A Flotation Clean Coal Recovery Uniform Mixing Process

A flotation and clean coal technology, applied in the direction of solid separation, etc., can solve the problems of dehydration effect and clean coal filter press, etc., and achieve the effect of reducing ash content, enhancing the degree of dispersion, and enhancing the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

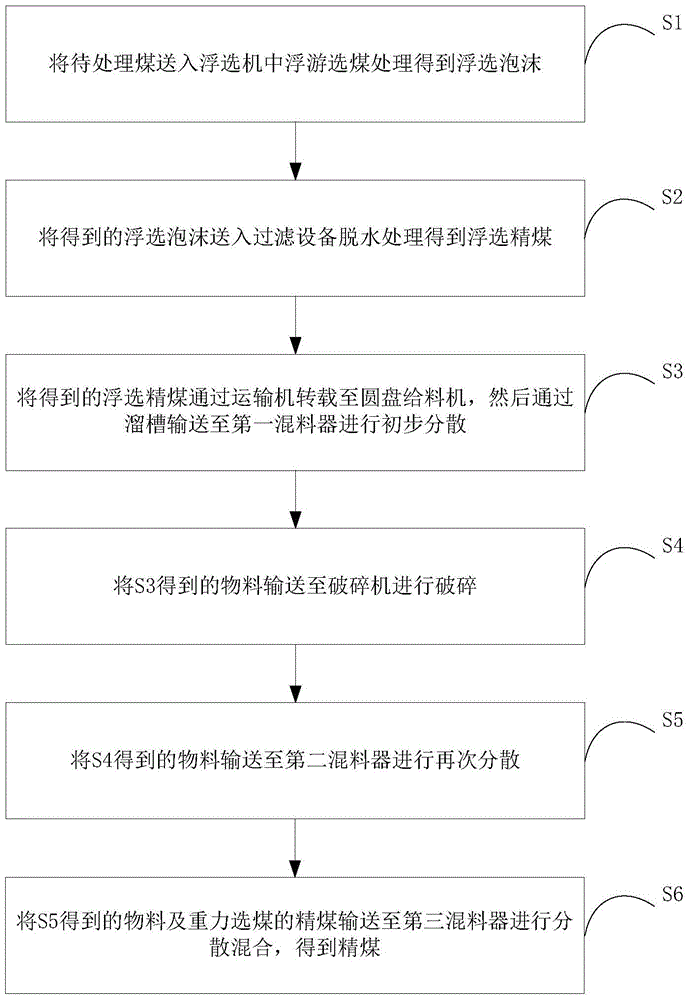

[0036] refer to figure 1 , a flotation clean coal recovery uniform mixing process, comprising the steps of:

[0037] S1, sending the coal to be processed into the flotation machine for flotation coal preparation to obtain flotation foam;

[0038] S2, sending the obtained flotation foam into the filter equipment for dehydration treatment to obtain flotation clean coal;

[0039] S3, transfer the obtained flotation clean coal to the disc feeder through the conveyor, and then transport it to the first mixer through the chute for preliminary dispersion;

[0040] S4, transporting the material obtained in S3 to the crusher for crushing;

[0041] S5, transporting the material obtained in S4 to the second mixer for re-dispersion;

[0042] S6. Transport the material obtained in S5 and the clean coal of gravity coal separation to the third mixer for dispersion and mixing to obtain clean coal.

Embodiment 2

[0044] A flotation clean coal recovery uniform mixing process, in S2, the flotation foam is sent to a clean coal filter press and / or pressure filter for dehydration treatment, to obtain flotation clean coal.

[0045] Other steps are with embodiment 1.

Embodiment 3

[0047] A flotation clean coal recovery uniform mixing process, in S2, 30wt% flotation foam is sent to the clean coal filter press for dehydration treatment, to obtain the first filter cake and the first filtrate, the water content of the first filter cake is 24.5 %, the solid content of the first filtrate is 0.011g / L, and the 70wt% flotation foam is sent into the pressure filter for dehydration treatment to obtain the second filter cake and the second filtrate, and the water content of the second filter cake is 19.3%. The solid content of the second filtrate is 6.5g / L, and the first filter cake and the second filter cake are combined to obtain flotation clean coal. The first filtrate is sent to the circulating water tank for recycling as circulating water, and the second filtrate is sent to the thickener by the coal slime water system. deal with.

[0048] Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com