Low-temperature calcining technology for cement clinker

A low-temperature calcination and cement clinker technology, which is applied in clinker production, cement production, etc., can solve problems such as difficult adaptation, and achieve the effects of reducing burning coal consumption, reducing energy consumption, improving calciner capacity and operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

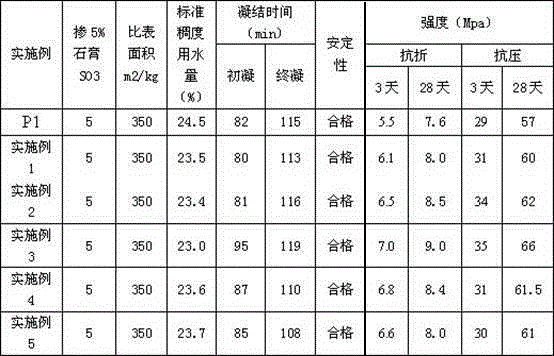

[0029] Using the raw material mix ratio of general portland cement, the three ratios of cement clinker are controlled as follows: KH (lime saturation): 0.90±0.02, SM (silicon ratio): 2.3±0.1, IM (aluminum ratio): 1.5 ±0.1. Add 0.5% control agent to prepare raw meal. The raw meal is pulverized by the raw meal mill and then enters the homogenization storage. The decomposition furnace controls the decomposition rate to 96%, and then calcines at a high temperature of 1380 ° C. The calcined clinker enters the clinker warehouse after cooling. The physical properties of the clinker are shown in Table 1.

[0030] Table 1

[0031]

Embodiment 2

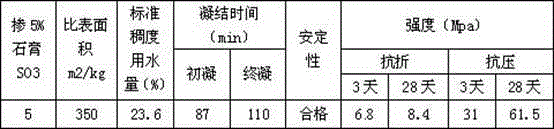

[0033] Using the raw material mix ratio of general portland cement, the three ratios of cement clinker are controlled as follows: KH (lime saturation): 0.90±0.02, SM (silicon ratio): 2.3±0.1, IM (aluminum ratio): 1.5 ±0.1. Add 1.0% control agent to prepare raw meal. The raw meal is pulverized by the raw meal mill and enters the homogenization storage. The decomposition furnace controls the decomposition rate to 96%, and then calcines at a high temperature of 1360°C. The calcined clinker enters the clinker warehouse after cooling. The physical properties of the clinker are shown in Table 2.

[0034] Table 2

[0035]

Embodiment 3

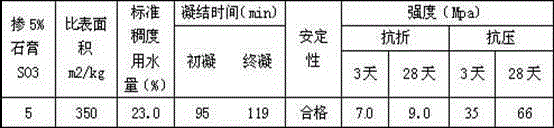

[0037] Using the raw material mix ratio of general portland cement, the three ratios of cement clinker are controlled as follows: KH (lime saturation): 0.90±0.02, SM (silicon ratio): 2.3±0.1, IM (aluminum ratio): 1.5 ±0.1. Add 2.2% control agent to prepare raw meal. The raw meal is ground by the raw meal mill and then enters the homogenization storage. The decomposition furnace controls the decomposition rate to 97%, and then calcines at a high temperature of 1340 ° C. The calcined clinker enters the clinker warehouse after cooling. The physical properties of the clinker are shown in Table 3.

[0038] table 3

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com