Vehicle carpet high in sound absorption performance and manufacturing method thereof

A carpet and performance technology, applied in the field of textile manufacturing, can solve the problems of reduced sound absorption, low sound absorption, low comfort, etc., and achieve the effects of increasing sound absorption coefficient, improving sitting comfort, and improving sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

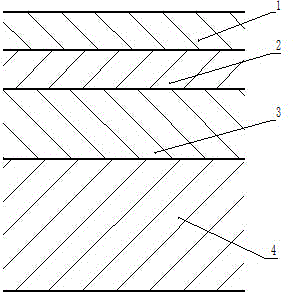

[0037] The following combination Attached picture Further illustrate the structure of the present invention:

[0038] see icon 2. From top to bottom, the car carpet includes polyester blank 1, PE adhesive layer 2, cotton and polyester composite sound-absorbing felt 3 and sound-absorbing foam 4 composite. Wherein the density of polyester blank 1 is 650g / m 2 , the density of PE adhesive layer 2 is 300g / m 2 , the composite sound-absorbing pad 3 is made of a mixture of 30% cotton fiber and 70% polyester fiber, and the density of cotton fiber is 195g / m 2, Polyester fiber density is 455g / m 2 , the sound-absorbing foam is PUR foam with a density of 50kg / m 3 .

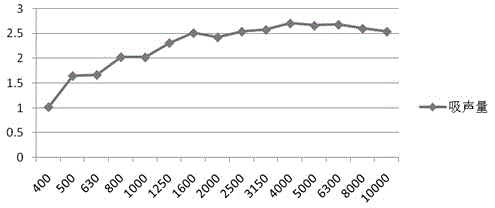

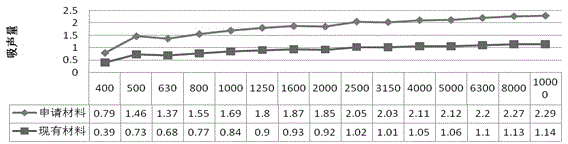

[0039] Compared with the sound absorption of the existing traditional carpet materials, the high sound-absorbing material is from image 3 It can be seen that the high sound absorption material has a higher sound absorption than the existing traditional technology material.

[0040] The above-mentioned carpet is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com