A method for constructing calcium carbonate superhydrophobic structure on the surface of bamboo wood

A wood surface, calcium carbonate technology, applied in wood treatment, wood impregnation, wood impregnation, etc., to achieve the effect of stable contact angle, high stability and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of mixed liquid: take calcium hydroxide 100g, water 70g, carbonic acid 0.01g, adhesion promoter 0.01g, silane coupling agent 3g, palm oil 5g, oil wax 10g, gum 3g, calcium ricinoleate 0.001g , after mixing evenly, the mixed liquid is obtained;

[0027] (2) Put the bamboo into the mixed solution obtained in step (1), stir for 300 minutes, the stirring speed is 1 rpm, and the temperature is kept at 75±2°C to obtain the bamboo loaded with calcium carbonate superhydrophobic structure;

[0028] (3) the bamboo material that step (2) gained is loaded with calcium carbonate superhydrophobic structure, cleans 3 times with corn oil, then washes with water 3 times, moisture content is dried to 29%, obtains the calcium carbonate that is loaded with superhydrophobic structure Bamboo specimens.

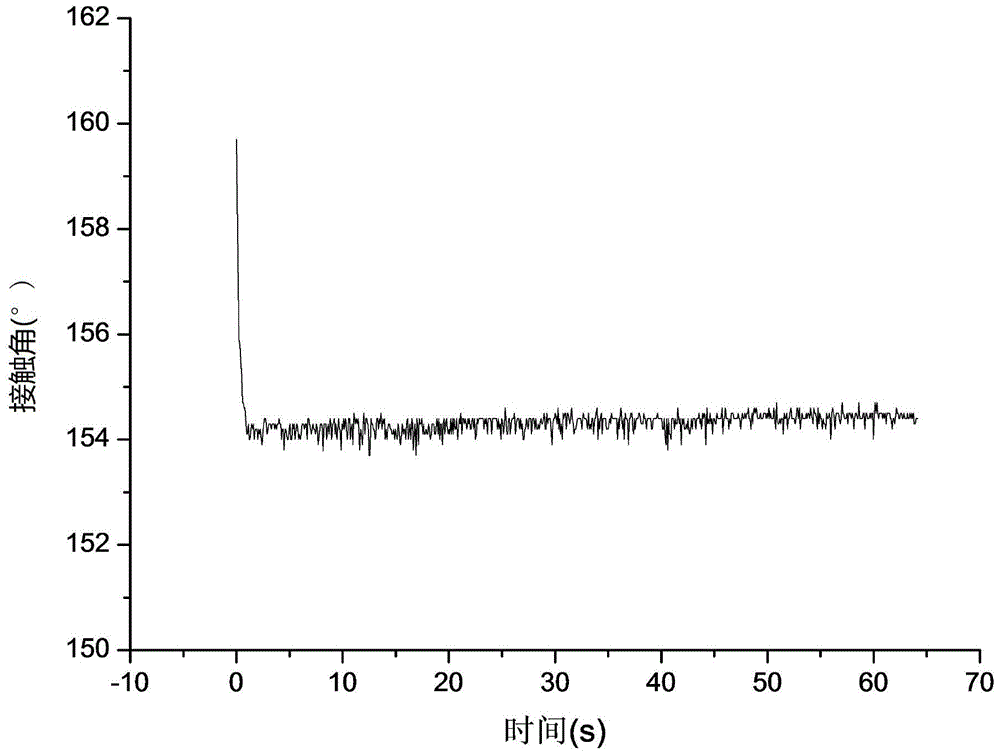

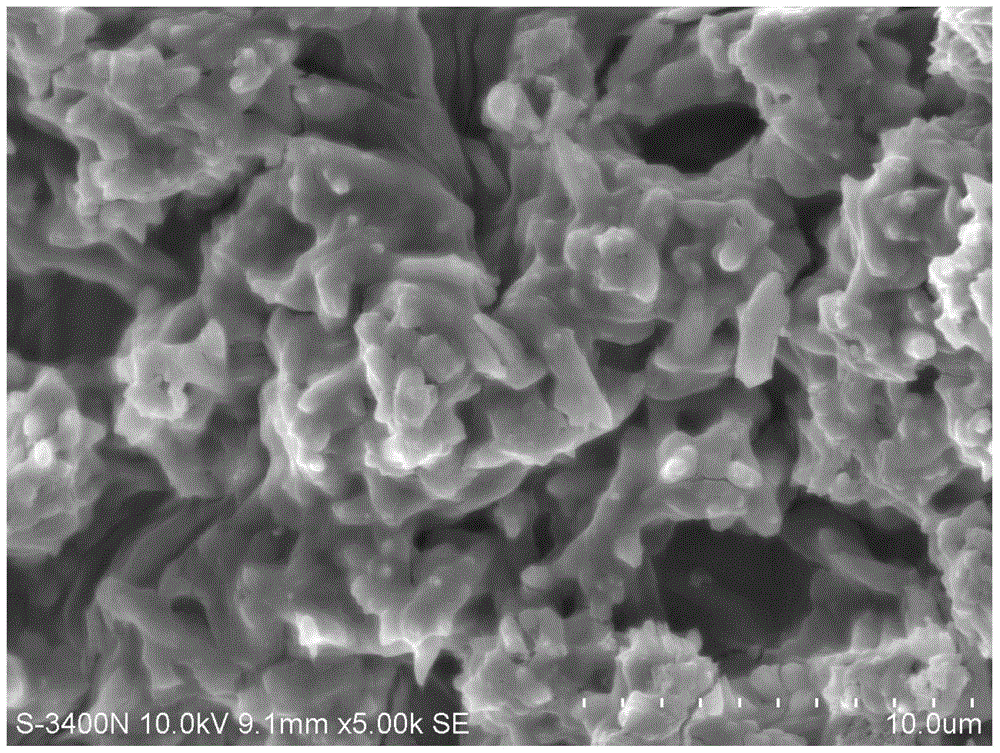

[0029] result:

