Ceramic inner thread machining mold

A technology of threads and thread segments, which is applied in the field of C/SiC composite ceramic pre-embedded external thread molds, can solve problems such as damage, tool wear, and ceramic slag, and achieve the effects of reducing metal residue, slow flow speed, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

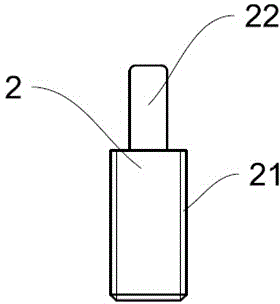

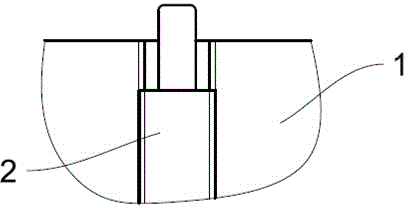

[0017] The structure of the C / SiC composite ceramic pre-embedded external thread mold of the present invention is as follows: figure 1 As shown, the lower end of the external thread mold 2 is an external thread segment 21, the screw-in end of the external thread segment 21 is chamfered, a flat handle 22 protrudes above the external thread segment 21, and the C / SiC composite ceramics are pre-embedded outside. The schematic diagram of the structure of the thread mold during use is as follows figure 2 As shown, the external thread mold 2 is screwed into the thread to be processed of the ceramic mold 1 to be sintered, and a threaded hole is formed during the process of screwing the external thread mold 2 into the ceramic mold 1 to be sintered.

Embodiment 2

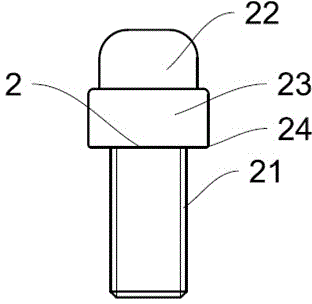

[0019] The structure of the C / SiC composite ceramic pre-embedded external thread mold of the present invention is as follows: image 3 As shown, the external thread mold 2 in this embodiment has a boss 23 between the external thread belt and the handle, the boss 23 is an annular boss, and an arc transition is adopted at the intersection of the two sides of the boss. Driven by the rotation of the external thread segment 21, such as Figure 4 As shown, a countersunk hole can be formed on the ceramic mold, and at the same time, since the two intersecting surfaces of the countersunk hole are arc transitions, the local stress in the sintering molding process can be reduced, and the molding quality can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com