Preparation method of tricobalt tetroxide-tin disulfide nanocomposite

A technology of tricobalt tetroxide and nanocomposites, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of cheap raw materials, simple preparation process, and reducing the influence of uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

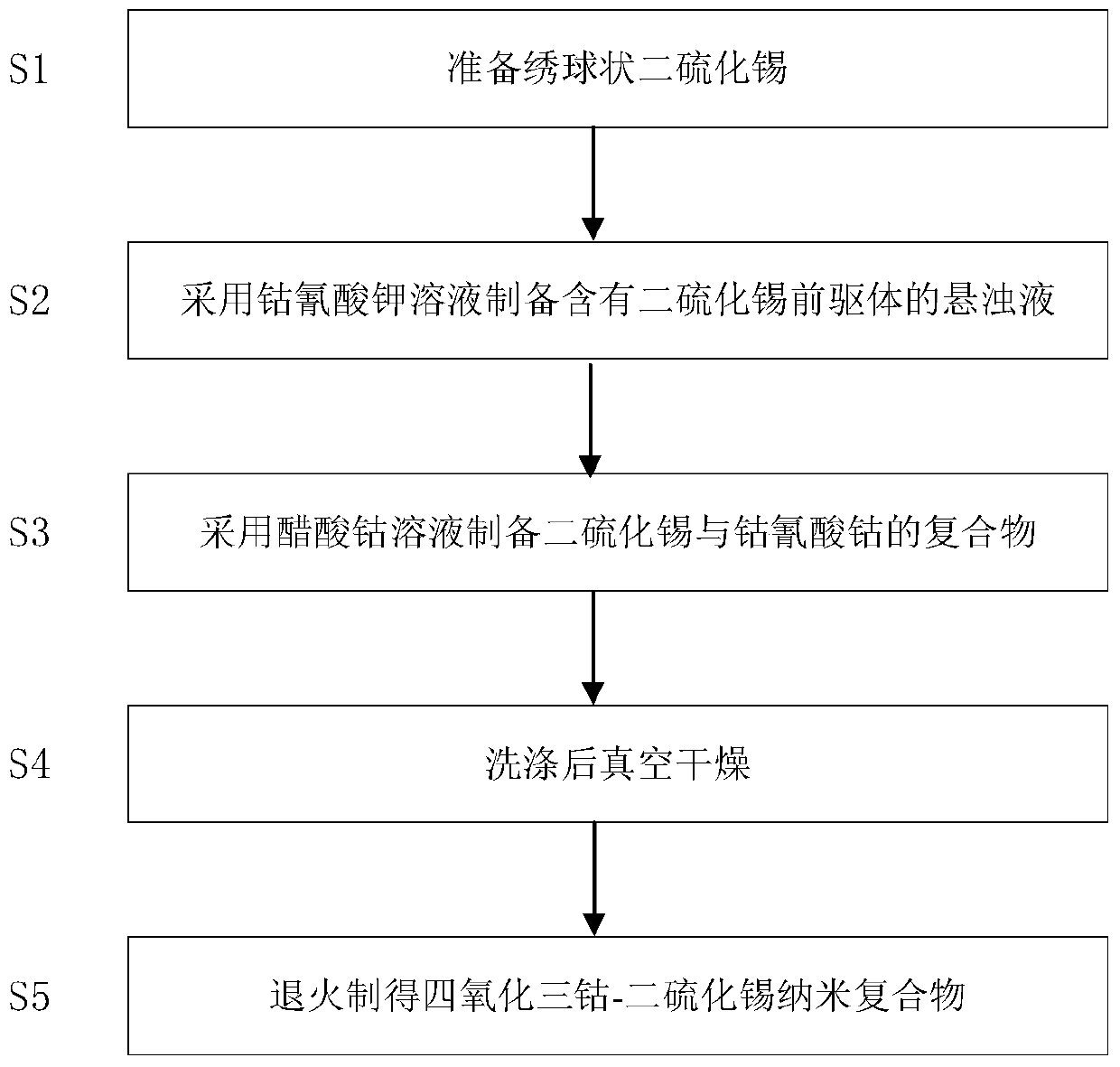

[0036] Please refer to figure 1 and figure 2 , according to a non-limiting embodiment of the present invention, provides a kind of tricobalt tetroxide-tin disulfide (Co 3 o 4 / SnS 2 ) A method for preparing a nanocomposite, the method comprising the following steps.

