Optical fiber current sensor based on ring cavity ring-down spectroscopy technology

A technology of ring-down spectroscopy and fiber optic current, applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems that the accuracy and stability of current measurement cannot be determined or not considered, and achieve easy process manufacturing, overcoming The effect of excessive loss and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific structure, principle and structural optimization process of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

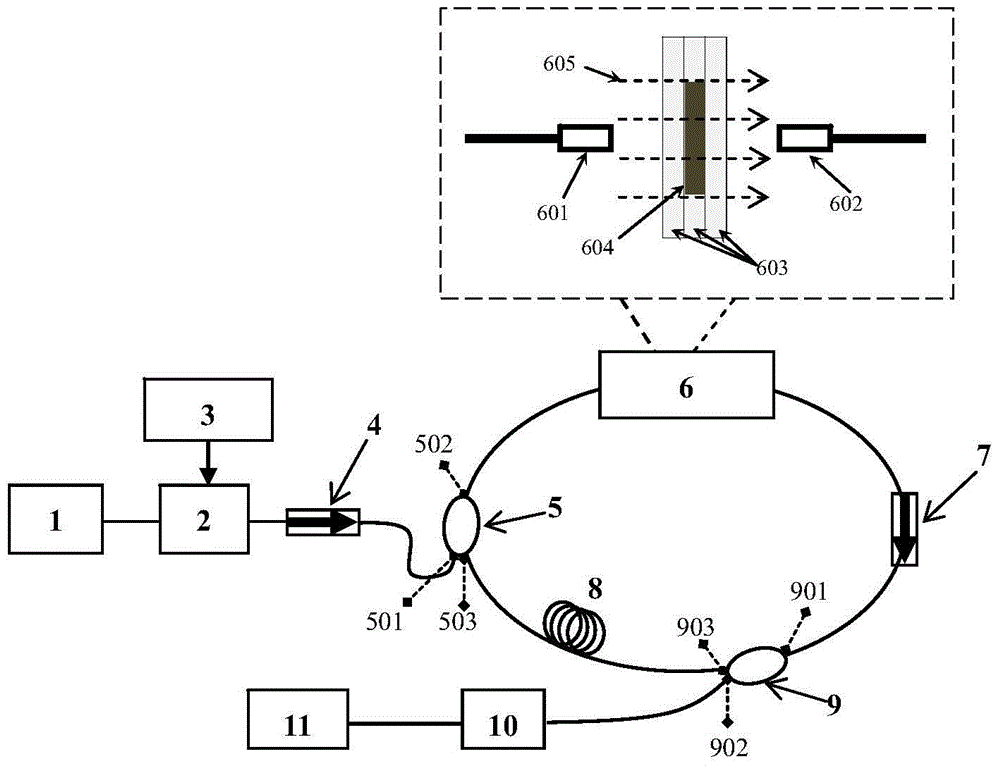

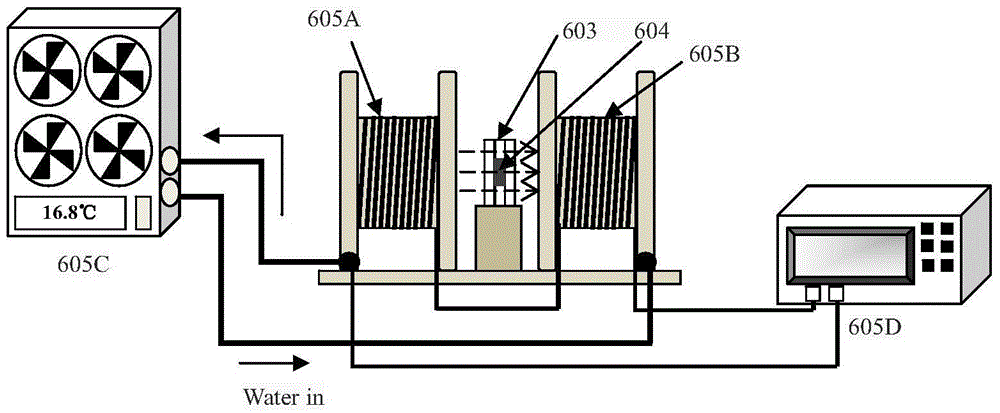

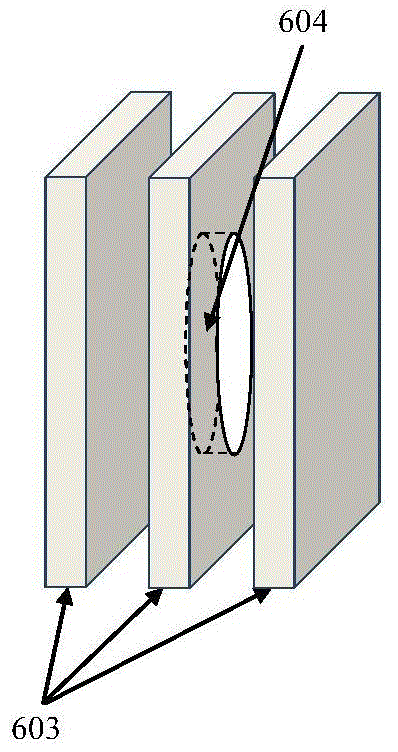

[0026] The present invention proposes a fiber optic current sensor based on ring cavity ring-down spectroscopy technology and magnetic fluid. The sensor consists of a tunable laser 1, an electro-optical modulator 2, a waveform generator 3, a No. 1 optical isolator 4, and a No. 2 × 2 A coupler 5, a current sensing unit 6, a No. 2 optical isolator 7, a delay single-mode fiber 8, a No. 2 2×2 coupler 9, a high-speed photodetector 10 and a spectrometer 11. The No. 1 2×2 coupler 5, the current sensing unit 6, the No. 2 optical isolator 7, the delay single-mode fiber 8, and the No. 2 2×2 coupler 9 form a ring cavity; The spectrum light source enters the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com