Energetic semiconductor bridge and preparation method thereof

A technology of semiconductors and oxides, applied in the field of semiconductor bridges, can solve the problems of difficult preparation of reactive semiconductor bridges, high production costs, complex processes, etc., and achieve the effects of shortening the diffusion and mass transfer distance, convenient equipment, and accelerating the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

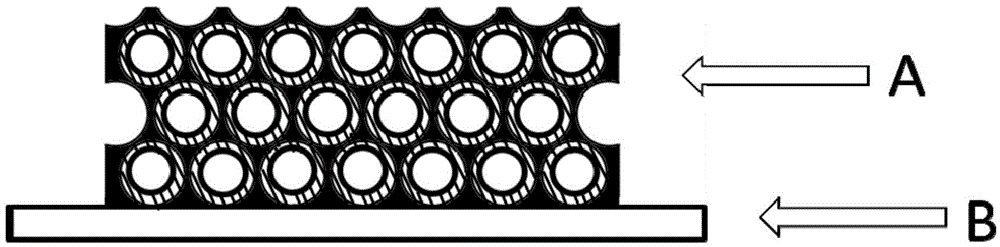

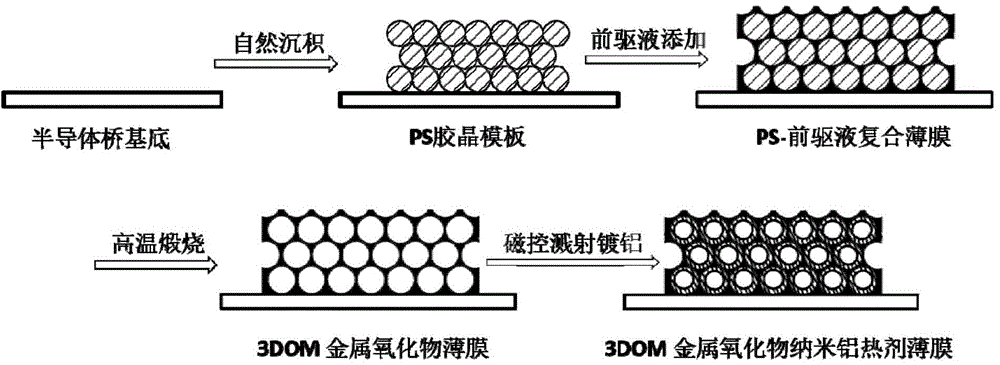

[0039] combine figure 2 , the preparation method of the energetic semiconductor bridge of the present invention comprises the following steps:

[0040] Step 1, preparing PS microspheres, the particle size of the PS microspheres is 200-800nm, dispersed in water to form a PS microsphere emulsion, and the concentration of the PS microsphere emulsion is 2-10wt%;

[0041] Step 2, preparing metal oxide precursor liquid; including the following two metal oxide precursor liquids, respectively as follows:

[0042] (a) the preparation of metal oxide precursor solution, wherein the metal oxide is Mn 2 o 3 , the configuration process of the precursor solution is as follows: Mn(Ac) 2 4H 2 O was added to the mixed solvent of methanol and ethylene glycol and stirred until Mn(Ac) 2 4H 2 O is completely dissolved, and PVP (10000) is added to adjust the viscosity of the precursor solution; the molar ratio of methanol and ethylene glycol is 3:1; Mn(Ac) 2 4H 2 The mass of O added is 0.3-...

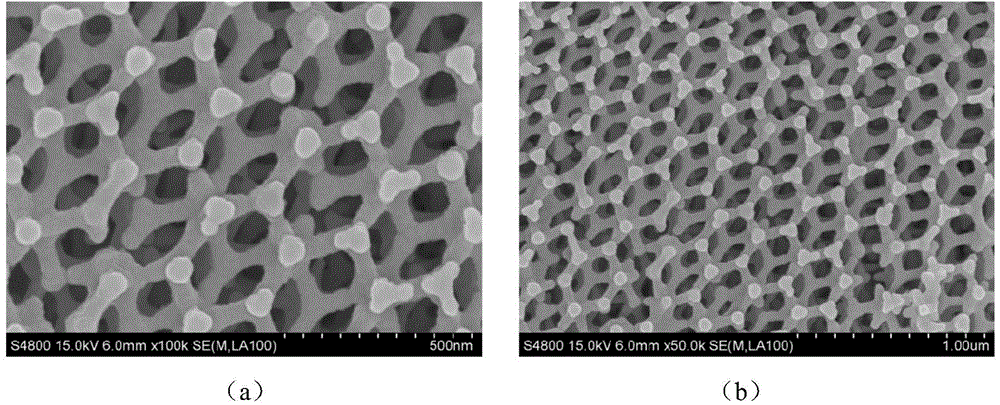

Embodiment 1

[0050] Step 1: Prepare PS microspheres with smooth surface, monodisperse and particle size of 200nm in the laboratory, and disperse them in water to form PS microsphere emulsion with a concentration of 5wt%.

[0051] Step 2: Weigh 7.35g Mn(Ac) 2 4H 2 O was added to 20mL of methanol: ethylene glycol molar ratio was 3:1 mixed solvent and stirred for 2h until Mn(Ac) 2 4H 2 O is completely dissolved for later use. Then weigh 1.0g PVP (10000) and add it to the solution, stir for 12 hours to obtain a certain viscosity of Mn 2 o 3 precursor solution.

[0052] Step 3: Drop 0.05ml of PS microsphere emulsion on the semiconductor bridge substrate, let it dry naturally, then dry it in a vacuum oven at 40°C for 1 hour, and cool it down to room temperature. Three-dimensional long-range ordered PS microsphere colloidal thin films were vertically deposited on semiconductor bridge substrates.

[0053] Step 4: Drop 0.10ml of Mn on the PS microsphere colloidal crystal film obtained in ste...

Embodiment 2

[0061] Step 1: Prepare PS microspheres with smooth surface, monodisperse and particle size of 380nm in the laboratory, and disperse them in water to form PS microsphere emulsion with a concentration of 5wt%.

[0062] Step 2: Weigh 7.35g Mn(Ac) 2 4H 2 O was added to 20mL of methanol: ethylene glycol molar ratio was 3:1 mixed solvent and stirred for 2h until Mn(Ac) 2 4H 2 O is completely dissolved for later use. Then weigh 1.0g PVP (10000) and add it to the solution, stir for 12 hours to obtain a certain viscosity of Mn 2 o 3 precursor solution.

[0063] Step 3: Drop 0.05ml of PS microsphere emulsion on the semiconductor bridge substrate, let it dry naturally, then dry it in a vacuum oven at 40°C for 1 hour, and cool it down to room temperature. Three-dimensional long-range ordered PS microsphere colloidal thin films were vertically deposited on semiconductor bridge substrates.

[0064] Step 4: Drop 0.10ml of Mn on the PS microsphere colloidal crystal film obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com