Xanthochromia-resistant UV paint for external wall sheet material and preparation method of xanthochromia-resistant UV paint

A technology for yellowing resistance and sheet metal, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of slow drying, unenvironmental protection and poor performance of water-based coatings, and achieve good yellowing resistance, excellent water resistance, and good adhesion. focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

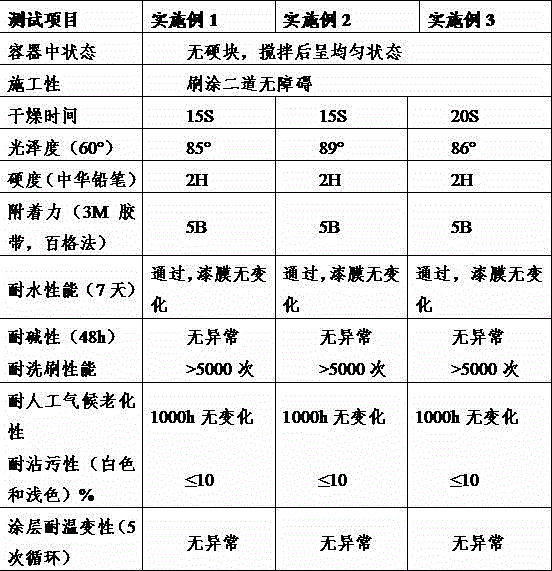

Examples

Embodiment 1

[0040] A kind of anti-yellowing UV paint, is made up of following raw material of percentage by weight:

[0041] Aliphatic polyurethane acrylate (Changxing 6106) 40%;

[0042] Acrylate (Changxing 6530B-40) 12%;

[0043] 1,6-hexanediol diacrylate (Changxing EM221) 15%;

[0044] Tripropylene glycol diacrylate (Changxing EM223) 15%;

[0045] 2-Hydroxy-2-methyl-1-phenyl-1-propanone 5%;

[0046] o-Hydroxybenzophenones 1%;

[0047] Leveling agent (BYK333) 1.0%;

[0048] Defoamer (BYK020) 0.5%;

[0049] Leveling control agent (EFKA5010) 0.5%;

[0050] Mix solvent 10%.

[0051] Add the aliphatic urethane acrylate, acrylate, reactive diluent, and solvent according to the above weight percentage into the container, stir thoroughly, then add the above weight percentage of auxiliary agent and photoinitiator, and fully stir.

Embodiment 2

[0053] A kind of anti-yellowing UV paint, is made up of following raw material of percentage by weight:

[0054] Aliphatic polyurethane acrylate (Changxing 6106) 30%;

[0055] Acrylate (Changxing 6530B-40) 20%;

[0056] 1,6-hexanediol diacrylate (cytec HDDA) 15%;

[0057] Trimethylol Triacrylate 15%;

[0058] Benzophenone 6%;

[0059] Salicylates 2%;

[0060] Leveling agent (BYK333) 1.0%;

[0061] Defoamer (BYK020) 0.5%;

[0062] Leveling control agent (EFKA5010) 0.5%;

[0063] Mix solvent 10%.

[0064] Add the aliphatic urethane acrylate, acrylate, reactive diluent, and solvent according to the above weight percentages into the container, stir well, then add the above weight percentages of additives and photoinitiators, and stir well to obtain a yellowing-resistant UV coating.

Embodiment 3

[0066] A kind of anti-yellowing UV paint, is made up of following raw material of percentage by weight:

[0067] Aliphatic urethane acrylate (Cytec EB284) 35%;

[0068] Acrylate (Cytec EB710) 10%;

[0069] 1,6-hexanediol diacrylate (cytec HDDA) 15%;

[0070] Tripropylene glycol diacrylate (Cytec TPGDA) 10%;

[0071] Benzoin Dimethyl Ether 6%;

[0072] Triazines 2%;

[0073] Leveling agent (BYK333) 1.0%;

[0074] Defoamer (BYK020) 0.5%;

[0075] Leveling control agent (EFKA5010) 0.5%;

[0076] Mix solvent 20%.

[0077] Add the aliphatic urethane acrylate, acrylate, reactive diluent, and solvent according to the above weight percentages into the container, stir well, then add the above weight percentages of additives and photoinitiators, and stir well to obtain a yellowing-resistant UV coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com