Electrode of electrochemical energy storage device and preparation method thereof

An electrochemical and electrode technology, applied in the field of electrochemical energy storage devices, to achieve the effect of increasing safety, improving safety performance and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

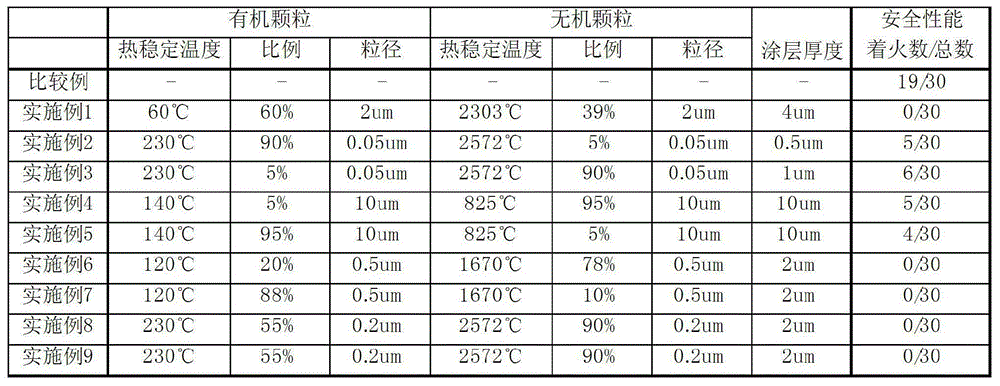

Embodiment 1

[0031] Positive sheet preparation: same as comparative example;

[0032] Functional layer slurry configuration: select beeswax particles with a particle size of 2 μm and alumina particles with a particle size of 2 μm, then add CMC (the mass ratio of the above three components is 60:39:1), and use water as a solvent. Fully stir to obtain the slurry for use;

[0033] Preparation of functional positive electrode sheet: coating the above-mentioned functional layer slurry on the surface of the above-mentioned positive electrode sheet, and drying to obtain a functional positive electrode sheet with a functional coating layer thickness of 4 μm for use;

[0034] Negative electrode sheet preparation: the same as the comparative example.

[0035] Cell assembly: Assemble the functional positive electrode, negative electrode, and separator into a bare cell, and then prepare the finished cell.

Embodiment 2

[0037] The difference from Embodiment 1 is that this embodiment includes the following steps:

[0038] Functional layer slurry configuration: select polyvinyl alcohol particles with a particle size of 0.05 μm, calcium oxide particles with a particle size of 0.05 μm, and then add CMC (the mass ratio of the above three components is 90:5:5), and water As a solvent, fully stir to obtain a slurry for use;

[0039] Preparation of functional positive electrode sheet: coating the above-mentioned functional layer slurry on the surface of the above-mentioned positive electrode sheet, and drying to obtain a functional positive electrode sheet with a functional coating layer thickness of 0.5 μm for use;

[0040] The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0042] The difference from Embodiment 1 is that this embodiment includes the following steps:

[0043] Functional layer slurry configuration: select polyvinyl alcohol particles with a particle size of 0.05 μm and calcium oxide particles with a particle size of 0.05 μm, then add CMC (the mass ratio of the above three components is 5:90:5), and mix with water As a solvent, fully stir to obtain a slurry for use;

[0044] Preparation of functional positive electrode sheet: coating the above-mentioned functional layer slurry on the surface of the above-mentioned positive electrode sheet, and drying to obtain a functional positive electrode sheet with a functional coating layer thickness of 1 μm for use;

[0045] The rest are the same as in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com