Water-vapor-resisting inflaming retarding PVC protecting sleeve material

A sheath material, water vapor technology, applied in the direction of plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of unqualified thermal deformation, rising costs, and difficulty in meeting product performance requirements, and achieve stable electrical performance. The effect of improving compactness and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

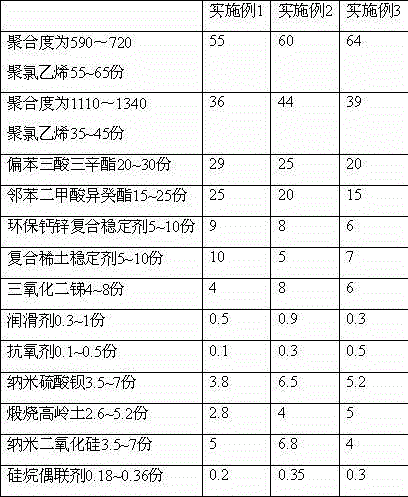

[0027] Embodiments 1 to 3: A water vapor-resistant flame-retardant PVC sheath material, the flame-retardant PVC sheath material is composed of the following components by weight as shown in Table 1:

[0028] Table 1

[0029]

[0030] All the above are parts by weight.

[0031] The above-mentioned silane coupling agent is vinyl tris(β-methoxyethoxy) silane, vinyl trimethoxy silane or γ-glycidyl etheroxypropyl trimethoxy silane.

[0032] The above-mentioned silane coupling agent is vinyl tris (β-methoxyethoxy) silane, vinyl trimethoxy silane and γ-glycidyl etheroxypropyl trimethoxy silane mixed in a ratio of 10:5:3 by weight .

[0033] Above-mentioned lubricant embodiment 1 is polyethylene wax, lubricant embodiment 2 is stearic acid, lubricant embodiment 3 is the compound of polyethylene wax and stearic acid.

[0034] The above antioxidant embodiment 1 is tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com