High-reliability welding method for lead ceramic thermal resistor

A technology of thermistor and welding method, which is applied in the field of lead ceramic thermistor welding and ceramic thermistor welding, can solve the problems such as the decrease of solder dissolution force, achieve the enhancement of solder dissolution force, and ensure long-term high pressure resistance , the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

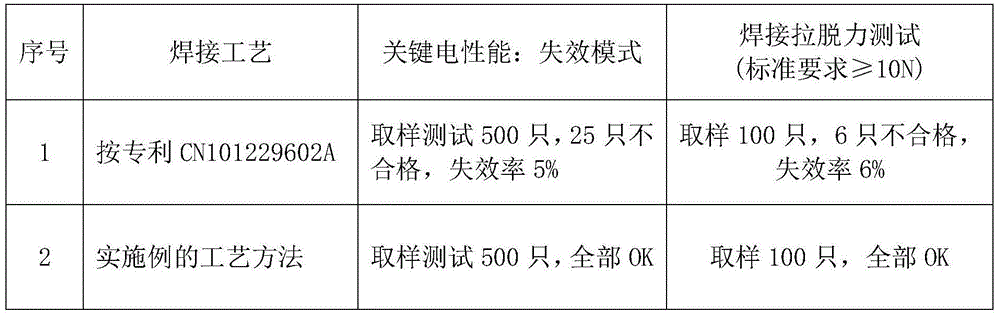

Examples

Embodiment 1

[0010] Embodiment 1. The specific manufacturing process of the ceramic thermistor involved in this embodiment is as follows. The substrate is obtained through batching, wet ball milling, pre-firing, secondary wet ball milling, granulation, molding, and sintering. After the substrate is cleaned, the electrodes are sputtered for sorting. Then use special welding equipment to weld the chip and the lead wire. The solder is made of SnCu alloy tin (containing 1-3% copper), and the wire material is tinned copper wire or tinned copper-clad steel wire. The outer diameter of the wire: Φ0.5~ 1.0mm.

[0011] The steps for welding are

[0012] 1. Wire bonding adjustment: through the selection of different molds, the P width between the leads is controlled to meet the product size requirements.

[0013] 2. Tin adjustment: through the adjustment of the amount of tin in the solder joints, to ensure the reliability of the solder joints of the product.

[0014] 3. Adjustment of suction piece...

Embodiment 2

[0017] Embodiment 2. The specific manufacturing process of the ceramic thermistor involved in this embodiment is as follows. The substrate is obtained through batching, wet ball milling, pre-firing, secondary wet ball milling, granulation, molding, and sintering. After the substrate is cleaned, the electrodes are sputtered for sorting. Then use special welding equipment to weld the chip and the lead wire. The solder is made of SnCu alloy tin (containing 1-3% copper), and the wire material is tinned copper wire or tinned copper-clad steel wire. The outer diameter of the wire: Φ0.5~ 1.0mm.

[0018] The steps for welding are

[0019] 1. Wire bonding adjustment: through the selection of different molds, the P width between the leads is controlled to meet the product size requirements.

[0020] 2. Tin adjustment: through the adjustment of the amount of tin in the solder joints, to ensure the reliability of the solder joints of the product.

[0021] 3. Adjustment of suction piece...

Embodiment 3

[0024] Embodiment 3. The specific manufacturing process of the ceramic thermistor involved in this embodiment is as follows. The substrate is obtained through batching, wet ball milling, pre-firing, secondary wet ball milling, granulation, molding, and sintering. After the substrate is cleaned, the electrodes are sputtered for sorting. Then use special welding equipment to weld the chip and the lead wire. The solder is made of SnCu alloy tin (containing 1-3% copper), and the wire material is tinned copper wire or tinned copper-clad steel wire. The outer diameter of the wire: Φ0.5~ 1.0mm.

[0025] The steps for welding are

[0026] 1. Wire bonding adjustment: through the selection of different molds, the P width between the leads is controlled to meet the product size requirements.

[0027] 2. Tin adjustment: through the adjustment of the amount of tin in the solder joints, to ensure the reliability of the solder joints of the product.

[0028] 3. Adjustment of suction piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com