Columnar towel gourd vegetable sponge compression processing method as well as sheets and mattress processed by utilizing same

A technology of compression treatment and loofah, which is applied in mattresses, mechanical treatment, fiber treatment, etc., can solve the problems of loofah loss, damaged structure, improper processing methods, etc., to ensure health, good air permeability and moisture dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A columnar loofah compress processing method, carried out as follows:

[0060] (1) First choose a density of 19Kg / m 3 -30Kg / m 3 The loofah is raw material (the natural mature loofah purchased or purchased in the market), washed and dried, and the water content is controlled within 7%;

[0061] (2) cut off two ends of the dried loofah, cut into columnar loofah with a height of 3.5cm-5cm, height error ± 0.2cm, and remove seeds;

[0062] (3) The columnar loofah is sorted by diameter, 1cm is a diameter difference, and the diameter fraction is divided into 5cm-6cm, 6cm-7cm, 7cm-8cm, 8cm-9cm;

[0063] (4) the columnar loofah of each diameter class utilizes wind force to further sort by density, and the columnar loofah of each diameter class is divided into low density again (being 19Kg / m 3 -22Kg / m 3 ), medium density (23Kg / m 3 -26Kg / m 3 ), high density (27Kg / m 3 -30Kg / m 3 ) three categories, and carry out density classification sampling inspection to the sorted column...

