Antistatic polytetrafluoroethylene filter bag

A technology of polytetrafluoroethylene and filter bags, which is applied in the direction of dispersed particle filtration, layered products, metal layered products, etc., can solve the problems of poor anti-static, achieve static elimination, long-lasting anti-static properties, and good electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further elaborated in conjunction with the accompanying drawings.

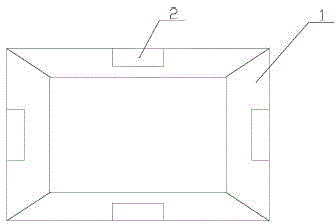

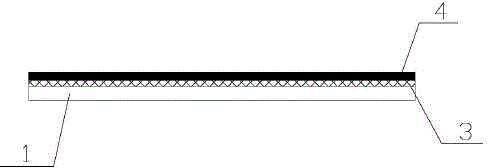

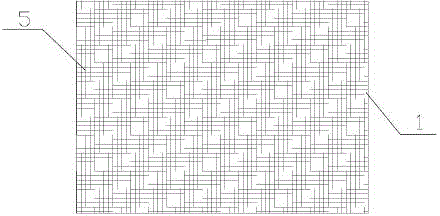

[0013] Such as figure 1 As shown, an antistatic polytetrafluoroethylene (PTFE) filter bag: the filter bag includes a bag head 1, a bag body 2 and a bag bottom 3, and the bag head 1, bag body 2 and bag bottom 3 are all made of polytetrafluoroethylene (PTFE) Made of tetrafluoroethylene filter material. figure 2 It is a structural schematic diagram of polytetrafluoroethylene filter material in the present invention, and this polytetrafluoroethylene filter material comprises base cloth 11, and this base cloth 11 is made of polytetrafluoroethylene filament fiber and stainless steel fiber twisting and plying, through warp, weft woven together, image 3 It is a schematic diagram of the network structure of the base cloth in the present invention. The upper and lower sides of the base cloth 11 are symmetrically covered with a non-woven layer 12; the non-woven layer 12 is polytetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com