A method of coal liquefaction to produce light oil

A technology for light oil and coal, which is applied in the field of coal liquefaction and coal liquefaction to produce light oil. It can solve the problems of increasing energy consumption and hydrogen consumption, and achieve the effects of less energy and material loss, short process, and large operating flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

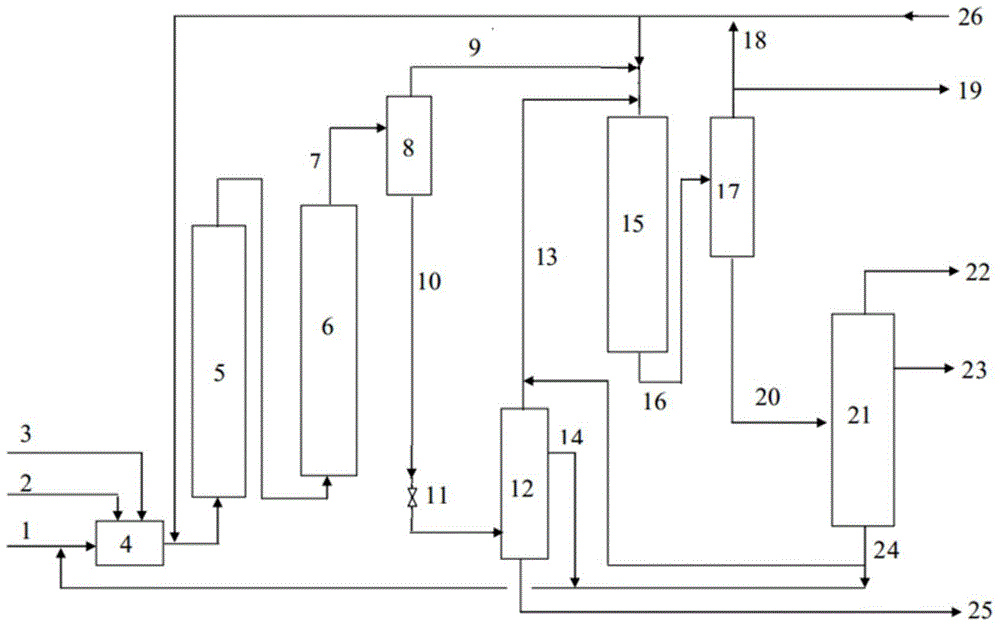

[0029] The method for producing light oil by coal liquefaction of the present invention specifically comprises the following steps:

[0030] a. Mix and stir coal powder, solvent oil and catalyst to make oil-coal slurry, and mix with H 2 Mixed into the suspension bed hydrocracking unit for hydrocracking reaction to obtain gas, liquid and solid three-phase mixed products, the operating pressure of the suspension bed reaction unit is 16-25MPa, the temperature is 440-500°C, and the gas-liquid ratio is 500-1500L / kg. The air speed is 0.2~1.5h -1. The coal powder, solvent oil and catalyst are mixed and stirred in the raw material tank, the stirring time is 2-6 hours, and the stirring temperature is 120°C-180°C. The mass content of the coal powder in the oil-coal slurry is 30-55%, the particle size is 20-200 μm, the mass content of water is not higher than 2%, and the mass content of ash is not higher than 8%. The solvent oil is composed of heavy oil, the side cut oil of the vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com