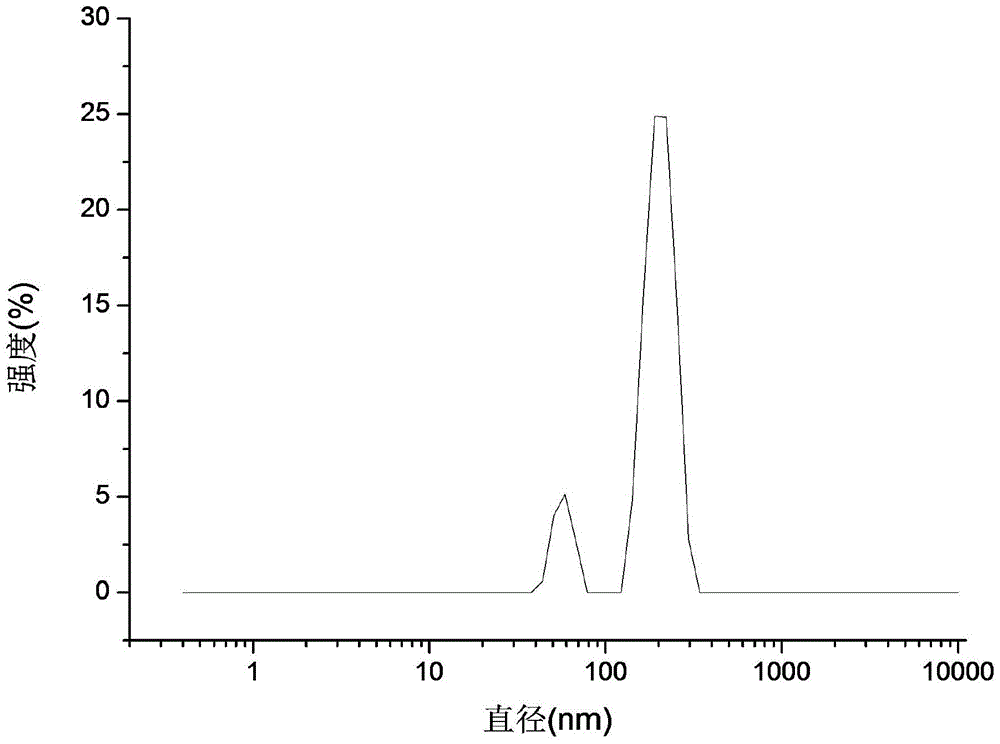

[0030] (1) Calcium carbonate particle size in the mixture

[0031] Measurement results such as figure 1 shown. It can be seen that the particle diameters...

Embodiment 2

[0037] (1) Preparation of mixed liquid: take calcium hydroxide 100g, water 0.1g, carbonic acid 12g, adhesion promoter 5g, silane coupling agent 0.001g, lard 20g, oil wax 0.001g, gum 10g, calcium ricinoleate 4g , after mixing evenly, the mixed liquid is obtained;

[0038] (2) Put the bamboo sieve into the mixture obtained in step (1), stir for 200 minutes, the stirring speed is 5000 rpm, and the temperature is kept at 5±2°C to obtain the bamboo sieve loaded with calcium carbonate superhydrophobic structure;

[0039] (3) The bamboo sieve loaded with calcium carbonate superhydrophobic structure obtained in step (2) is washed 5 times with canola oil, then washed 3 times with water, and the moisture content is dried to 1%, and the superhydrophobic structure is loaded. The bamboo mist test piece of calcium carbonate.

[0040] result:

[0041] The testing conditions of sample contact angle and rolling angle are the same as in Example 1. The results show that the contact angle of t...

Embodiment 3

[0043](1) Preparation of mixed liquid: take calcium hydroxide 100g, water 25g, carbonic acid 35g, adhesion promoter 20g, silane coupling agent 1g, cottonseed oil 0.01g, oil wax 3g, gum 0.001g, calcium ricinoleate 10g , after mixing evenly, the mixed liquid is obtained;

[0044] (2) Put the bamboo wood-based panel into the mixed solution obtained in step (1), stir for 100 minutes, the stirring speed is 10,000 rpm, and the temperature is kept at 25±2°C to get the bamboo artificial board loaded with calcium carbonate superhydrophobic structure. plate;

[0045] (3) the bamboo wood-based panel that step (2) gained is loaded with superhydrophobic structure of calcium carbonate, washes 1 time with soybean oil, then washes with water 5 times, moisture content is dried to 25%, obtains the carbonic acid that is loaded with superhydrophobic structure Calcium-based bamboo-based panel specimens.

[0046] result:

[0047] The testing conditions of sample contact angle and rolling angle a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com