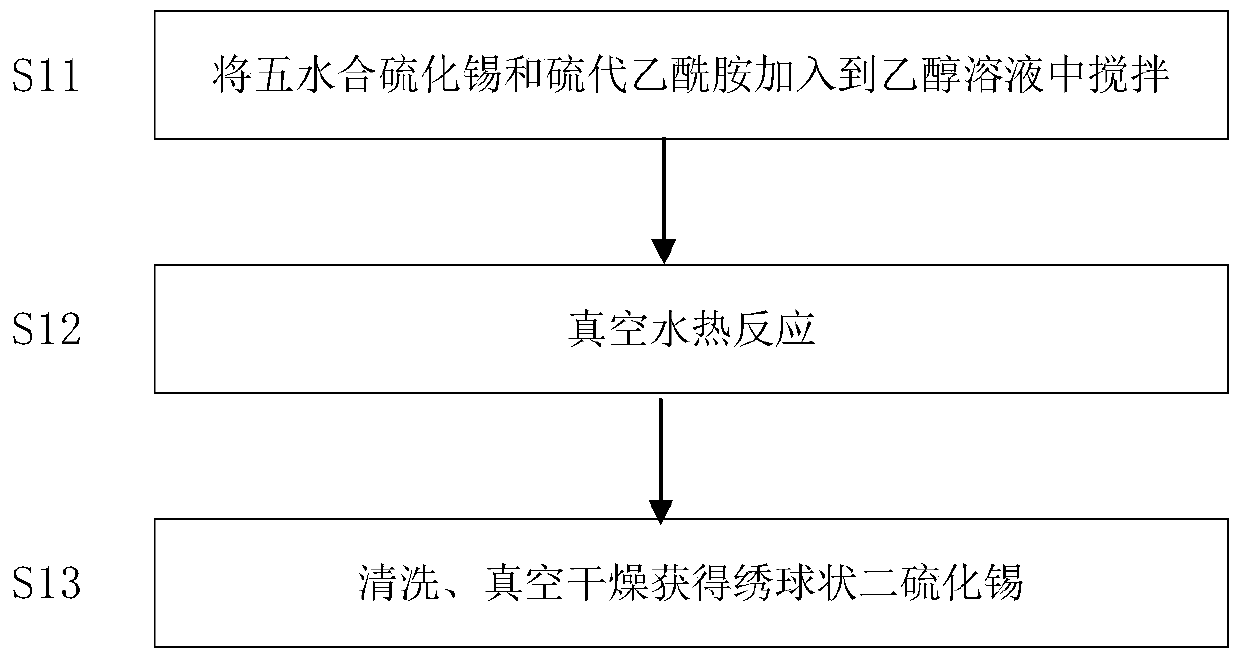

[0037] Prepare hydrangea-shaped tin disulfide, this step specifically includes: adding tin sulfide pentahydrate and thioacetamide to 99% volume ethanol solution in a mass ratio of about 1:1:100, and stirring magnetically for about 4 hours to obtain a clear solution; The clarified solution is subjected to vacuum hydrothermal reaction, the hydrothermal reaction temperature is about 170 degrees Celsius, the reaction time is about 13 hours, and naturally cooled after the reaction; and, the hydrothermal reaction product is washed with 99% volume ethanol solution and deionized water successively To a pH value of about 6, vacuum-dried for about 10 hours to obtain hydrangea-shaped tin disulfide.

[0038] Disperse t...

Embodiment 1

[0045] A preparation method of tricobalt tetroxide-tin disulfide nanocomposite, such as figure 1 and figure 2 As shown, the following steps S1-S5 are included.

[0046] In step S1, hydrangea-shaped tin disulfide is prepared, specifically including steps S11-S13.

[0047] In step S11, about 1.5 g of tin sulfide pentahydrate and thioacetamide with a mass ratio of 1:1 were added into about 150 ml of 99% volume ethanol solution, and magnetically stirred for 3 h.

