Method for detecting volatile components in tobacco leaves

A technology for volatile components and detection methods, applied in the field of detection of volatile components in tobacco leaves, can solve problems such as no literature reports, and achieve the effects of simple and rapid sample pretreatment, high sensitivity, and avoiding the pretreatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 0.5g of shredded tobacco sample (produced in Hunan) into a conical flask, add 20mL of distilled water, plug it with a glass stopper, and let it stand overnight. The solution was transferred to a three-necked flask and the solution was filled to 40 mL with distilled water.

[0046]Put the extraction fiber head into the extraction handle to form a manual SPME sample injector, insert it into the vaporization chamber with a temperature of 250°C, retract the fiber head after aging for 30 minutes, and pull out the sample injector.

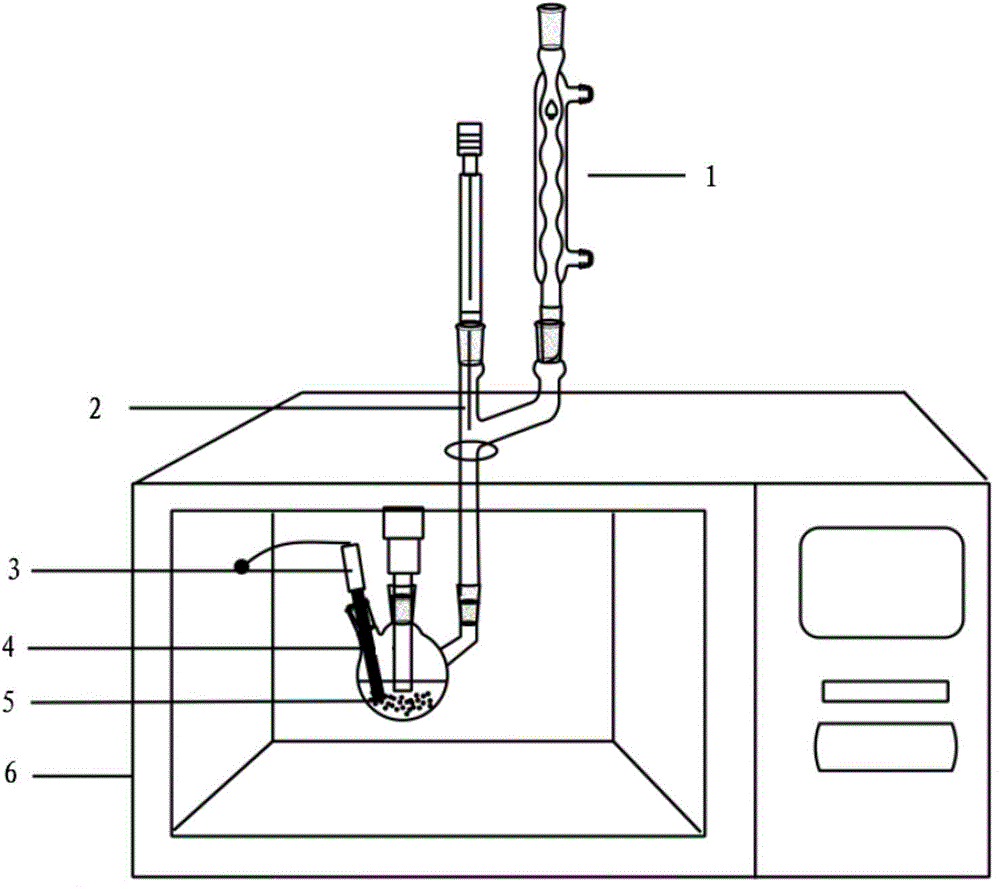

[0047] Set the microwave power to 600W, the extraction time to 10min, use 50μm / 30μm DVB / CAR / P DMS fiber coating, insert the solid-phase microextraction head into the self-made diaphragm (the diaphragm acts as a seal to prevent the gas phase volatiles from diffusing into the air) adsorption on top of the sample.

[0048] After the extraction was completed, the solid-phase microextraction needle was inserted into the GC inlet, and analyzed at...

