Treatment method for complex metal wastewater

A technology for complex metal wastewater and a treatment method, which is applied in the field of complex metal wastewater treatment, can solve the problems of biochemical system influence, poor biodegradability, and excessive hardness, and achieves the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Sewage is selected from a sewage plant electroplating wastewater physicochemical precipitation effluent. The heavy metal in the water quality is mainly complex copper. The indicators of the water plant are as follows: COD 476.87mg / L, copper 6.42mg / L, ammonia nitrogen 57.32mg / L.

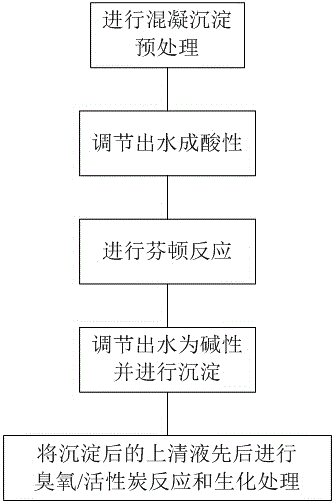

[0034] Such as figure 1 As shown, the process of treating the electroplating wastewater physical and chemical precipitation effluent is as follows:

[0035] 1. Adjust the pH value of the precipitated water after coagulation and sedimentation pretreatment to 2.5, add ferrous sulfate heptahydrate to 3.055g / L, and add 30% hydrogen peroxide to 1.94ml / L for Fenton Reaction (Fenton), the reaction time is 120 minutes, and the measured COD in the water is 195mg / L, copper 0.26mg / L, ammonia nitrogen 78.54mg / L, in which ferrous sulfate heptahydrate is used as a catalyst, and hydrogen peroxide is used as an oxidant to make Fast and efficient Fenton reaction;

[0036] 2. Adjust the pH of the effluent to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com