Microemulsion containing emamectin benzoate and lufenuron

A technology of emamectin and benzoate, which is applied in the direction of insecticides, biocides, animal repellants, etc., can solve the problems of not being disclosed, achieve low cost, delay the emergence of drug-resistant individuals, and prevent and control Various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

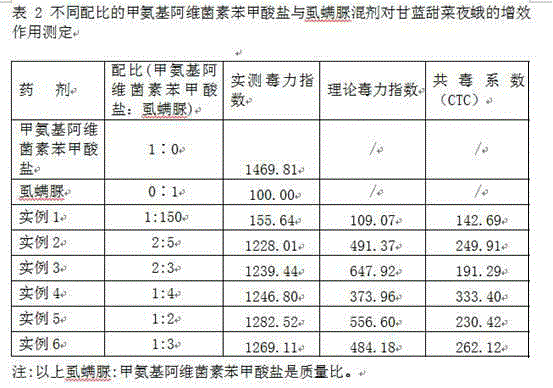

Method used

Image

Examples

Embodiment 1

[0031] The microemulsion containing emamectin benzoate and lufenuron comprises the following components by weight percentage:

[0032] Emamectin benzoate: 0.2%;

[0033] Lufenuron: 30%;

[0034] Solvent: 10%;

[0035] L-α-terpineol: 5%;

[0036] Surfactant: 10%;

[0037] Synergist: 1%;

[0038] Water: Make up to 100%.

[0039] Described solvent is the mixture of the methyl alcohol of 2% by weight and the sec-butyl ester of 8% by weight; 3% NP-10 mixture; the synergist is silicone; the water is tap water.

[0040] The preparation method of the pesticide microemulsion containing emamectin benzoate and lufenuron is as follows: weigh emamectin benzoate, lufenuron, methanol and sec-butyl ester, L-α-terpineol, surfactant styrylphenyl polyoxyethylene ether, NP-10 and organic silicon, put the above raw materials into the reaction kettle according to the conventional method of preparing microemulsion and mix them, add water to make up to 100 % sti...

Embodiment 2

[0042] The microemulsion containing emamectin benzoate and lufenuron comprises the following components by weight percentage:

[0043] Emamectin benzoate: 0.2%;

[0044] Lufenuron: 0.5%;

[0045] Solvent: 8%;

[0046] L-α-terpineol: 5%;

[0047] Surfactant: 3%;

[0048] Synergist: 10%;

[0049] Water: Make up to 100%.

[0050] The solvent is cyclohexanone; the surfactant is NP-6; the synergist is JFC; the water is tap water.

[0051] The preparation method of the microemulsion containing emamectin benzoate and lufenuron is as follows: weigh emamectin benzoate, lufenuron, cyclohexanone, NP -6 and JFC, L-α-terpineol, the above raw materials are put into the reaction kettle according to the conventional method of preparing microemulsions and mixed, add water to make up 100% and stir evenly, and the sampling inspection is qualified to obtain the methylamino-containing product of the present invention. Microemulsion of Abamectin Benzoate and Lufenuron.

Embodiment 3

[0053] The microemulsion containing emamectin benzoate and lufenuron comprises the following components by weight percentage:

[0054] Emamectin benzoate: 2%;

[0055] Lufenuron: 3%;

[0056] Solvent: 12%;

[0057] L-α-terpineol: 3%;

[0058] Surfactant: 8%;

[0059] Synergist: 5%;

[0060] Water: Make up to 100%.

[0061] Described solvent is acetone; Described tensio-active agent is the mixture that weight percentage is 3% OP-10 and weight percentage is 5% calcium lauryl sulfate; Described synergist is fast T; The water mentioned is tap water.

[0062] The preparation method of the microemulsion containing emamectin benzoate and lufenuron is as follows: weigh emamectin benzoate, lufenuron, acetone, L-α- Terpineol, OP-10, calcium lauryl sulfate and fast T, put the above raw materials into the reaction kettle according to the conventional method of preparing microemulsions, mix them, add water to make up to 100%, stir evenly, and the sampling inspection is q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com