Embodiment 2~4

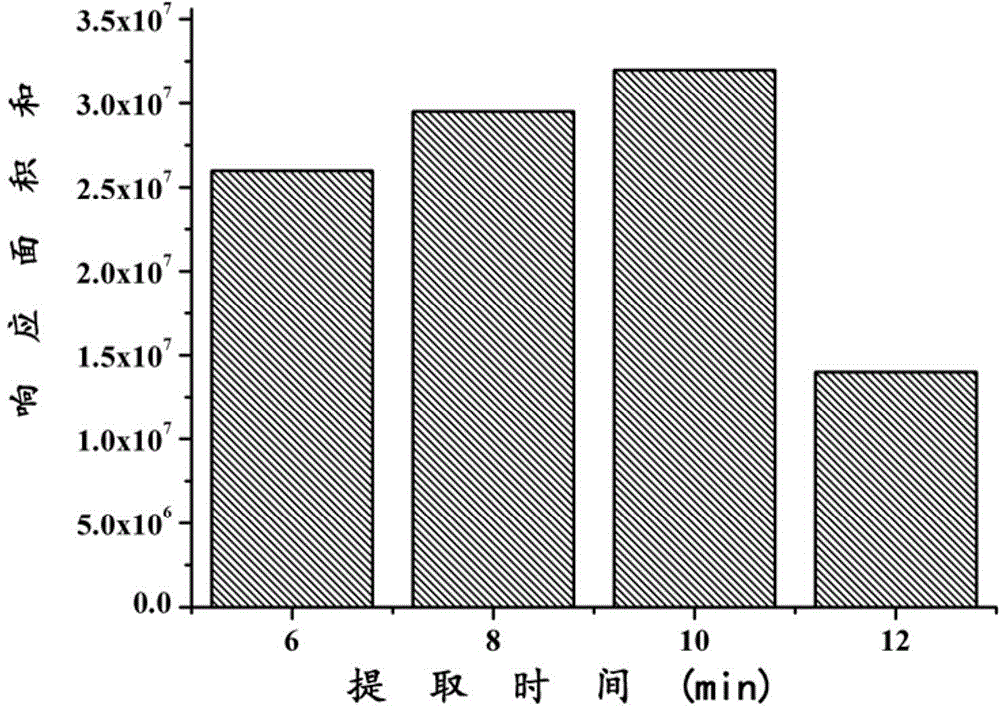

[0054] The difference with Example 1 is only: the extraction time is different, the extraction time of Examples 2~4 is successively 6min, 8min and 12min, the chromatographic total peak area of Example 1~4 is as follows figure 2 As shown, after the extraction time is greater than 10min, the total peak area has a downward trend, which is due to the fact that in a short period of time, the low-volatility components have been extracted, the extraction time is too long, and the electromagnetic radiation reduces the stability of the components, resulting in Components with poor thermal stability decompose.

Embodiment 5~7

[0056] The only difference from Example 1 is that the origins of the tobacco leaf samples are different.

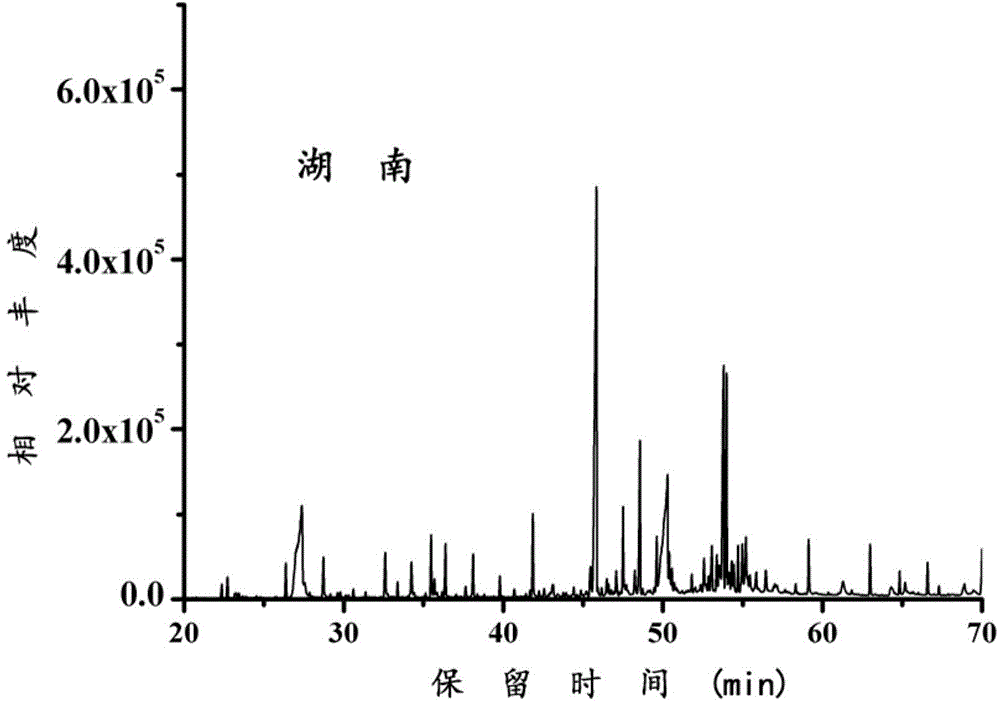

[0057] The total ion chromatogram of embodiment 1,5,6,7 gained is respectively as follows image 3 , Figure 4 , Figure 5 , Image 6 It can be seen from the figure that the peak positions of the volatile components of tobacco leaves from different origins are roughly similar, but the peak contents are quite different.

[0058] Through the tandem search of the chemical workstation NIST and WILEY mass spectral library, using the retention index and references to assist the mass spectral search for qualitative identification, Hunan, Guizhou, Yunnan and Zimbabwe identified 24, 28, 27 and 24 volatile components, respectively. The specific results are shown in Table 1. , Table 2, Table 3, Table 4.

[0059] Table 1

[0060]

[0061]

[0062]

[0063] Table 2

[0064]

[0065]

[0066] table 3

[0067]

[0068]

[0069]

[0070] Table 4

[0071] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com