Cartilago articularis vitrification cryoprotectant and cartilage preservation method

A technology for vitrification and freezing of articular cartilage, applied in the field of biomedicine, can solve the problems of low survival rate of chondrocytes and short storage time in vitro, and achieve the effects of improving the storage effect, prolonging the storage time, and expanding the promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

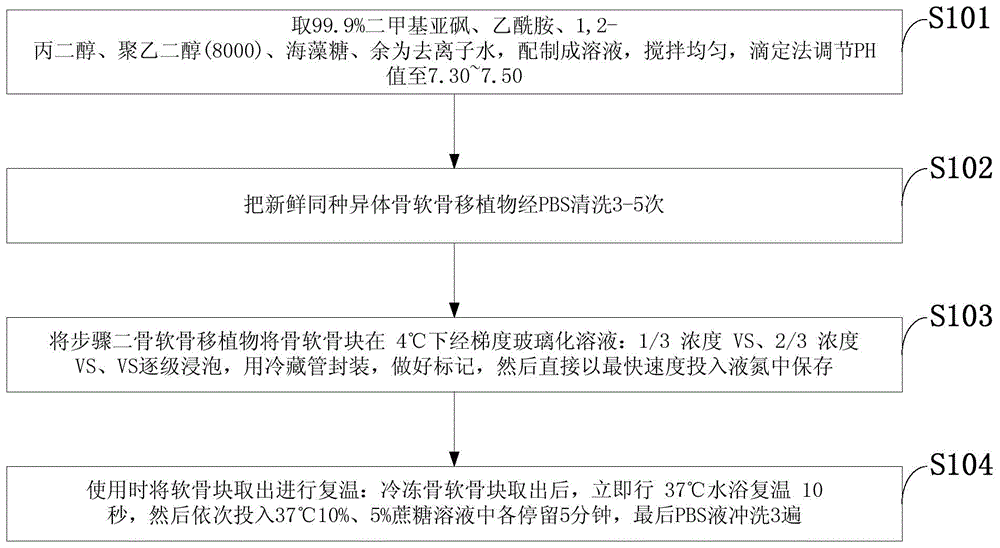

Embodiment 1

[0029] Example 1: Each 1000ml vitrification solution includes: 99.9% dimethyl sulfoxide 160ml, acetamide 125g, 1,2-propanediol 80ml, polyethylene glycol (8000) 30g, trehalose 40g, the rest is deionized water , prepare the raw materials into a solution, stir evenly, and adjust the pH value to 7.30-7.50; wash the fresh allogeneic osteochondral graft with phosphate buffer for 3-5 times; vitrify the osteochondral block at 4°C Solution: 1 / 3 concentration of vitrification protection solution, 2 / 3 concentration of vitrification protection solution, 3 / 3 concentration of vitrification protection solution, etc., soaked for 10 minutes in sequence, sealed in a refrigerated tube, marked, and then directly at the fastest speed Put into liquid nitrogen for storage. Rewarm the cartilage blocks at the 8th week: After taking out the frozen cartilage blocks, immediately rewarm them in a 37°C water bath for 10 seconds, then put them into 37°C 10% and 5% sucrose solutions for 5 minutes each, and f...

Embodiment 2

[0030] Example 2: Each 1000ml vitrification solution includes: 99.9% dimethyl sulfoxide 205ml, acetamide 155g, 1,2-propanediol 100ml, polyethylene glycol (8000) 60g, trehalose 60g, the rest is deionized water , prepare the raw materials into a solution, stir evenly, and adjust the pH value to 7.30-7.50; wash the fresh allogeneic osteochondral graft with phosphate buffer for 3-5 times; vitrify the osteochondral block at 4°C Solution: 1 / 3 concentration vitrification protection solution, 2 / 3 concentration vitrification protection solution, 3 / 3 vitrification protection solution, soaked step by step for 10 minutes, packaged in a refrigerated tube, marked well, and then put directly into it at the fastest speed Store in liquid nitrogen. Rewarm the cartilage blocks at the 8th week: After taking out the frozen cartilage blocks, immediately rewarm them in a 37°C water bath for 10 seconds, then put them into 37°C 10% and 5% sucrose solutions for 5 minutes each, and finally phosphate buf...

Embodiment 3

[0031] Example 3: Each 1000ml vitrification solution includes: 225ml of 99.9% dimethyl sulfoxide, 190g of acetamide, 115ml of 1,2-propanediol, 70g of polyethylene glycol (8000), 90g of trehalose, and the rest is deionized water , prepare the raw materials into a solution, stir evenly, and adjust the pH value to 7.30-7.50; wash the fresh allogeneic osteochondral graft with phosphate buffer for 3-5 times; vitrify the osteochondral block at 4°C Solution: 1 / 3 concentration of vitrification protection solution, 2 / 3 concentration of vitrification protection solution, 3 / 3 concentration of vitrification protection solution, etc., soaked for 10 minutes in sequence, sealed in a refrigerated tube, marked, and then directly at the fastest speed Put into liquid nitrogen for storage. Rewarm the cartilage blocks at the 8th week: After taking out the frozen cartilage blocks, immediately rewarm them in a 37°C water bath for 10 seconds, then put them into 37°C 10% and 5% sucrose solutions for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com