Method for rapidly forming polylactic acid stereocomplex

A technology of stereocomplexes and polylactic acid, applied in the field of rapid formation of polylactic acid stereocomplexes, can solve problems such as inability to eliminate polylactic acid homogeneous crystals, inability to suppress polylactic acid homogeneous crystals, and low rate of stereocomplexes , to achieve the effect of fast speed, strong mobility and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for rapidly forming a polylactic acid stereocomplex, the method comprising the following steps:

[0042] (1) Dissolve D-polylactic acid and nanocellulose-grafted L-polylactic acid with a comb-like structure in chloroform at room temperature according to a weight ratio of 33:67 to obtain a mixture; The optical purity of lactic acid is 99%;

[0043] (2) removing the solvent from the mixture at 40° C. to obtain a polylactic acid / cellulose nanocomposite material, that is, to obtain the polylactic acid stereocomplex of the present invention;

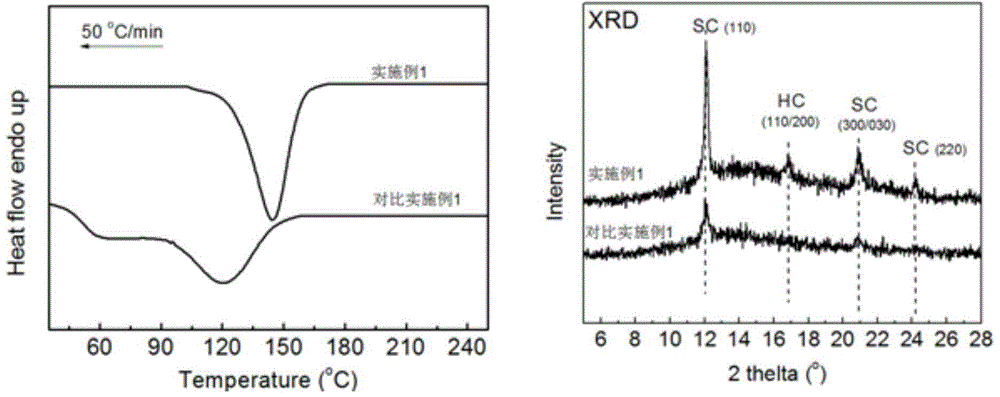

[0044] Gained polylactic acid stereocomplex DSC cooling process crystallization curve and the XRD spectrogram after crystallization are as follows image 3 As shown, the crystallization curve of the polylactic acid stereocomplex at 175°C in the DSC isothermal process is shown in Figure 4 , the polarizing microscope photo of isothermal crystallization of polylactic acid stereocomposite at 175°C Figure 5 As shown, the atomi...

Embodiment 2

[0056] A method for rapidly forming a polylactic acid stereocomplex, the method comprising the following steps:

[0057] (1) Dissolve D-polylactic acid and nanocellulose-grafted L-polylactic acid with a comb-like structure in chloroform at room temperature according to a weight ratio of 30:70 and stir thoroughly to obtain a mixture; The optical purity of lactic acid is 99.5%;

[0058] (2) removing the solvent from the mixture at 40° C. to obtain a polylactic acid / cellulose nanocomposite material, that is, to obtain the polylactic acid stereocomplex of the present invention;

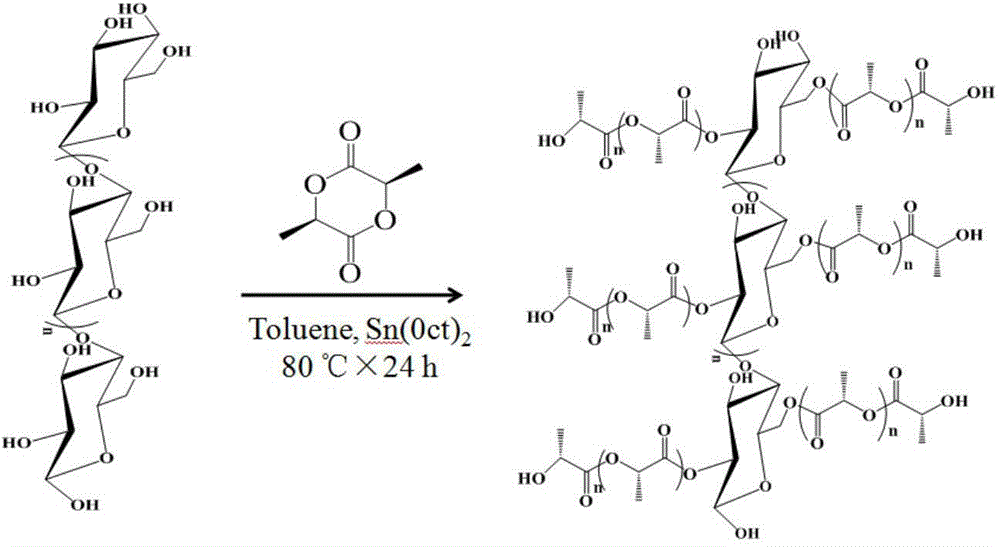

[0059] refer to figure 1 , the preparation method of the nanocellulose grafted L-polylactic acid is:

[0060] (1) first nanocellulose and L-lactide are uniformly dispersed in xylene respectively according to the weight ratio of 1:25, and the solution is blended to obtain a uniform mixture;

[0061] (2) Add catalyst tin protochloride (1.5% for the weight fraction of L-lactide) in the mixture again, reac...

Embodiment 3

[0065] A method for rapidly forming a polylactic acid stereocomplex, the method comprising the following steps:

[0066] (1) Dissolve the L-polylactic acid and the nanocellulose-grafted D-polylactic acid with a comb-like structure in a weight ratio of 40:60 at room temperature in dichloromethane to obtain a mixture; The optical purity of polylactic acid is 98%;

[0067] (2) removing the solvent from the mixture at 50° C. to obtain a polylactic acid / cellulose nanocomposite material, that is, to obtain the polylactic acid stereocomplex of the present invention;

[0068] The preparation method of the nanocellulose grafted D-polylactic acid is:

[0069] (1) first nanocellulose and D-lactide are uniformly dispersed in xylene respectively according to the weight ratio of 1:25, and the solution is blended to obtain a uniform mixture;

[0070] (2) Add the catalyst stannous octoate (3% of the weight fraction of D-lactide) in the mixture again, the reaction temperature is 80 DEG C, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com