Paint for projection and preparation method of paint

A coating and projection technology, applied in the coating and other directions, can solve the problem of additional purchase of the curtain, and achieve the effect of improving the projection effect, increasing the gain, and improving the reflection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

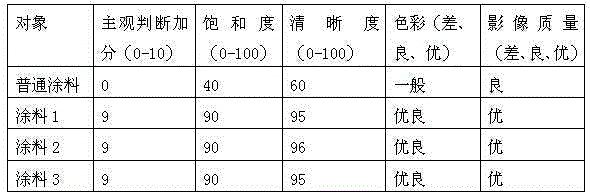

Examples

Embodiment 1

[0019] Example 1 Coating 1

[0020] In the first step, 25g of acrylic acid, 35g of resin and 3g of titanium dioxide were mixed, and stirred in a stirring tank for 60 minutes to obtain a mixture 1;

[0021] In the second step, take 2 g of microcrystalline cellulose, 4 g of cellulose ether and 0.2 g of N,N-dimethylethanolamine, add the mixture 1 obtained in the first step, and continue stirring for 35 minutes to obtain a mixture 2;

[0022] In the third step, take 2g of borosilicate, 0.5g of nanopowder, 3g of polyimide fiber, 2g of alkylcyclohexylbromobenzene and 1g of 4-n-pentyl-4'-cyanobiphenyl, mix and grind And sieve 900 mesh, obtain mixture 3;

[0023] In the fourth step, add 12 g of ethyl ethoxy propionate to the mixture 2, mixture 3, 0.2 g of defoamer, 3 g of dispersant and 0.3 g of leveling agent obtained in the third step, mix evenly and stir for 60 minutes to obtain coating.

[0024] The components of the resin are: organosilicon modified epoxy resin, alkyd resin an...

Embodiment 2

[0028] Example 2 Coating 2

[0029] In the first step, mix 20 g of acrylic acid, 30 g of resin and 2 g of titanium dioxide, and stir in a stirring tank for 50 minutes to obtain a mixture 1;

[0030] In the second step, take 1 g of microcrystalline cellulose, 3 g of cellulose ether and 0.2 g of N,N-dimethylethanolamine, add the mixture 1 obtained in the first step, and continue stirring for 30 minutes to obtain a mixture 2;

[0031] In the third step, take 1g of borosilicate, 0.3g of nanopowder, 2g of polyimide fiber, 1g of alkylcyclohexylbromobenzene and 1g of 4-n-pentyl-4'-cyanobiphenyl, mix and grind And sieve 900 mesh, obtain mixture 3;

[0032] In the fourth step, add 10 g of ethyl ethoxy propionate, mix well and stir for 50 minutes to obtain coating.

[0033] Wherein, the components of the resin are: silicone-modified epoxy resin, alkyd resin and fluororesin, and the mass-to-number ratio thereof is 1:1:0.5.

[0034] Wherein, the particle size of the borosilicate is 10...

Embodiment 3

[0037] Example 3 Coating 3

[0038] In the first step, mix 30g of acrylic acid, 40g of resin and 4g of titanium dioxide, and stir in a stirring tank for 80 minutes to obtain mixture 1;

[0039] In the second step, take 2 g of microcrystalline cellulose, 5 g of cellulose ether and 0.5 g of N,N-dimethylethanolamine, add the mixture 1 obtained in the first step, and continue stirring for 40 minutes to obtain a mixture 2;

[0040] The third step is to take 2g of borosilicate, 0.8g of nanopowder, 4g of polyimide fiber, 2g of alkylcyclohexylbromobenzene and 3g of 4-n-pentyl-4'-cyanobiphenyl, mix and grind And sieve 950 mesh, obtain mixture 3;

[0041] In the fourth step, add 15 g of ethyl ethoxy propionate and mix uniformly for 100 minutes to obtain coating.

[0042] The components of the resin are: organosilicon modified epoxy resin, alkyd resin and fluororesin, and the mass-to-number ratio thereof is 2:1.5:0.8.

[0043] Wherein, the particle size of the borosilicate is 50 μm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com