[0048] In step S12, move the clarified solution into a 200ml hydrothermal reaction kettle, put it into a vacuum drying oven for hydrothermal reaction, the hydrothermal reaction temperature is 160°C, and the reaction time is 12h. After the reaction, the oven is naturally cooled.

[0049] In step S13, wash with 99% volume ethanol solution and deionized water until the pH value is 7, and dry in vacuum for 12 hours for later use.

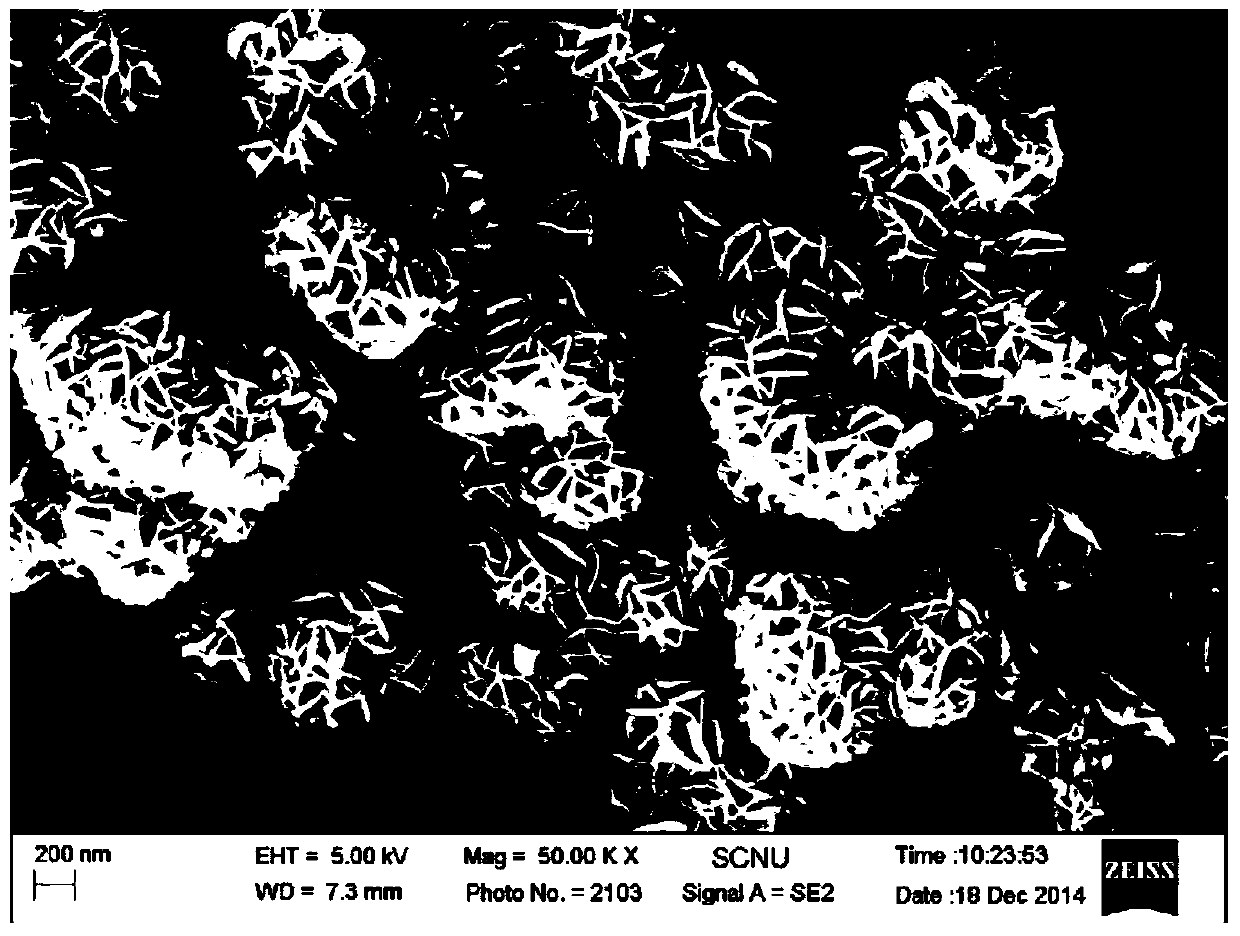

[0050] Please refer to image 3 with Figure 4 , the SEM image (scanning electron microg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com