Heat pipe heating fluidized bed biomass and coal co-pyrolysis system

A fluidized bed and biomass technology, applied in the fields of biofuel, chemical industry, special form of dry distillation, etc., can solve the problems of large seasonal influence of biomass, low energy density of biomass, low pyrolysis temperature, etc. The effect of chemical efficiency, reduction of tar formation, and high pyrolysis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

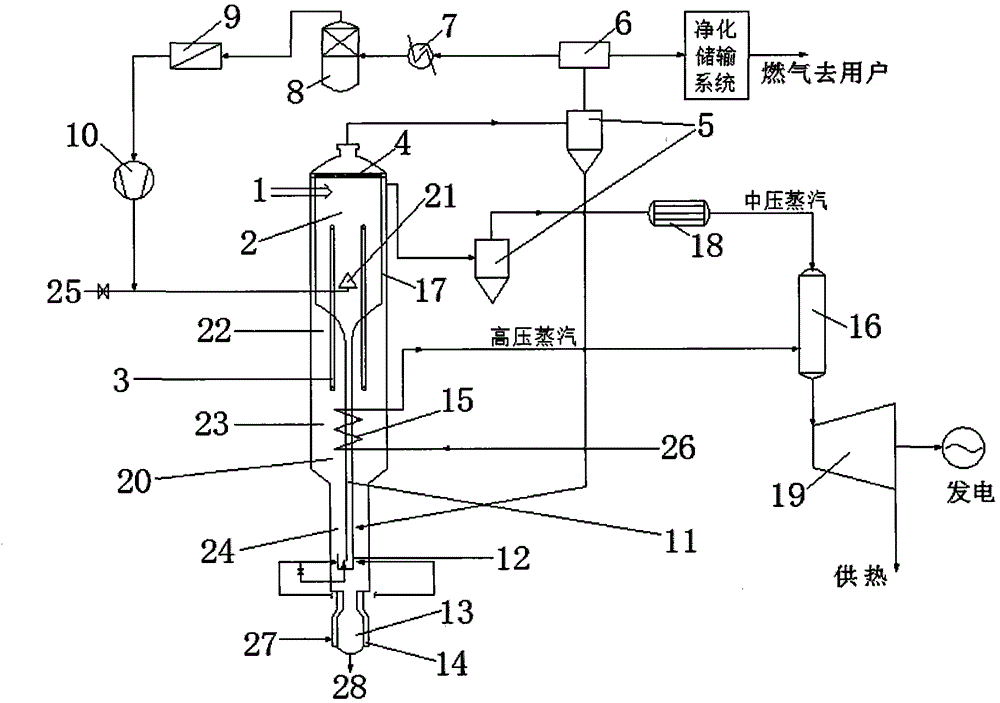

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

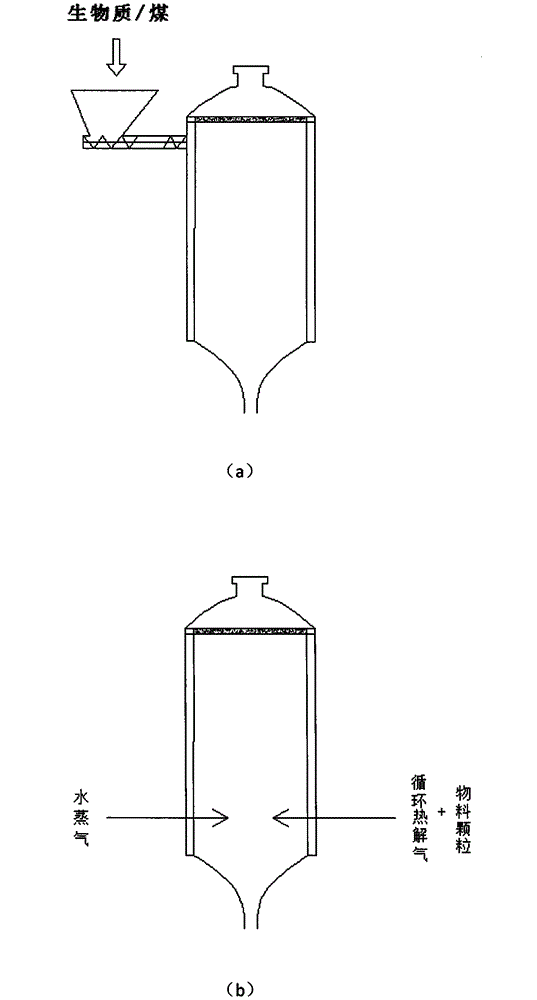

[0017] The present invention is a co-pyrolysis system of heat pipe fluidized bed biomass and coal, the upper end is a pyrolysis furnace, which includes a feed inlet 1, and the feed of the present invention has two forms (see figure 2 ), the gasification agent water vapor 25 is sprayed from the cone nozzle 21, and the pyrolysis gas passes through the filter sand layer 4, the cyclone separator 5 and the heat exchanger 6, and part of it is purified and supplied to the user, and the other part is passed through the cooler 7 and the gas-liquid separator 8. The filter 9 and the circulation compressor 10 enter the pyrolysis furnace 2 again. The lower end is the combustion furnace 20, which is divided into a flue gas section 22, a dilute-phase heat exchange section 23, and a dense-phase combustion section 24. The heat pipe 3 runs through the pyrolysis furnace 2 and the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com