A welding equipment suitable for multi-layer and multi-pass welding of the inner wall of oil pipeline

A multi-layer multi-pass welding and welding equipment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of arc disturbance, guarantee, damage to the base, etc. effect, effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the protection scope of the present invention.

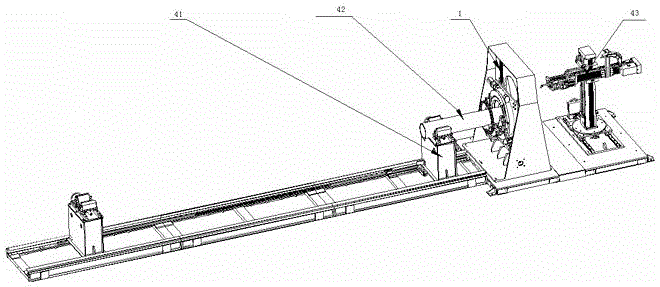

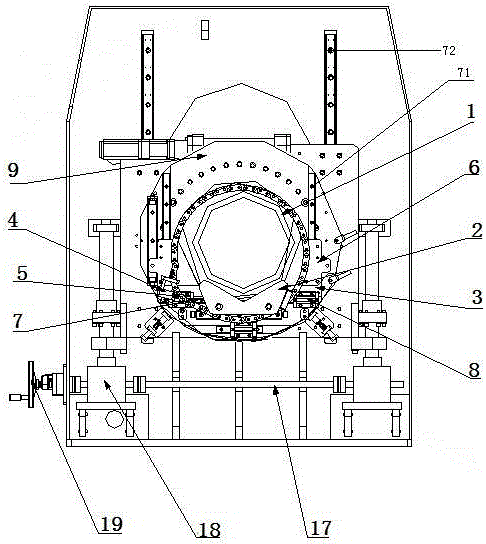

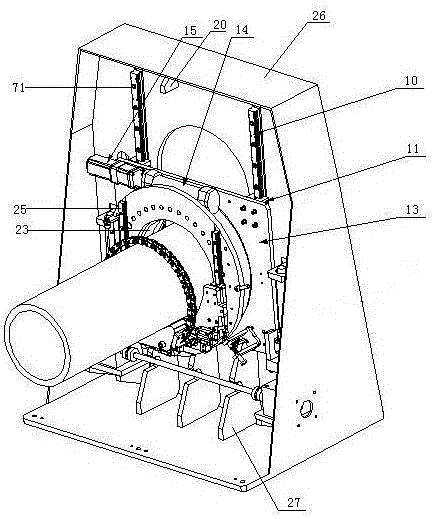

[0028] like Figure 1~6 As shown, the welding equipment of the present invention sequentially includes a support conveying assembly 41, a central control rotating assembly 42 and a welding tracking assembly 43;

[0029] The support conveying assembly 41 comprises a plurality of bases 44 arranged side by side and a guide rail 70 positioned at the bottom of the base 44, each base 44 is provided with a transmission that enables the base 44 to move on the guide rail 70, and the transmission includes a motor, and a motor drive The connected gear and the rack connected with the gear transmission, the movement of the base 44 on the guide rail 70 is realized by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com