Composite electrolyte membrane, lithium metal battery and preparation method of composite electrolyte membrane

A composite electrolyte membrane and solid electrolyte technology, which is applied in the preparation of lithium metal batteries and composite electrolyte membranes, and in the field of composite electrolyte membranes, can solve problems such as reducing the cycle performance of lithium metal batteries, reducing the high-voltage resistance of electrolytes, and short-circuiting lithium metal batteries. , to achieve the effect of ensuring high pressure resistance, good applicability, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

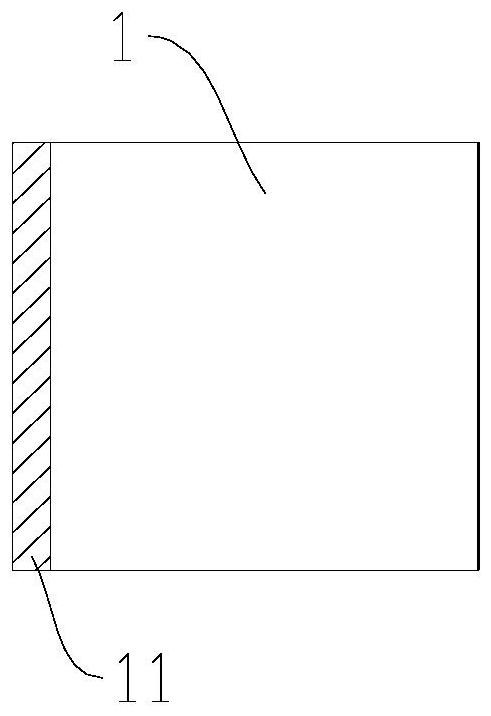

[0055] Such as figure 1As shown, a composite electrolyte membrane includes an intermediate layer 1, the intermediate layer 1 is a solid electrolyte or a diaphragm, and the side of the intermediate layer 1 used to connect with the positive electrode sheet has a first coating layer 11, and the first coating layer 11 is formed by the first The slurry is coated and dried, and the first slurry includes a first resin containing difluorophosphate, a first polymer binder and a first organic solvent.

[0056] In this embodiment, the first resin accounts for 3-20% by weight of the first slurry, and the first polymer binder accounts for 1-10% by weight of the first slurry.

[0057] In this embodiment, the first polymer binder is one or more of polyvinylidene fluoride (PVDF), polyethylene, polyvinylidene chloride, polypropylene, and polyacrylonitrile, and the first organic solvent is NMP , acetone, DMF and DMSO in one or more.

[0058] The method for making the above-mentioned composite...

Embodiment 2

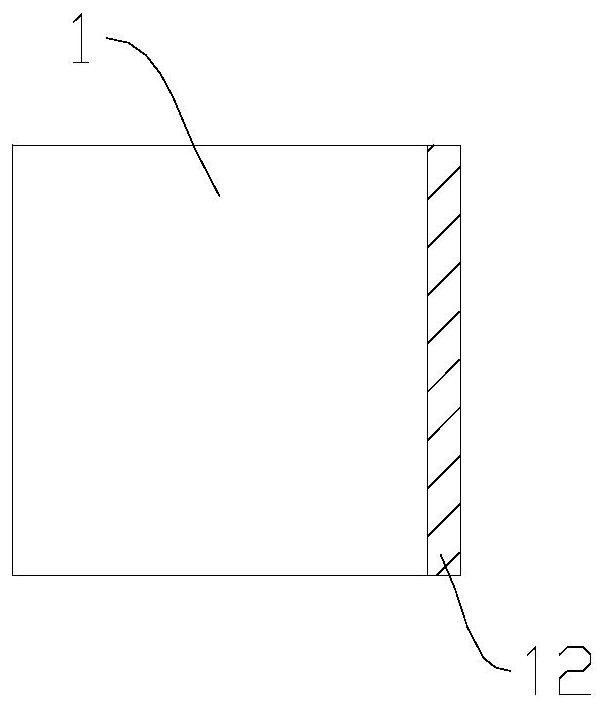

[0066] Such as figure 2 As shown, a composite electrolyte membrane includes an intermediate layer 1, the intermediate layer 1 is a solid electrolyte or a diaphragm, and the side of the intermediate layer 1 used to connect with the negative electrode sheet has a second coating layer 12, and the second coating layer 12 is composed of a second The slurry is formed after being coated and dried, and the second slurry includes a second resin containing nitrate, a second polymer binder and a second organic solvent.

[0067] In this embodiment, the second resin accounts for 3-20% by weight of the second slurry, and the second polymer binder accounts for 1-10% by weight of the second slurry.

[0068] In this embodiment, the second polymer binder is one or more of polyvinylidene fluoride, polyethylene, polyvinylidene chloride, polypropylene, and polyacrylonitrile, and the second organic solvent is NMP, acetone, One or more of DMF and DMSO.

[0069] The method for making the above-men...

Embodiment 3

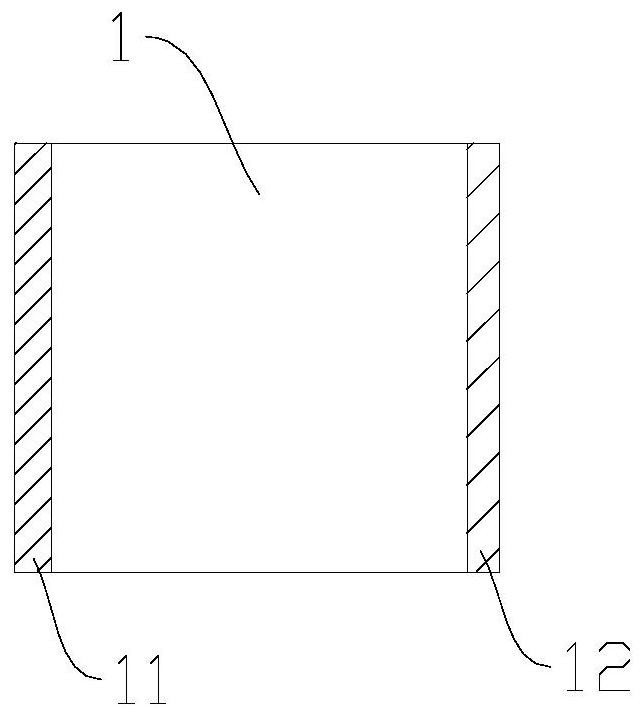

[0077] Such as image 3 As shown, a composite electrolyte membrane includes an intermediate layer 1, the intermediate layer 1 is a solid electrolyte or a diaphragm, the side of the intermediate layer 1 used to connect with the positive electrode sheet has a first coating layer 11, and the intermediate layer 1 is used to connect with the negative electrode sheet One side of the connection has a second dressing layer 12, the first dressing layer 11 is formed by drying the first slurry after coating, the first slurry includes the first resin containing difluorophosphate, the first polymer binder and The first organic solvent, the second dressing layer 12 is formed by drying the second slurry after coating, and the second slurry includes a second resin containing nitrate, a second polymer binder and a second organic solvent.

[0078] In this embodiment, the first resin accounts for 3-20% of the first slurry by weight, the first polymer binder accounts for 1-10% of the first slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com