Mite-resistant fabric care composite

A technology for fabric care and composition, applied in fiber treatment, textiles and papermaking, etc., which can solve problems such as lack of durable anti-mite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Example 1 ( Preparation example of anti-mite agent )

[0106] The synthetic method of anti-mite agent A adopts the following processing steps:

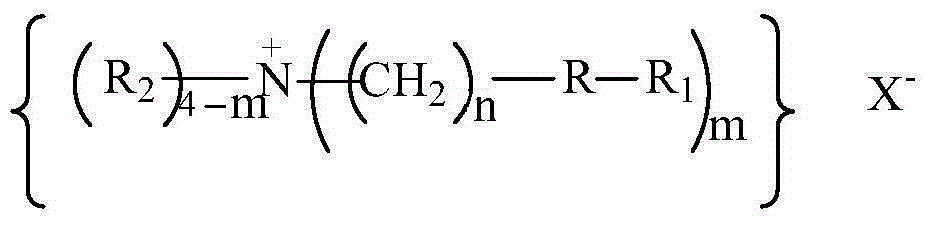

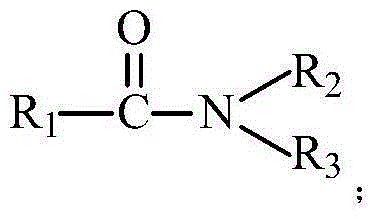

[0107] The anti-mite agent A can be made by amidation reaction, and its synthetic mode is known, and its reaction equation is as follows:

[0108]

[0109] Add 30ml of toluene to a 500mL three-necked flask, then add 3.8g of phenylacetic acid and 7g of diethylamine, start stirring, add 0.1g of phosphorus pentoxide, react for 7 hours, distill the toluene under normal pressure, and then distill under reduced pressure That is, diethylphenylacetic acid amide anti-mite agent is obtained.

Embodiment 2

[0110] Example 2 ( Preparation example of anti-mite agent )

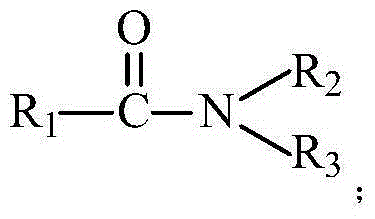

[0111] The synthetic method of anti-mite agent B adopts the following synthetic techniques to obtain:

[0112] The chemical name of anti-mite agent B is N, N-diethyl-m-toluamide, and its synthetic method is well known in the industry. The synthetic method adopted in the present invention is as follows:

[0113]

[0114] In the three-necked flask of 500ml, add 4.1 grams of m-toluic acid, then add 4.5ml of thionyl chloride, add 2 zeolites, one of the three-necked flasks is connected with a condenser tube, and the other is connected with a constant pressure funnel, and the reactant is slowly heated. Until no gas is released, then distill under reduced pressure (85°C / 5mmHg) to remove thionyl chloride in the reactant. Add 30ml of toluene, slowly drop 7 grams of diethylamine in about 20 minutes, start stirring and reflux for 30 minutes, remove the reaction by-products by alkali washing and acid washing, and recover...

Embodiment 1~8

[0125] Embodiment 1~8 (preparation embodiment of anti-mite fabric care composition)

[0126] Table 2 Raw material components and content of preparation examples 1-8 of anti-mite fabric care composition

[0127]

[0128] Wherein TEP-88 is an ester-based quaternary ammonium salt purchased from Solvay; the thickener is purchased from Flosoft FS-222 of Aisen Company. Anti-mite agent A refers to the amide anti-mite agent obtained by embodiment 1; anti-mite agent B refers to the amide anti-mite agent obtained by embodiment 2.

[0129] The preparation process of the anti-mite fabric care composition preparation examples 1-8 of the present invention is as follows:

[0130] (1) Add deionized water in proportion, start stirring, and raise the temperature to 50°C;

[0131] (2) Heat TEP-88 to 50°C, keep it in a liquid state, then slowly add it to water, and stir for 10 minutes;

[0132] (3) When the temperature of the ingredients drops to 45°C, add thickeners, essences, preservati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com