduction current capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

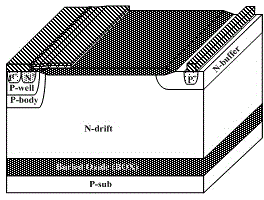

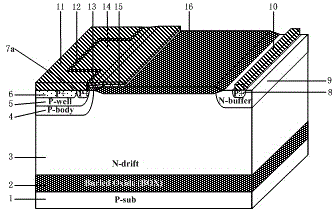

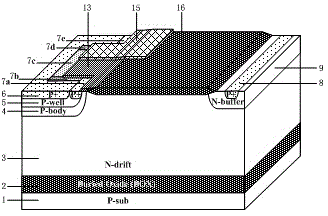

[0030] Combine below figure 2 , image 3 , to describe the present invention in detail, a current-enhanced lateral insulated gate bipolar transistor, comprising: a P-type substrate 1, a buried oxygen 2 is provided on the P-type substrate 1, and an N-type substrate is provided on the buried oxygen 2. In the drift region 3, a P-type body region 4 and an N-type buffer region 9 are respectively arranged on both sides of the N-type drift region 3, and a heavily doped P-type collector region 8 is arranged in the N-type buffer region 9. The mixed P-type collector region 8 is connected with an anode metal 10, and a field oxygen layer 16 is arranged above the N-type drift region 3. One side boundary of the field oxygen layer 16 falls above the N-type buffer zone 9, and the other One side boundary is in contact with the P-type body region 4 and is a straight boundary, a P-type well region 5 is arranged in the P-type body region 4, and a heavily doped P-type emitter region 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com