Carbon-sand filter tank and construction method for anti-corrosive coating of carbon-sand filter tank

The technology of a carbon sand filter and a construction method is applied in the construction field of drinking water treatment equipment, carbon sand filter and its anti-corrosion layer, which can solve problems such as lack of facilities, achieve fast removal speed, good ammonia nitrogen removal effect and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

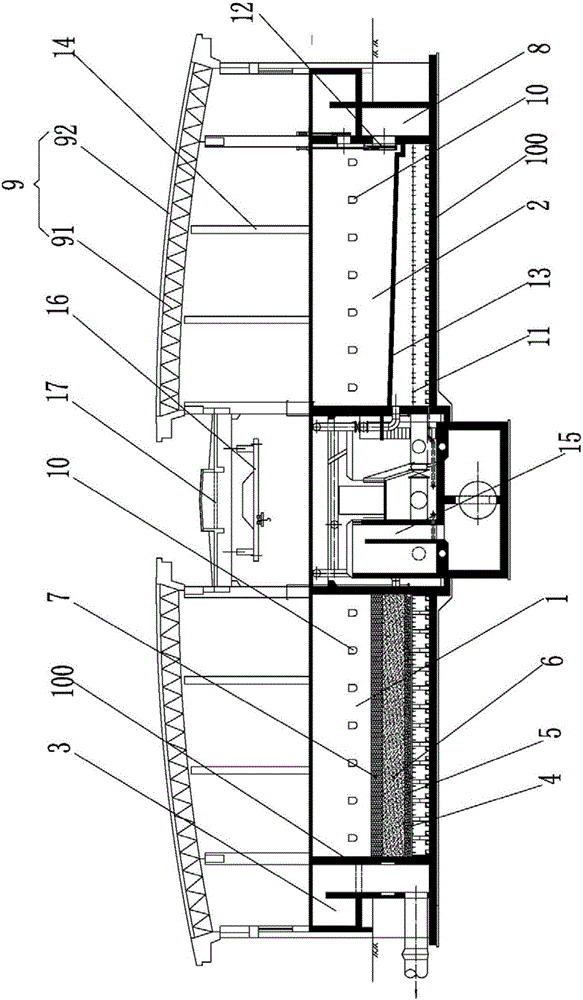

[0033] Please refer to the attached figure 1 Shown, the present invention is a kind of carbon sand filter tank, and it is made of left pool body 1, right pool body 2, water inlet channel 3, filter plate 4, support plate 5, quartz sand layer 6, activated carbon layer 7, water outlet channel 8 And several parts such as roofing 9 form.

[0034] Wherein, the left pool body 1 and the right pool body 2 are arranged side by side and communicated with each other. The inner walls of the left pool body 1 and the right pool body 2 are provided with an anti-corrosion layer 100;

[0035] The upper part of the left pool body 1 and the right pool body 2 is provided with several water distribution tanks 10;

[0036] The filter plate 4, the supporting plate 5, the quartz sand layer 6, and the activated carbon layer 7 are arranged sequentially from the bottom of the left pool body 1 from bottom to top. Due to the rough surface structure of activated carbon 7, it can accommodate a large amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com