Embodiment 2

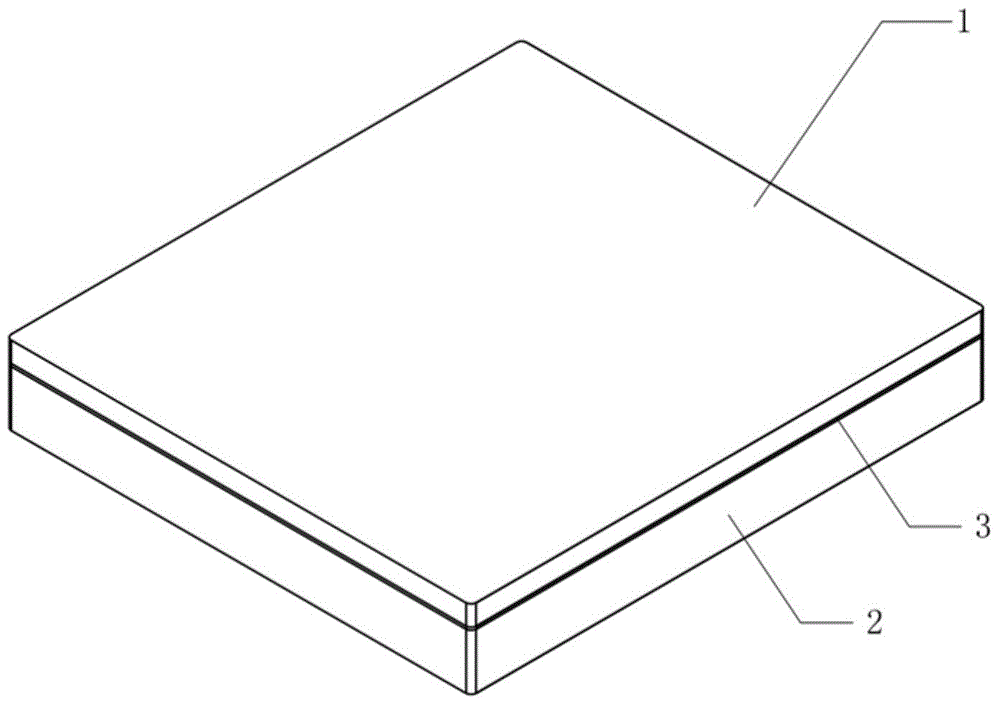

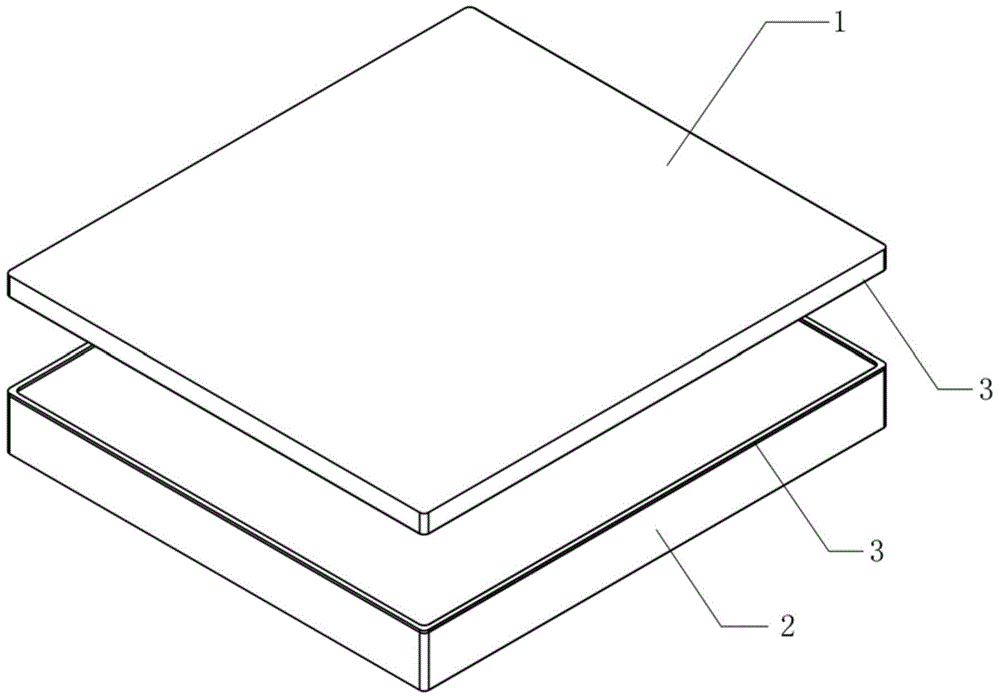

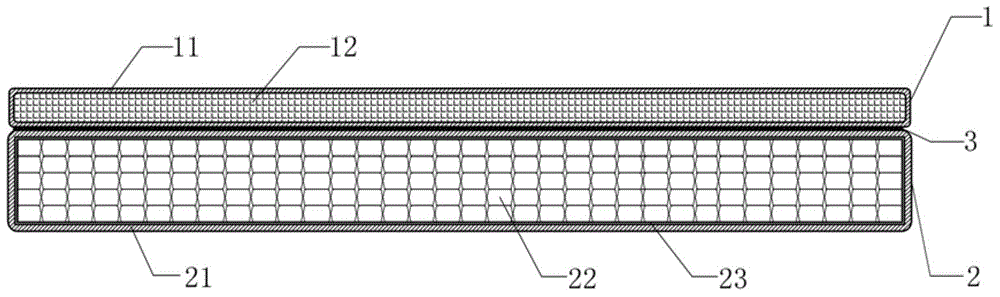

[0076] A kind of method that utilizes post-compressed columnar loofah processing sheet as described above, proceeds as follows:

[0077] (1) First, put the upper and lower pieces of non-woven fabric together and quilt them along the width direction. The quilting lines are parallel to each other and the adjacent distance is the largest diameter of the loofah D+2.5cm;

[0078] Format size of non-woven fabric:

[0079] Length (cm) = mattress core liner length + 2.5n;

[0080] Among them, n refers to the number of rows of loofah, and 2.5n means that each row needs to be increased by 2.5cm to form the cavity of each row;

[0081] n = length of mattress core liner / maximum diameter of loofah D, when n is not an integer, take the integer plus 1.

[0082] Width (cm) = mattress core width + 3cm;

[0083] (2) Select the compressed columnar loofah, and fill each filling cavity formed by the quilting line with compressed columnar loofah with corresponding density, diameter level, and co...

Embodiment 3

[0086] A kind of method that utilizes post-compressed columnar loofah processing sheet as described above, proceeds as follows:

[0087] (1) First, the two sides of the upper and lower non-woven fabrics in the width direction are sewed together;

[0088] (2) quilting corresponding zipper tapes on the upper and lower non-woven fabrics along the width direction, the zipper tapes are parallel to each other and the distance between adjacent zipper tapes is the maximum diameter of the columnar loofah D+2cm;

[0089] Format size of non-woven fabric:

[0090] Length (cm) = mattress core liner length + 2.5n;

[0091] Among them, n refers to the number of rows of loofah, and 2.5n means that each row needs to be increased by 2.5cm to form the cavity of each row;

[0092] n = length of mattress core liner / maximum diameter of loofah D, when n is not an integer, take the integer plus 1.

[0093] Width (cm) = mattress core width + 3cm;

[0094] (3) Select the compressed columnar loofah,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com