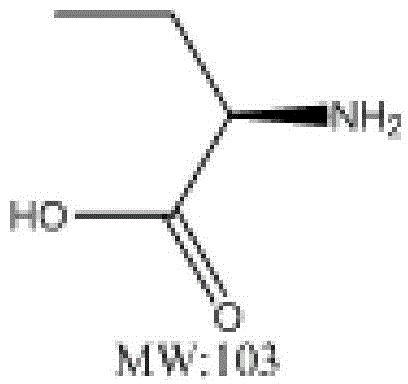

Method for preparing L-2-aminobutyric acid through biocatalysis

A technology of biocatalysis and aminobutyric acid, applied in the field of medicine and chemical industry, can solve the problems of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of method that biocatalysis prepares L-2-aminobutyric acid comprises the following steps:

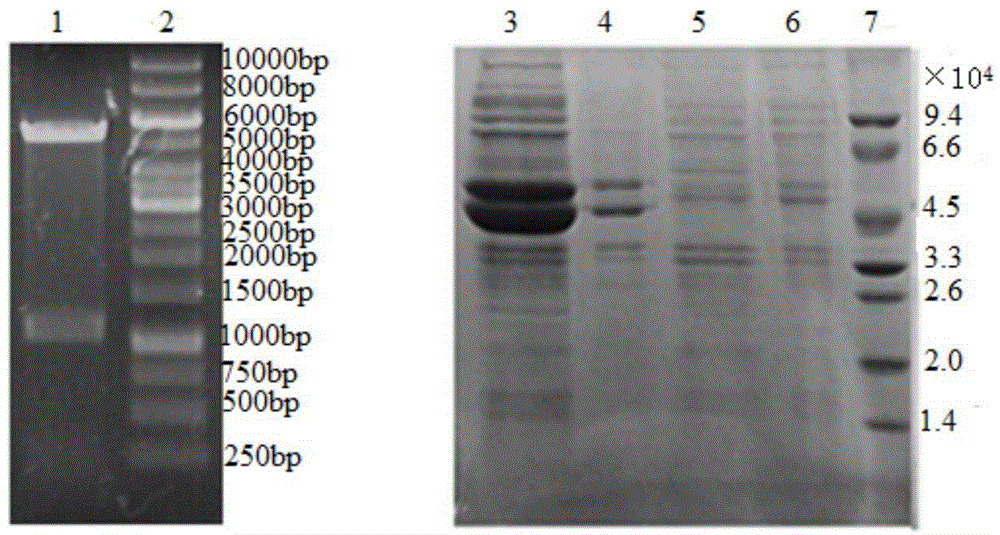

[0046] The first step, heterologous expression of formate dehydrogenase FDH and leucine dehydrogenase LDH:

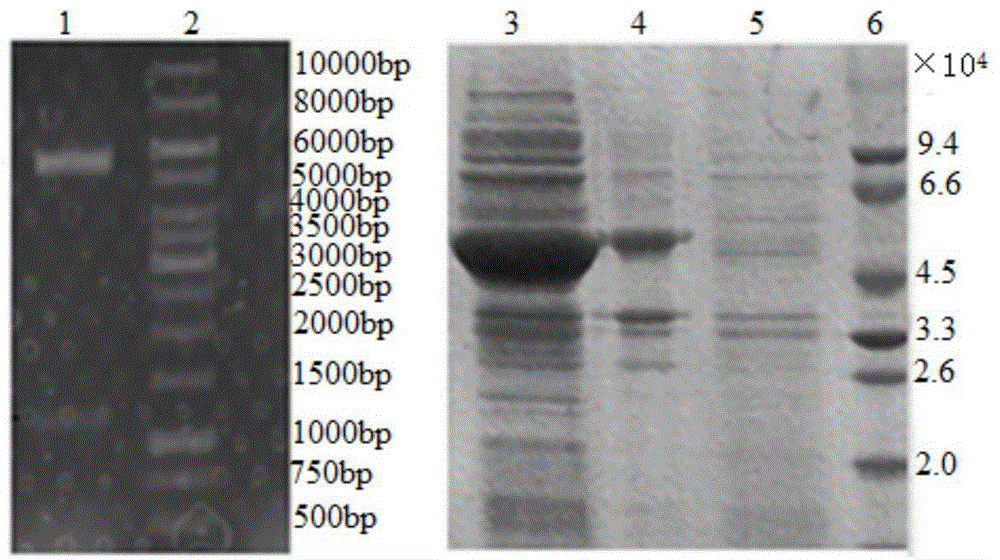

[0047] (a) Heterologous expression and activity measurement of FDH:

[0048] (1) Obtain FDH gene fragment

[0049] Primers were designed according to the gene sequence of formate dehydrogenase (FDH) (GenBank accession numbers: XM_001525495 and AAB18593) and its front and back sequences, and the better upstream primer of formate dehydrogenase (FDH) obtained after screening was 5'-AAA CATATG AAAATCGTTCTCGTTTTGTACTCC-3' (the underline is the NdeI restriction site, SEQ ID NO.: 1); the downstream primer is 5'-AAA CTCGAG TGCGACCTTTTTTGTCATTAC-3' (the underline is the XhoI restriction site, SEQ ID NO.: 2). FDH gene fragments can be efficiently obtained by amplifying with the above-mentioned upstream and downstream primers.

[0050] (2) PCR reaction system

[0051] Th...

Embodiment 2

[0076] The steps are all the same as in Example 1, except that the reaction temperature in the second step is 25°C. The yield of the product obtained was 53.5%.

Embodiment 3

[0078] The steps are all the same as in Example 1, except that the reaction temperature in the second step is 28°C. The yield of the product obtained was 65.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com