Zero-pollution glue-free bamboo and/or wooden recombined material and manufacturing method thereof

A production method, bamboo technology, applied in wood compression, manufacturing tools, wood treatment, etc., can solve the problems of production process pollution, weak bamboo industrial processing technology, adhesive pollution and public hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0193] The specific manufacturing steps of recombinant materials include:

[0194] (1) Preparation of bamboo unit:

[0195] The original bamboo with a bamboo age of 4 years is used as a raw material. After the original bamboo is processed into a fixed section, the original bamboo is processed into rectangular bamboo slices through longitudinal disentanglement. The size is preferably: thickness is 6mm, width is 25mm, and longitudinal length is 1.2m.

[0196] (2) softening treatment:

[0197] Soften the bamboo unit made in step 1. Cook in hot water at a temperature of 100°C for 2 hours.

[0198] (3) Moisture content control:

[0199] The bamboo unit is placed in a drying kiln at 50° C. for drying treatment, and the moisture content is controlled at 40%.

[0200] (4) Forming group blank:

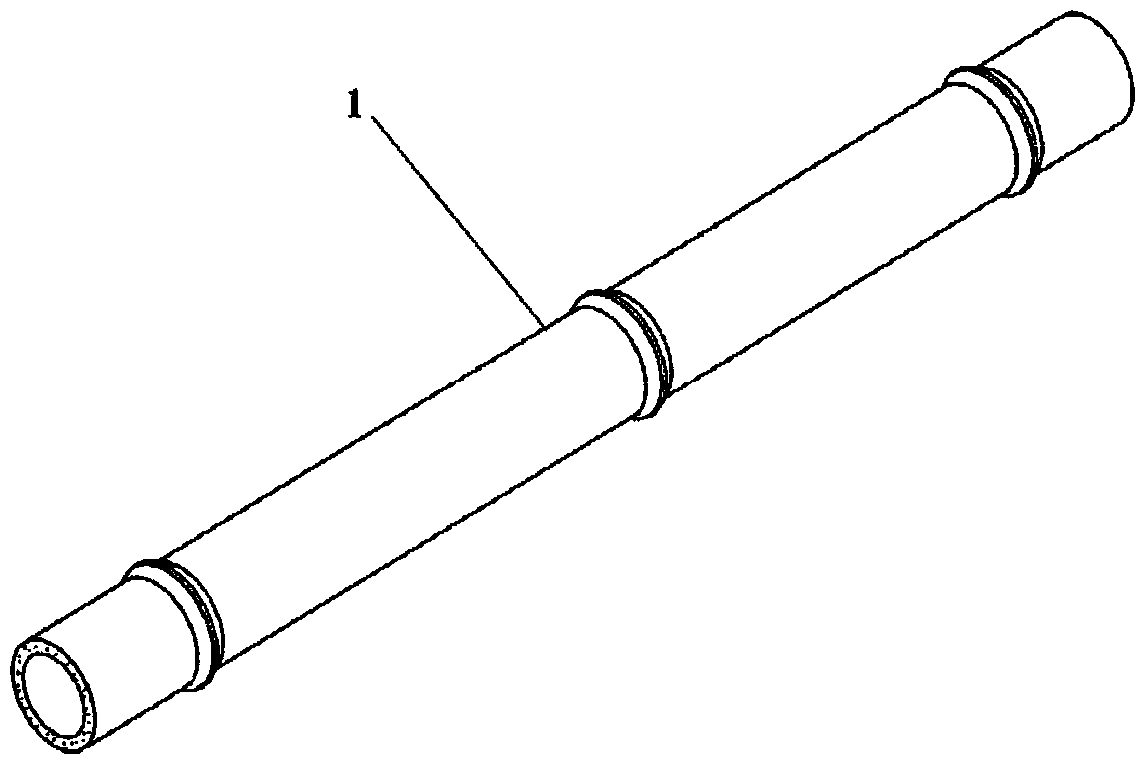

[0201] The dried bamboo unit is formed into a rectangular shape as required, and the specific form of the blank can be as follows: Figure 10 shown.

[0202] (5) Densification treatment:...

Embodiment 2

[0211] In the present embodiment, (1) the preparation of bamboo unit:

[0212] Be that the original bamboo of 4 years is processed into the definite section with the bamboo age and go green arc-shaped bamboo chip 7 (see Figure 9 ), the size is preferably: the thickness is 6mm, the width is 25mm, and the longitudinal length is 1.2m. The curved bamboo slices are neatly arranged according to the direction of the arc (such as Figure 14 shown).

[0213] Other steps are with embodiment 1.

Embodiment 3

[0215] In the present embodiment, (1) the preparation of bamboo unit:

[0216] Be that the original bamboo of 4 years is processed into fixed section with bamboo age and do not go green rectangular bamboo slice after processing, and thickness is 6mm, and width is 30mm, and longitudinal length 1.2m.

[0217] Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com