Quenched and tempered state HIC (Hydrogen Induce Crack)-resistant and SSC (Sulfide Stress Cracking)-resistant wide and thick plate and preparation method thereof

A wide and thick plate, quenching and tempering technology, applied in the field of quenched and tempered anti-HIC, SSC wide and thick plate and its preparation, can solve problems such as deterioration and change, and achieve the effect of improved corrosion resistance, uniform structure and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

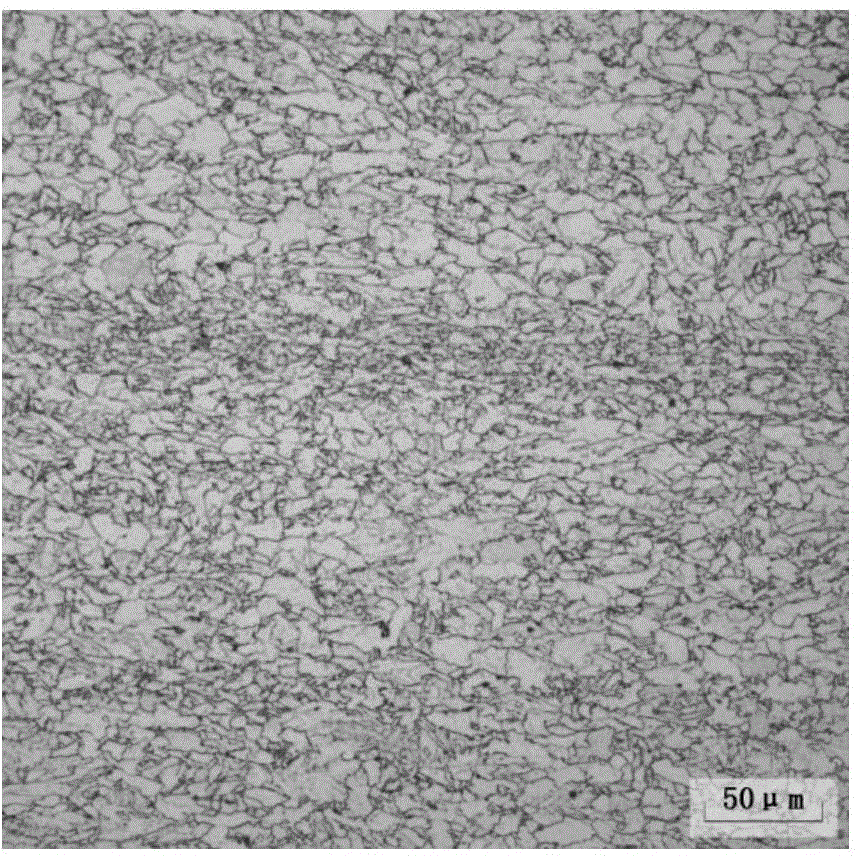

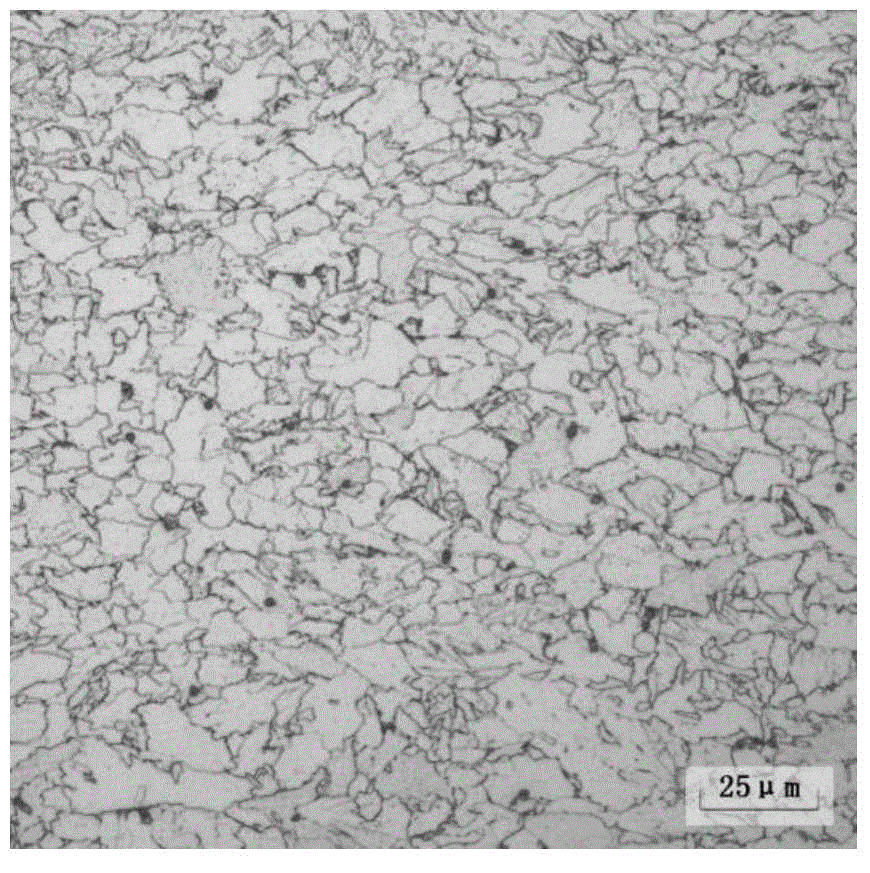

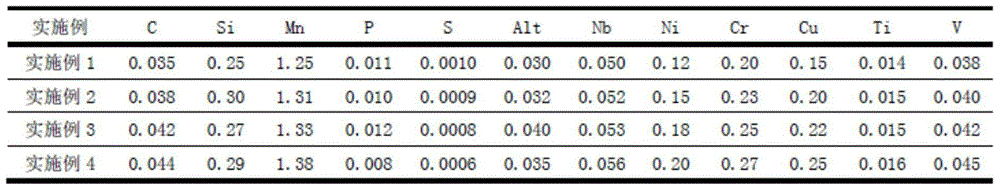

Embodiment 1

[0036] The chemical composition (wt%) is shown in Table 1, and N: ≤0.006%, H: ≤0.00015%, Ca: ≤0.004%, Ca / s: ≥2.0. The thickness of the continuous casting slab is 300mm, the thickness of the steel plate is 12.5mm, the continuous casting light reduction rate is 3%, the pouring temperature of the tundish is 1550°C, and the casting speed of the slab is 0.85m / min. The slab heating temperature is 1190°C. The starting temperature of ordinary rolling is 1150°C, and the single-pass reduction rate is 12-23%; the rolling temperature in the non-recrystallized area is 50mm thick, the starting temperature after controlled rolling is 910°C, and the final rolling temperature is 825°C. The steel plate is immersed in water to accelerate cooling, the final cooling temperature is 650°C, and the cooling rate is 15°C / s. The quenching temperature of the steel plate is 950°C, the holding time is 20min, and the water cooling rate is 38°C / s; the tempering temperature is 550°C, the holding time is 35mi...

Embodiment 2

