Unsaturated polyester resin used for bulk molding compound and preparation method thereof

A technology of bulk molding compound and polyester resin, applied in the chemical industry, can solve the problems of high cost, limited industrial application, insufficient mechanical properties, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

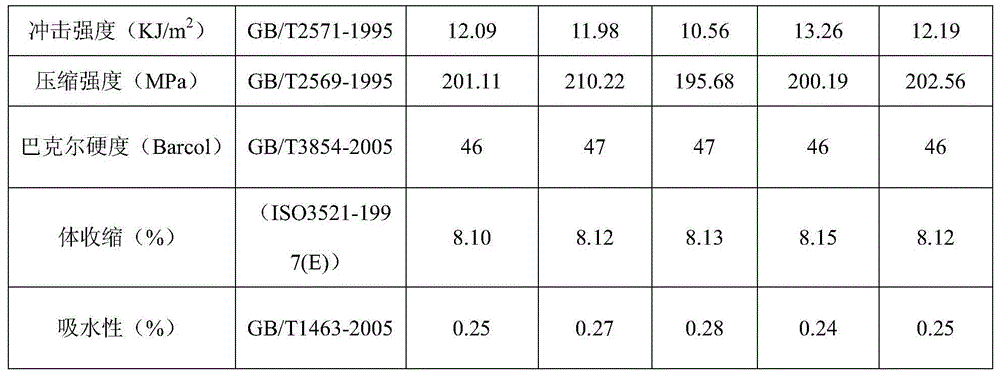

Examples

Embodiment 1

[0024] Formula: 2000 parts by weight of phthalic anhydride, 7500 parts by weight of maleic anhydride, 3700 parts by weight of diethylene glycol, 4500 parts by weight of 1,2-propanediol, 3 parts by weight of triphenyl phosphite, 8 parts by weight of hydroquinone, methyl hydrogen 7 parts by weight of quinone, 8500 parts by weight of styrene, and 1 part by weight of p-benzoquinone.

[0025] The preparation method of the unsaturated polyester resin for bulk molding compound is:

[0026] a) When the nitrogen flow rate is 1.5 ~ 1.8m 3 Under the condition of 1,2 propylene glycol, diethylene glycol, 3 / 5 polymerization inhibitor, phthalic anhydride, maleic anhydride and antioxidant, the temperature is raised to 205°C at a rate of 10-12°C / h, and the temperature is kept React for 5-8 hours, react until the acid value reaches 39-45mgKOH / g, carry out dehydration under reduced pressure until the acid value reaches 31-37mgKOH / g, then cool to 195°C, add the remaining polymerization inhibitor...

Embodiment 2

[0030] Formula: 2200 parts by weight of phthalic anhydride, 8000 parts by weight of maleic anhydride, 3500 parts by weight of diethylene glycol,

[0031] 4800 parts by weight of 1,2-propanediol, 3 parts by weight of triphenyl phosphite, 10 parts by weight of hydroquinone, 5 parts by weight of methylhydroquinone, 8800 parts by weight of styrene, and 1 part by weight of p-benzoquinone.

[0032] The preparation method of the unsaturated polyester resin for bulk molding compound is:

[0033] a) When the nitrogen flow rate is 1.5 ~ 1.8m 3 Under the condition of 1,2 propylene glycol, diethylene glycol, 3 / 5 polymerization inhibitor, phthalic anhydride, maleic anhydride and antioxidant, the temperature is raised to 205°C at a rate of 10-12°C / h, and the temperature is kept React for 5-8 hours, react until the acid value reaches 39-45mgKOH / g, carry out dehydration under reduced pressure until the acid value reaches 31-37mgKOH / g, then cool to 195°C, add the remaining polymerization inhi...

Embodiment 3

[0037] Formula: 2500 parts by weight of phthalic anhydride, 7500 parts by weight of maleic anhydride, 3700 parts by weight of diethylene glycol,

[0038] 4500 parts by weight of 1,2-propanediol, 4 parts by weight of triphenyl phosphite, 8 parts by weight of hydroquinone, 7 parts by weight of methylhydroquinone, 8500 parts by weight of styrene, and 1.5 parts by weight of p-benzoquinone.

[0039] The preparation method of the unsaturated polyester resin for bulk molding compound is:

[0040] a) When the nitrogen flow rate is 1.5 ~ 1.8m 3 Under the condition of 1,2 propylene glycol, diethylene glycol, 3 / 5 polymerization inhibitor, phthalic anhydride, maleic anhydride and antioxidant, the temperature is raised to 205°C at a rate of 10-12°C / h, and the temperature is kept React for 5-8 hours, react until the acid value reaches 39-45mgKOH / g, carry out dehydration under reduced pressure until the acid value reaches 31-37mgKOH / g, then cool to 195°C, add the remaining polymerization in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com