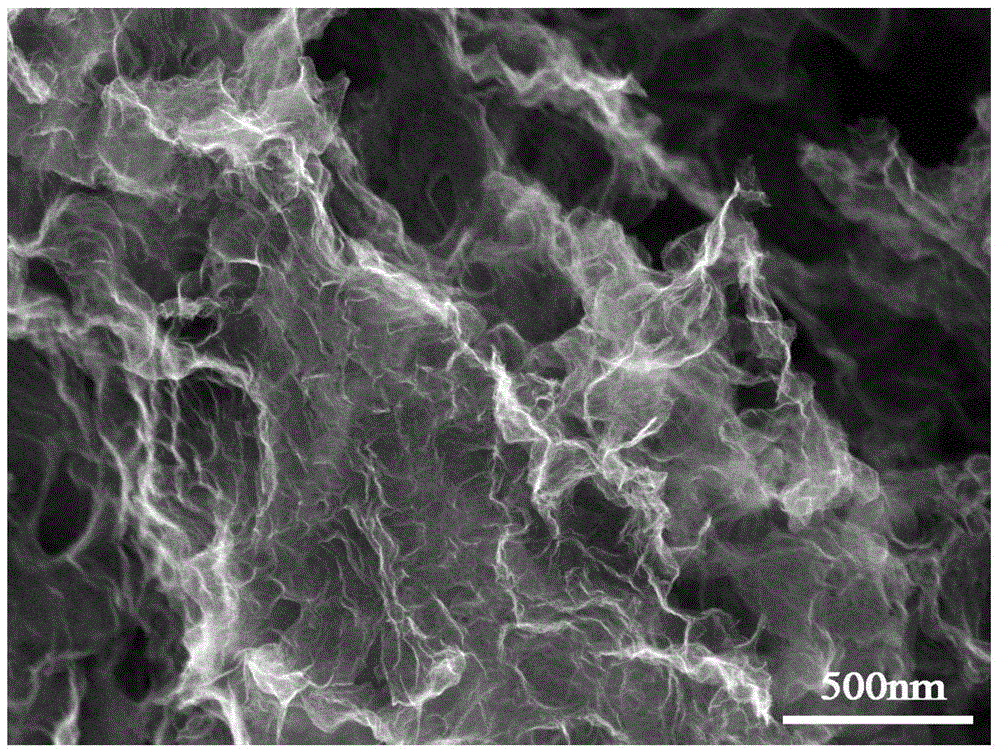

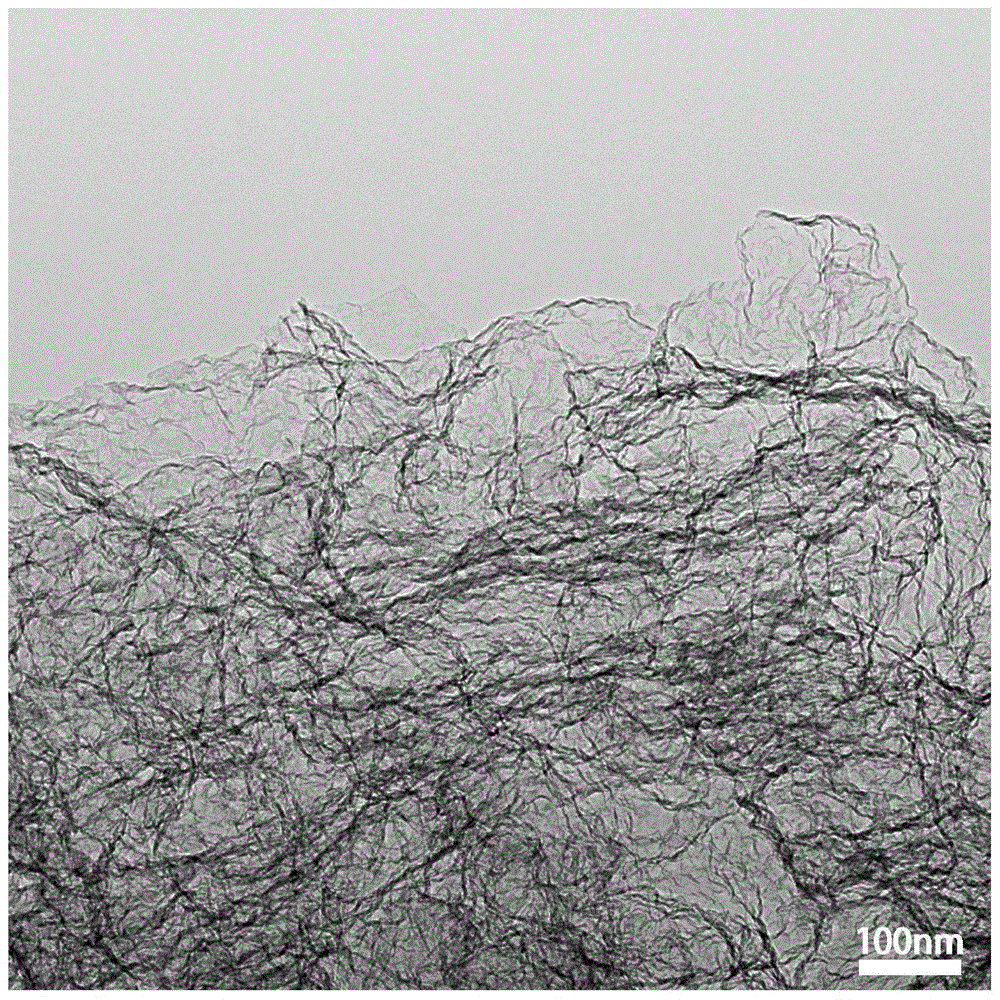

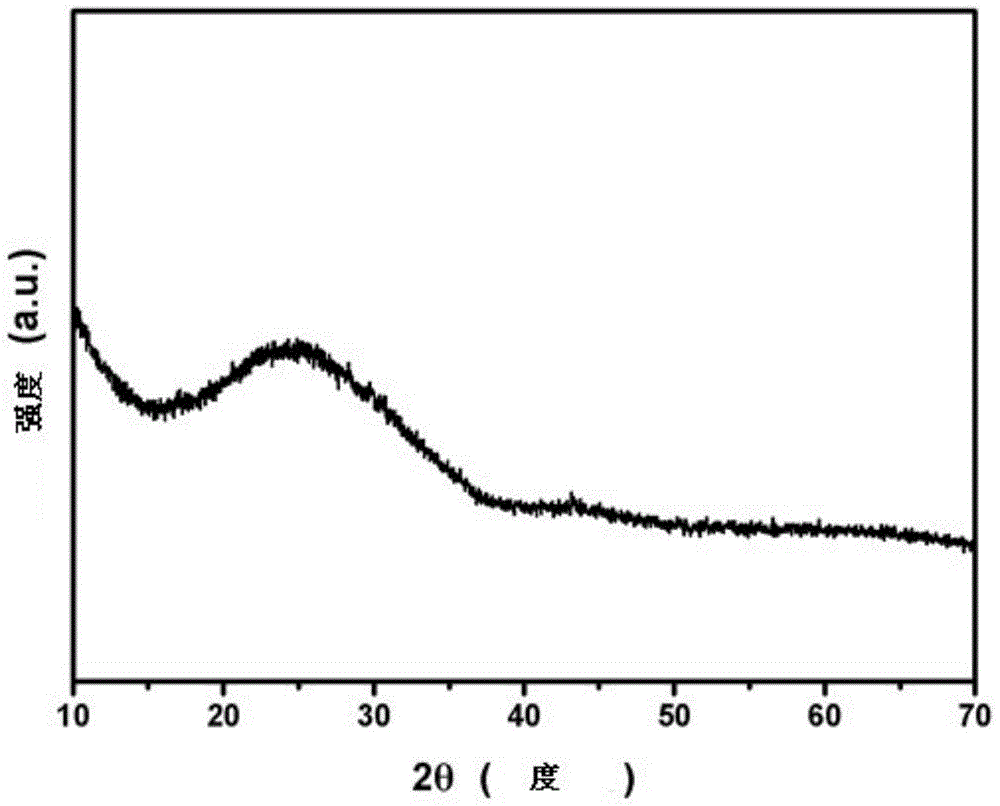

One-step in situ preparation of doped graphene with tunable nitrogen content and species

A technology of in-situ preparation and nitrogen content, applied in the field of doped graphene, can solve the problems of complex nitrogen-doped graphene preparation process, high preparation cost, controllable content and types of difficult nitrogen elements, etc., and achieve good catalytic stability. , large specific surface area, uniform effect of nitrogen doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: In this embodiment, a method for one-step in-situ preparation of doped graphene with adjustable nitrogen content and type is carried out according to the following steps:

[0024] 1. Put 1-500g of carbon nitride in a quartz tube sealed at one end, wherein the inner diameter of the quartz tube is φ=5-100mm, length=20cm, a cylindrical quartz plug is placed at the open end, and the outer surface of the quartz plug is Diameter φ = 4 ~ 99mm, length = 5cm, the difference between the inner diameter of the quartz tube and the outer diameter of the quartz plug is 1mm;

[0025] 2. Put the quartz tube with carbon nitride in the tube furnace, and then vacuum the tube furnace to 8×10 -4 ~9×10 -4 Pa, and then feed a flow rate of 50 to 90 sccm shielding gas into the tube furnace;

[0026] 3. Heat the tube furnace treated in step 2 to 740-750°C at a rate of 1-5°C / min, and then keep it warm for 5-120min to obtain nitrogen-doped graphene;

[0027] 4. Heat the tube furnac...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that the protective gas described in step 2 is high-purity argon or high-purity nitrogen. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 3, the tube furnace treated in Step 2 is heated to 740° C. at a rate of 2° C. / min. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com