Ion bombardment device and substrate surface cleaning method using same

An ion bombardment, substrate technology, applied in ion implantation plating, metal material coating process, vacuum evaporation plating and other directions, can solve the substrate etching amount obstruction, etching amount does not meet the etching amount, uniform evaporation obstruction And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

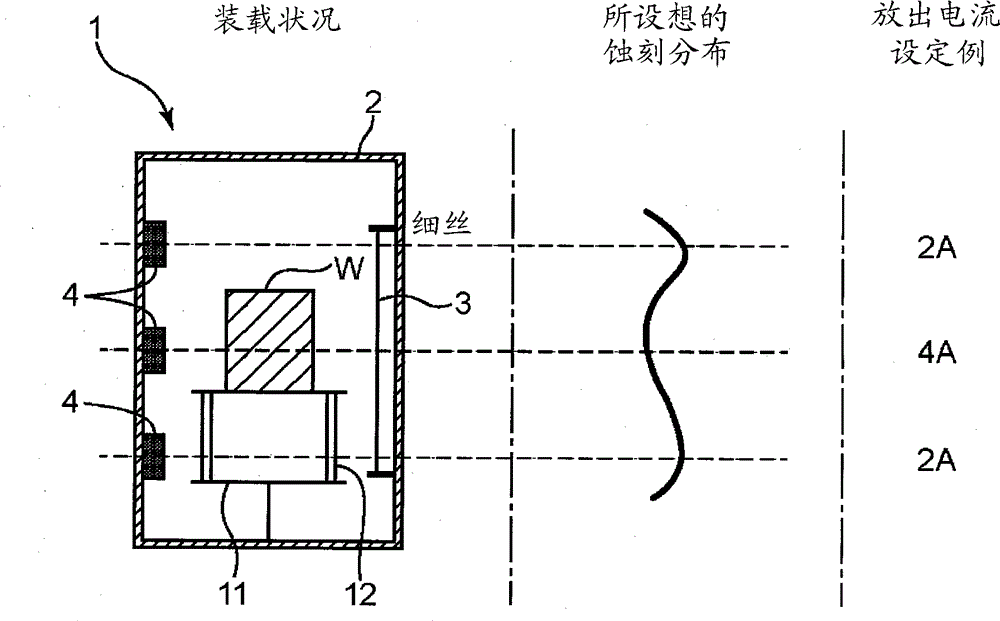

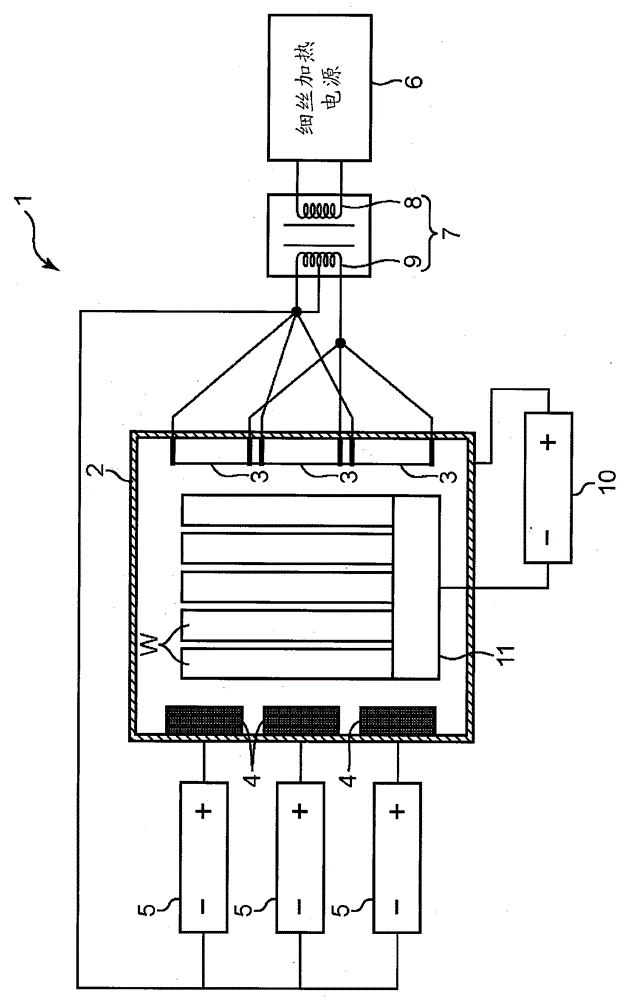

[0023] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0024] figure 1 and figure 2 The ion bombardment apparatus 1 of the first embodiment of the present invention is shown. The ion bombardment apparatus 1 is an apparatus for cleaning the surface of the substrate W before the protective film is formed by a physical vapor deposition method (PVD method) or a chemical vapor deposition method (CVD method). The ion bombardment apparatus 1 includes a vacuum chamber 2 that accommodates the substrate W, and has a function of performing the cleaning by irradiating the substrate W loaded in the vacuum chamber 2 with gas ions generated in the vacuum chamber 2 .

[0025] As the base material W to be cleaned by the ion bombardment apparatus 1, various base materials are considered, but there are, for example, cutting tools, dies used in press working, and the like. A large load is applied to these cutting tools and dies during cutting and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com