Manufacturing process for uvioresistant organic silica gel

A technology of organic silica gel and manufacturing process, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as damage, and achieve the effect of prolonging aging and not easy to migrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0024] A kind of manufacturing process of anti-ultraviolet organic silica gel of the present invention, it comprises the following steps:

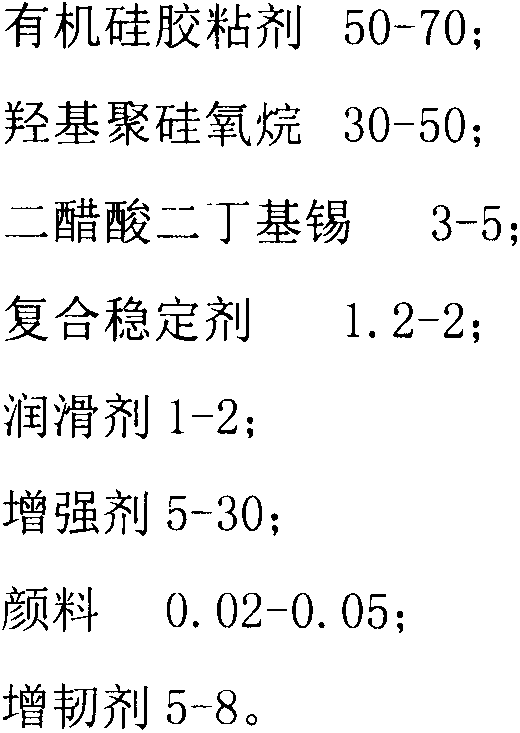

[0025] 1) Silicone adhesive, hydroxypolysiloxane, dibutyltin diacetate, composite stabilizer, lubricant, reinforcing agent 5-30, pigment 0.02-0.05, toughening agent 5-8, ultraviolet absorber 30-40, The ultraviolet absorber is a chlorinated benzotriazole ultraviolet absorber formulated into a slurry in parts by weight, which is evenly coated on the upper surface of the original silica gel layer once;

[0026] 2) Prepare the coated original silica gel layer through heat curing and light curing;

[0027] The thermal curing temperature is 80-120 degrees, and the time is 10-30s;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com