Preparation method of self-suspension proppant and prepared proppant

A technology of self-suspension and proppant, which is applied in the direction of chemical instruments and methods, earthwork drilling, and drilling compositions, etc. It can solve the problem of oil production decline, high molecular compound, drag-reducing water viscosity increase, and unfavorable flowback and other issues, to achieve the effect of reducing material cost, reducing friction, and easy flowback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

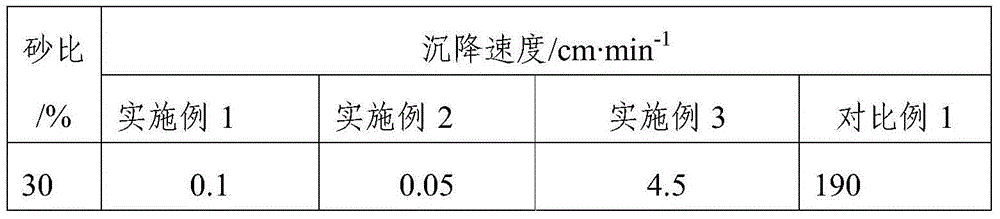

Embodiment 1

[0030] 1) Using quartz sand (river sand) as raw material, after scrubbing and drying at 120°C for 5 hours, the sand contains no water at all, and 1000g of 20-40 mesh quartz sand is screened as aggregate;

[0031] 2) Add 8g of guar gum (viscosity at room temperature: 150mPa.S) at room temperature. Stir well. After drying and cooling, sieve.

[0032] The proppant obtained after sieving has a particle size of 20-40 mesh (slightly larger than the particle size of the aggregate), and the surface of the aggregate is coated or partially coated with guar gum polymer material.

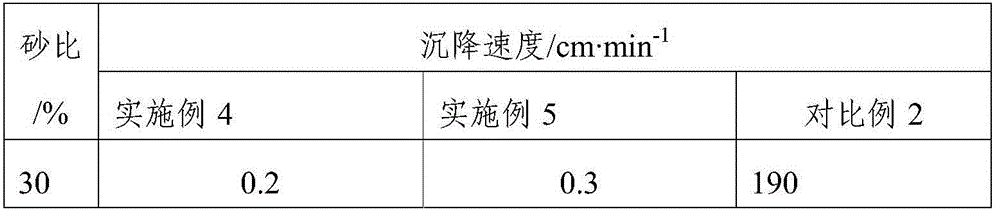

Embodiment 2

[0034] 1) Take 1kg of quartz sand (river sand) of 40-70 mesh as aggregate and set aside;

[0035] 2) Add 10g xanthan gum (viscosity 2000mPa.S at room temperature) at room temperature and mix evenly.

[0036] 3) After cooling, sieve and obtain.

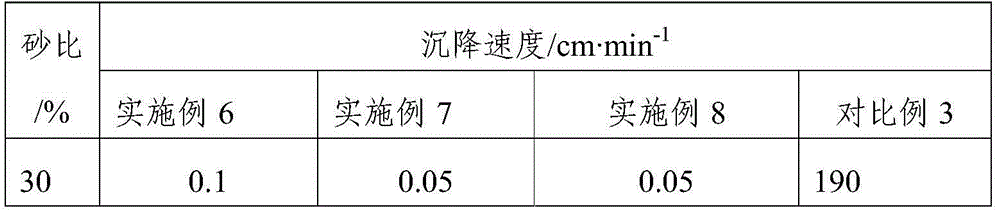

Embodiment 3

[0038] 1) Take 30-50 mesh and 1kg of quartz sand (eolian sand) as aggregate, and set aside;

[0039] 2) First heat the quartz sand to 200°C, when the temperature of the aggregate naturally drops to 130°C, prepare 5g of carboxymethyl hydroxypropyl guar gum into a 20% aqueous solution, add the aggregate and mix evenly;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com