Agent vacuum pre-compression method for treating engineering waste slurry

A technology of vacuum preloading and chemicals, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of high treatment costs, easy clogging, and low treatment efficiency. problems, to achieve the effect of large processing capacity, pollution reduction and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

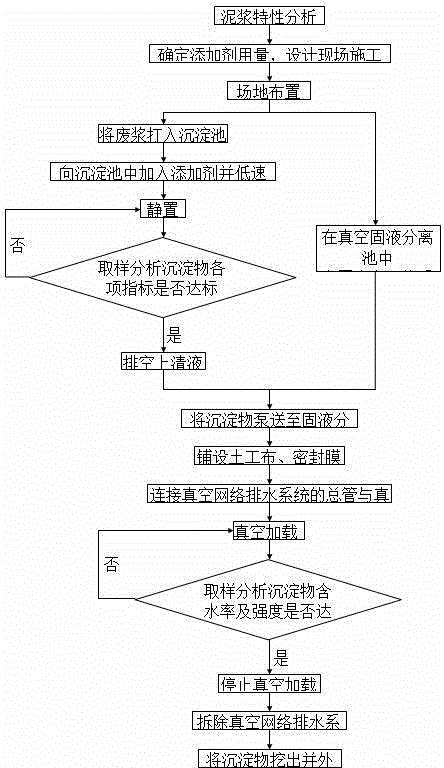

[0037] figure 1 Be the process flow diagram of the present invention's processing mud, its main steps are as follows:

[0038](1) Take engineering waste slurry samples on site, and measure and analyze their special physical and chemical properties such as moisture content, particle composition, mineral composition, PH value, and specific gravity.

[0039] (2) According to the analysis results of step (1), determine the addition amount and proportion of chemical agents A and B. The mixing ratios of A and B are about 0.01% to 0.06% and 0.05% to 0.4% respectively.

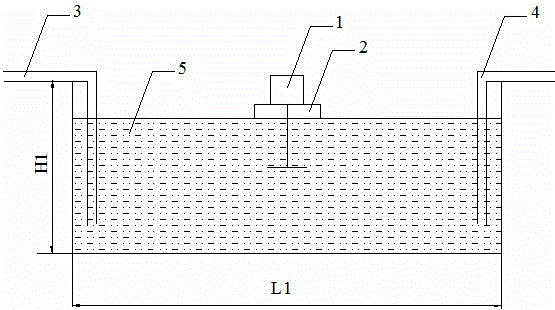

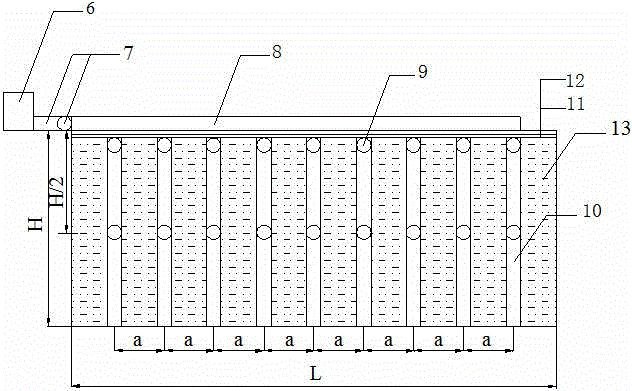

[0040] (3) Design the waste slurry sedimentation tank, vacuum solid-liquid separation tank, pumping volume, etc. according to the actual conditions of the construction site, such as the size of the site, manpower, mechanical shifts, and the amount of waste slurry to be treated, such as figure 2 ~4 is shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com