Copper triazole wood antiseptic agent and preparation method thereof

A technology of wood preservative and manufacturing method, which is applied in the direction of wood treatment, impregnating wood, manufacturing tools, etc., can solve the problems of affecting the anti-corrosion and insecticidal effect, the fixed amount of active ingredients is small, the solubility of triazole is small, etc. Small damage and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

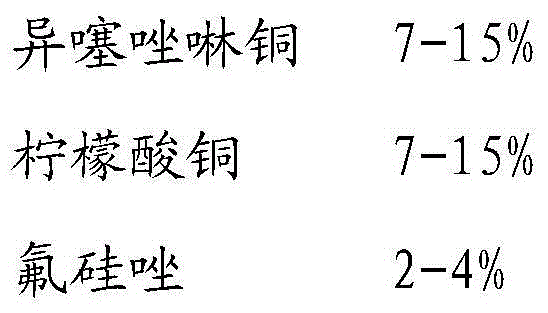

[0018] A copper triazole wood preservative, characterized in that the preservative is made of the following parts by weight of raw materials:

[0019]

[0020] The invention also provides a preparation method of the copper triazole wood preservative, which is characterized in that it comprises the following steps:

[0021] (1) Prepare raw materials according to the weight ratio;

[0022] (2) Prepare the triazole solution first: Dissolve the required amount of flusilazole, difenoconazole, and cyproconazole in isopropanol, add dodecyl dimethyl benzyl ammonium chloride and diphosphate Ammonium hydrogen to completely dissolve the triazole compound, then add imidacloprid to make a triazole solution;

[0023] (3) Preparation of copper ammonia complex: first add water to the reactor, quickly add copper isothiazoline and copper citrate, stir, then slowly add ammonia water, stir while adding, control the adding speed to prevent the reaction from violent reaction After the copper salt is compl...

Embodiment 2

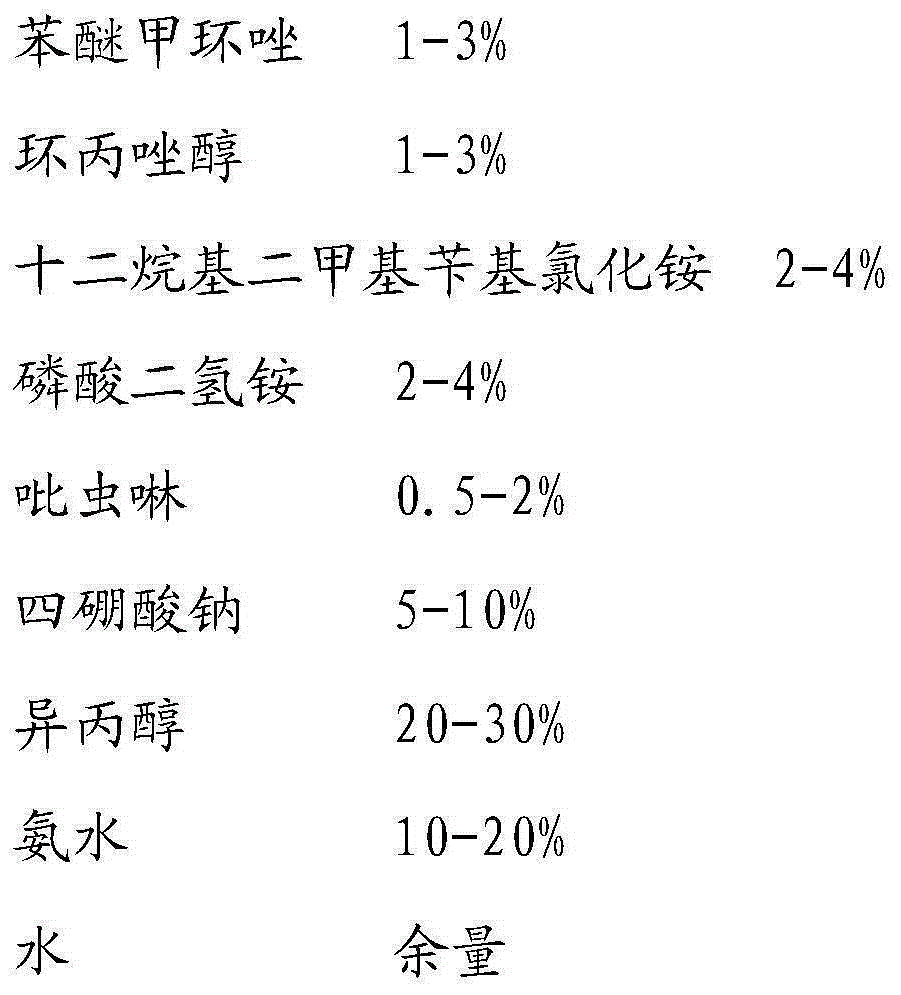

[0026] A copper triazole wood preservative, characterized in that the preservative is made of the following parts by weight of raw materials:

[0027]

[0028] The invention also provides a preparation method of the copper triazole wood preservative, which is characterized in that it comprises the following steps:

[0029] (1) Prepare raw materials according to the weight ratio;

[0030] (2) Prepare the triazole solution first: Dissolve the required amount of flusilazole, difenoconazole, and cyproconazole in isopropanol, add dodecyl dimethyl benzyl ammonium chloride and diphosphate Ammonium hydrogen to completely dissolve the triazole compound, then add imidacloprid to make a triazole solution;

[0031] (3) Preparation of copper ammonia complex: first add water to the reactor, quickly add copper isothiazoline and copper citrate, stir, then slowly add ammonia water, stir while adding, control the adding speed to prevent the reaction from violent reaction After the copper salt is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com