A kind of industrial-grade metal lithium refining equipment and refining method thereof

A technology for refining equipment and lithium metal, which is applied in industrial-grade lithium metal refining equipment and refining fields, can solve problems such as large safety hazards, high oil content in products, and poor separation effect, and achieves simple operation, simple equipment structure, and production and operation. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

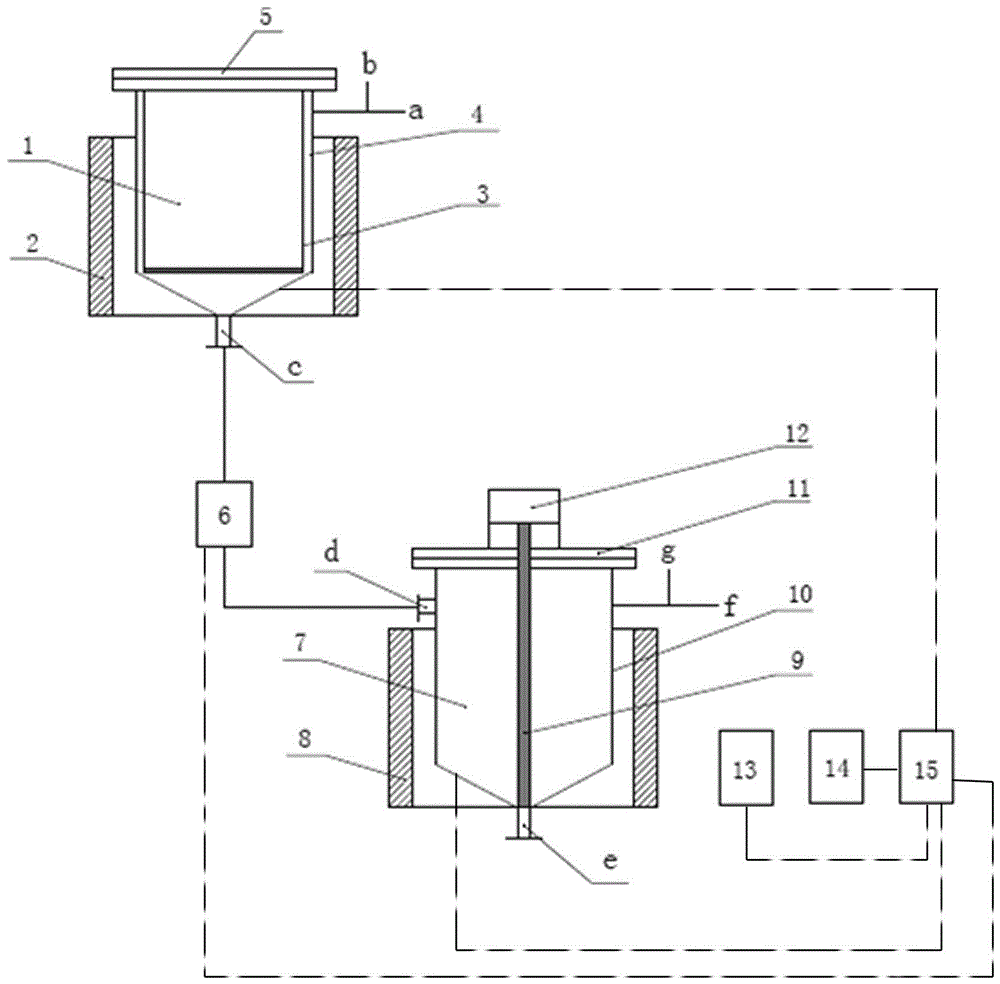

[0048] 1) Open the lid 5 of the lithium melting tank while the lithium melting tank 1 is filled with argon gas and keep the argon gas flowing continuously. Weigh 50Kg of industrial grade crude lithium and add it to the lithium melting tank 1, close the lid 5 of the lithium melting tank, and at the same time close the argon pipe b valve of the lithium melting tank to stop the flow of argon.

[0049] 2) Operate according to other steps of the refining method to obtain qualified high-sodium grade (98%) lithium metal products.

example 2

[0051] 1) Open the lid 5 of the lithium melting tank while the lithium melting tank 1 is filled with argon gas and keep the argon gas flowing continuously. Weigh 50Kg of industrial grade crude lithium and add it to the lithium melting tank 1, close the lid 5 of the lithium melting tank, and at the same time close the argon pipe b valve of the lithium melting tank to stop the flow of argon.

[0052] 2) Operate according to other steps of the refining method to obtain qualified industrial grade (99%) metal lithium products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com