Apparatus and method for treating gas discharged from cement kiln

A technology of treatment device and cement kiln, applied in gas treatment, waste heat treatment, separation method, etc., can solve the problems of increased heavy metal concentration, high operating cost, exceeding management value, etc., achieve effective recovery, inhibit the production of organic pollutants, The effect of reducing the cost of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, embodiments of the present invention will be described with reference to the drawings.

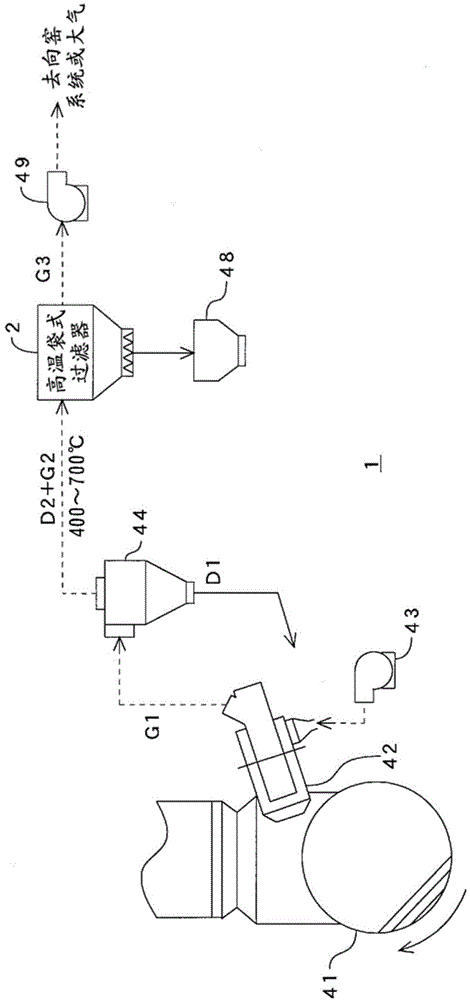

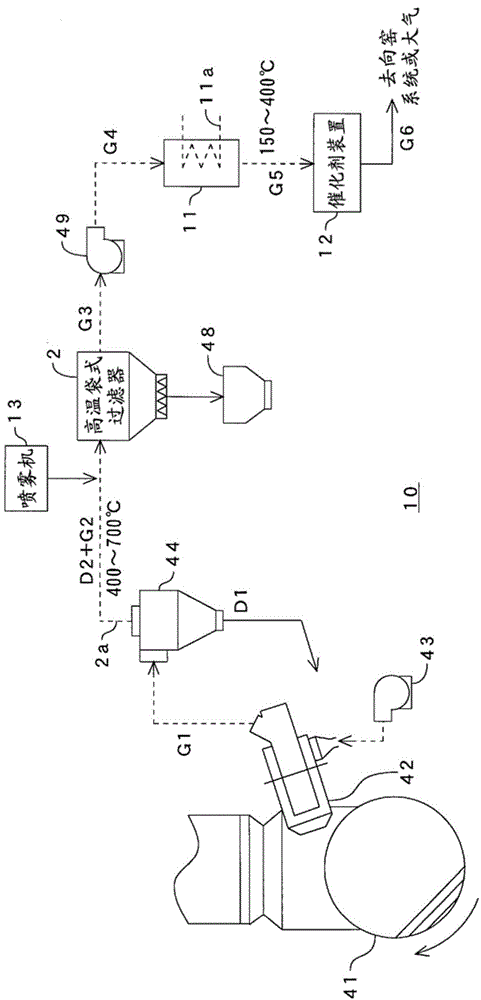

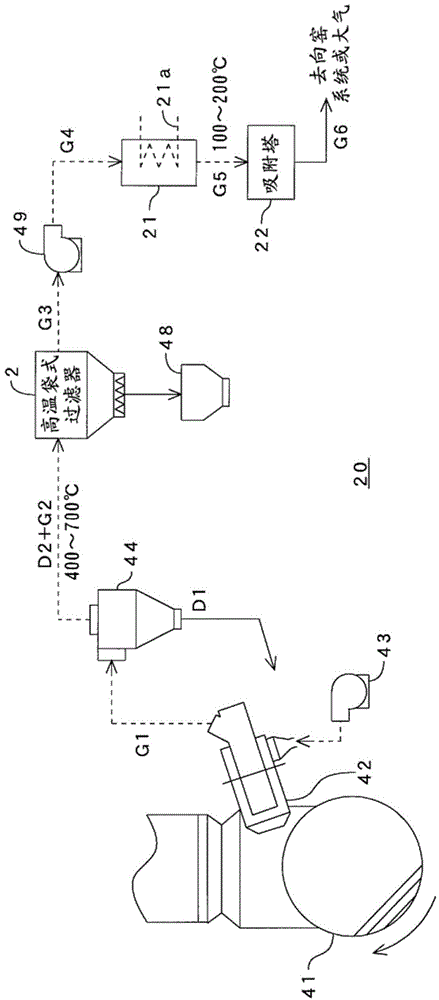

[0039] figure 1 It shows the first embodiment of the treatment device for cement kiln exhaust gas related to the present invention. The treatment device 1 is roughly composed of the kiln exhaust gas flow path from the tail end of the cement kiln 41 to the lowest stage cyclone (not shown), An extraction probe 42 for extracting part of the combustion gas, a cooling fan 43 for supplying cold air to the probe 42, and a cyclone as a classifier for separating coarse powder D1 contained in the extraction gas G1 extracted by the probe 42 Device 44, the high-temperature bag filter 2 for solid-gas separation of the exhaust gas G2 containing the fine powder D2 discharged from the cyclone 44, and the dust box 48 for recovering the fine powder (chlorine bypass dust) collected by the high-temperature bag filter 2 , an exhaust fan 49 that guides the exhaust G3 of the high-temperature bag f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com