[0038]The chemical composition (wt%) is shown in Table 1, and N: ≤0.006%, H: ≤0.00015%, Ca: ≤0.004%, Ca / s: ≥2.0. The thickness of the continuous casting slab is 300mm, the thickness of the steel plate is 14.3mm, the continuous casting light reduction rate is 4%, the pouring temperature of the tundish is 1540°C, and the casting speed of the slab is 0.80m / min. The slab heating temperature is 1180°C. The starting temperature of ordinary rolling is 1120°C, and the single-pass reduction rate is 13-25%; the temperature-controlled thickness of rolling in the non-recrystallized area is 57mm, the starting rolling temperature after controlled rolling is 900°C, and the final rolling temperature is 815°C. The steel plate is immersed in water to accelerate cooling, the final cooling temperature is 620°C, and the cooling rate is 13°C / s. The quenching temperature of the steel plate is 930°C, the holding time is 25min, and the water cooling rate is 35°C / s; the tempering temperature is 530°C,...

Embodiment 3

[0040] The chemical composition (wt%) is shown in Table 1, and N: ≤0.006%, H: ≤0.00015%, Ca: ≤0.004%, Ca / s: ≥2.0. The thickness of the continuous casting slab is 300mm, the thickness of the steel plate is 17.5mm, the continuous casting light reduction rate is 4.5%, the pouring temperature of the tundish is 1535°C, and the casting speed of the slab is 0.75m / min. The slab heating temperature is 1170°C. The starting temperature of ordinary rolling is 1115°C, and the reduction rate of a single pass is 15-28%; the rolling temperature control thickness in the non-recrystallized area is 65mm, the starting rolling temperature after controlled rolling is 885°C, and the final rolling temperature is 805°C. The steel plate is immersed in water to accelerate cooling, the final cooling temperature is 580°C, and the cooling rate is 12°C / s. The quenching temperature of the steel plate is 920°C, the holding time is 32min, and the water cooling rate is 32°C / s; the tempering temperature is 500°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com