Nozzle, nozzle mould and machining methods of nozzle and nozzle mould

A processing method and nozzle technology, applied in the field of 3D printing, can solve problems such as unsatisfactory requirements, and achieve the effects of high aspect ratio, high forming precision, and good processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

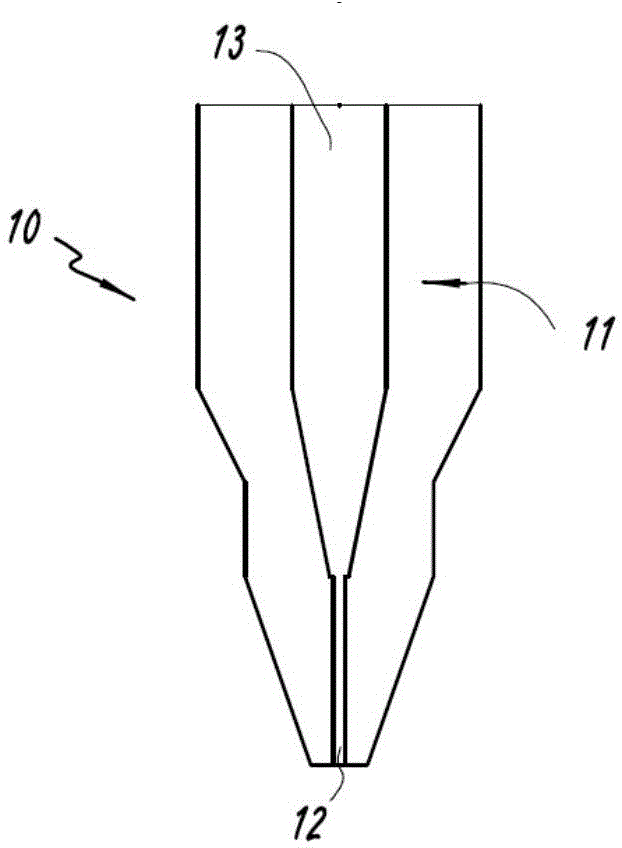

[0054] Such as figure 1 As shown, the nozzle 10 includes: a nozzle body 11 , a nozzle cavity 13 and a nozzle hole 12 . Wherein, nozzle cavity 13 can be polyhedron, cylinder or conical structure, and its top is connected with nozzle channel 12, and nozzle channel 12 is cylindrical, and can also be right cylinder, or elliptic cylinder, or paraboloid, or truncated. The head cone or multi-section structure, the centerline diameter of the nozzle hole 12 is a straight line, and can also be designed as a straight line, a curve, or even a spiral structure according to needs. The nozzle inner cavity 13 communicates with the first material sampling device. In this embodiment, the nozzle 10 is an array structure.

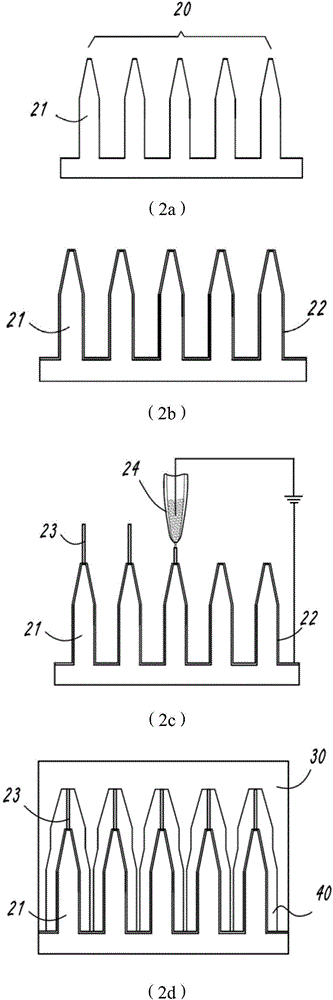

[0055] Such as figure 2 As shown, the nozzle 10 process of processing the present embodiment is as follows:

[0056] (1) figure 2 In 2a, high-strength gypsum powder, water and 801 glue are used to form a slurry with a mass fraction ratio of 50:20:3, and sulfur tires are ...

Embodiment 2

[0061] The nozzle structure of this embodiment is similar to that of Embodiment 1. Except for the structure of the inner mold 21 and the shape and size of the core, all the other structures are the same as that of Embodiment 1. The top end of the inner mold 21 of Embodiment 1 is a conical truncated cone, such as Figure 4 Shown, and the top end of the inner mold 21 of the present embodiment is conical shape, as Figure 5 shown.

[0062] Present embodiment processes this nozzle 10 processes as follows:

[0063] (1) Adopt the method of mechanical processing, select copper metal material for use, remove the excess material of corresponding position through drilling, punching, grinding and other processing processes, obtain the outer mold 30 and inner mold 21 with smooth surface, inner mold 21 has a round table the top of the shape;

[0064] (2) Fix the inner mold 21 flatly on the three-dimensional mobile platform of the three-dimensional micro-nano structure manufacturing syste...

Embodiment 3

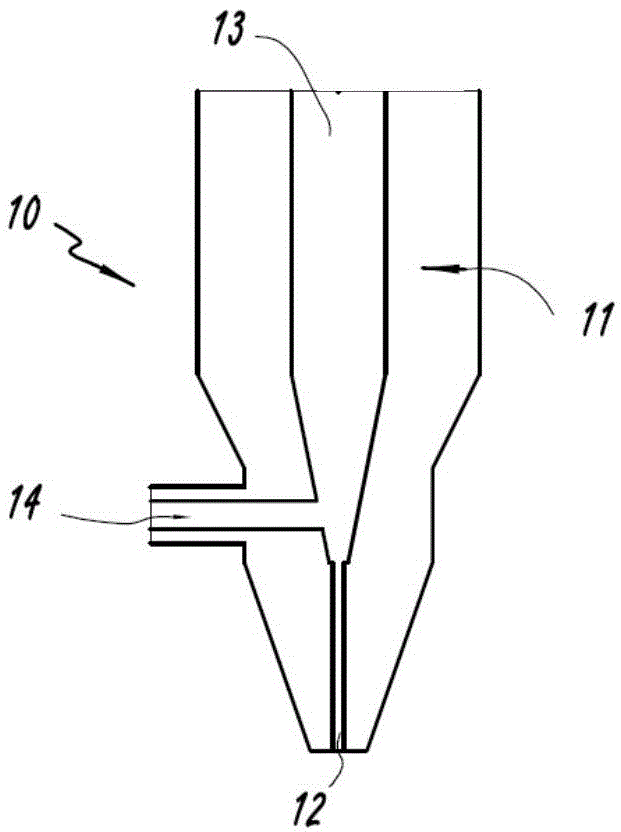

[0069] Such as image 3 As shown, the nozzle 10 of this embodiment includes: a nozzle body 11 , a nozzle inner cavity 13 , a nozzle hole 12 and an injection side pipe 14 . The injection side pipe 14 is positioned at the side of the nozzle inner chamber 13 and communicates with the nozzle inner chamber 13. The second material, which is different from the first material of the printing material, is especially injected with gas, thereby suppressing the problem of lowering printing accuracy caused by the inertia of low-viscosity printing materials. For high-viscosity printing materials, or low-viscosity melt materials printed at relatively low temperatures, the injection side pipe 14 is not necessary, and can be added or deleted as required during the manufacturing process or closed during use.

[0070] Present embodiment processes this nozzle 10 processes as follows:

[0071] (1) adopt the method for stereolithography to process the outer mold 30 of conical nozzle and the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com