Gel type fish soup product and production process thereof

A gel-type fish soup and production process technology, applied in the field of aquatic product processing, can solve problems such as damage to the shape, hidden safety hazards, fish soup can not be invincible, etc., to achieve thick and white color, maintain the integrity of fish, and delicious taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

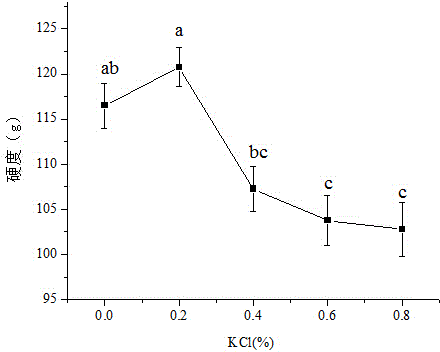

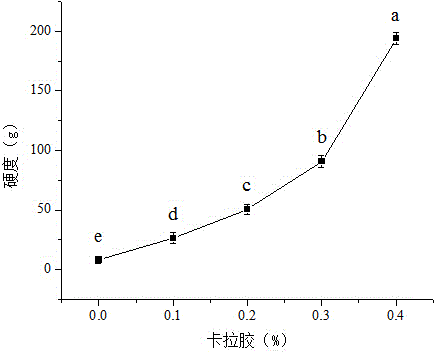

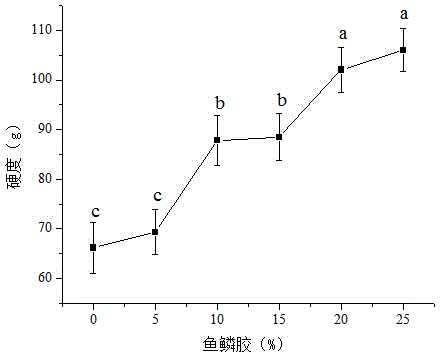

[0038] Example 1: Slaughter black fish, remove fish scales and viscera, wash it, and then soak and marinate for 12 hours in a pickling solution composed of 8wt% NaCl, ginger, green onion and cooking wine. Take out the marinated fish body, wash it and drain it, lightly pat a layer of flour on the surface, fry in oil at 120°C for 4 minutes, add 2 times the volume of distilled water at 70°C after taking it out, add ginger and green onion, The temperature of the soup liquid was boiled for 60 minutes at 90°C. In addition, wash the scraped black fish scales, add 5 times the water and cook under high pressure for 30 minutes to remove the residue, and shape the filtered glue solution at 4°C. Add 1% KCl, 2% carrageenan, 3% salt, and 30% fish scale glue to the boiled black fish soup by mass, mix evenly, and cool at 4°C to form a gel-type black fish soup.

Embodiment 2

[0039] Example 2: Slaughter crucian carp, remove fish scales and viscera, and clean it; soak it in a pickling solution composed of 3wt% NaCl, ginger, green onions and cooking wine for 10 hours; clean it and drain it, and pat the surface with a layer of flour , fry in oil at 160°C for 3 minutes; take it out, add 3 times the volume of hot distilled water at 75°C, add ginger, green onions and tofu, and boil for 45 minutes at 80°C. In addition, wash the scraped crucian carp scales, add 8 times the water and cook under high pressure for 30 minutes to remove the residue, and mold the filtered glue solution at 4°C; add 0.5% KCl, Mix 0.5% carrageenan, 15% fish scale glue, and 1% salt, and cool at 4°C to form a gel-type crucian carp soup.

Embodiment 3

[0040] Example 3: Slaughter the stickleback, remove the scales and viscera, and clean it; put it into a pickling solution consisting of 5wt% NaCl, ginger, green onions and cooking wine and soak it for 10 hours; clean it, drain it, and pat the surface for a while. Layer flour, fry in oil at 220°C for 2 minutes; take it out, add 4 times the volume of hot distilled water at 80°C, add ginger, green onions and tofu, and cook at 70°C for 80 minutes. In addition, wash the fish scales, add 7 times the water and cook under high pressure for 30 minutes to remove the residue, and shape the filtered glue solution at 4°C; add 1.5% KCl, 1.5% Mix carrageenan, 10% fish scale glue, and 1% salt, and cool at 4°C to form a gel-type fish soup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com