Cooling Control Method of Steam Turbine Shutdown

A technology of shutdown cooling and control method, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of difficult standardization control, affecting the life of the unit, cylinder deformation, etc., to improve reliability and economy, shorten disk Vehicle cooling time, the effect of realizing standardized control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

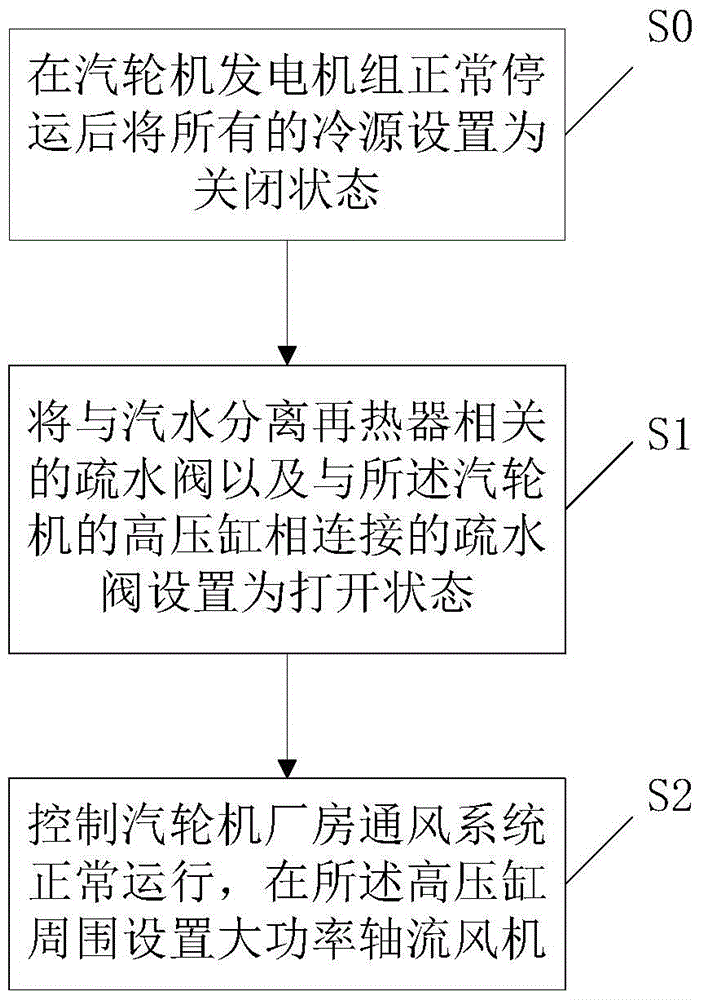

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

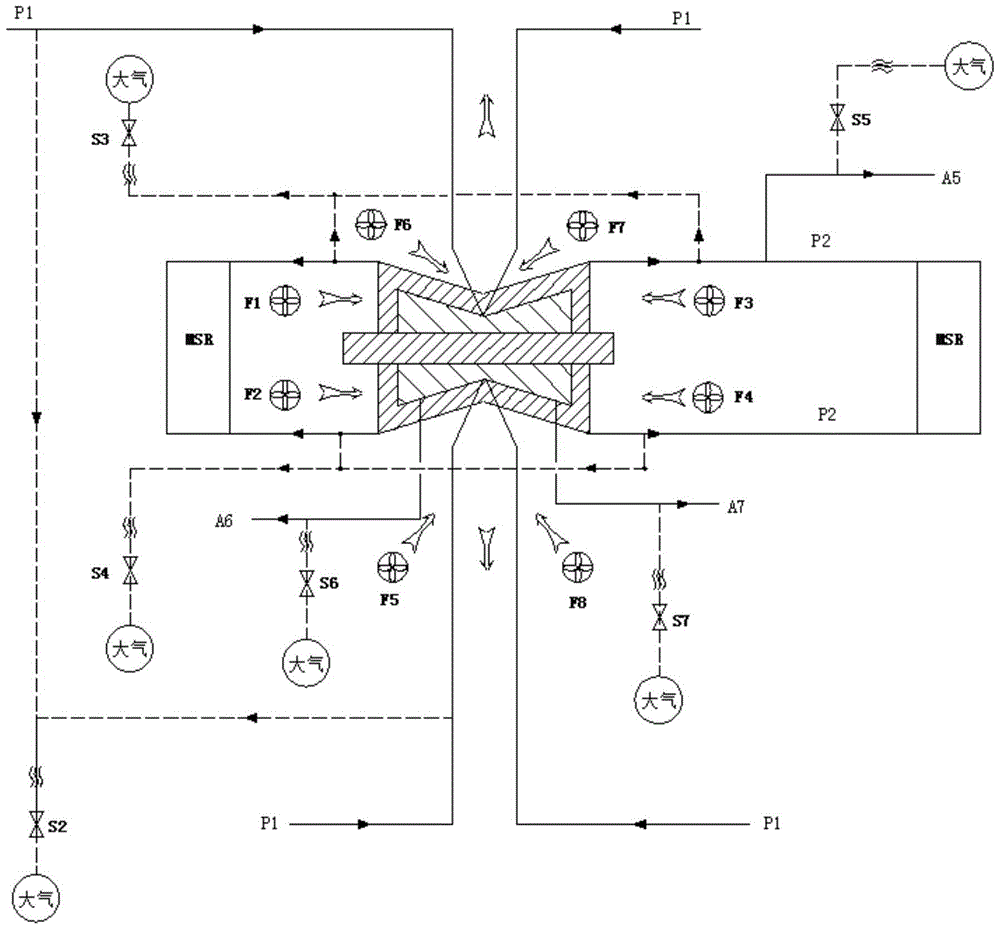

[0038] refer to figure 1 , is a schematic diagram of the natural convection cooling of the steam turbine at shutdown;

[0039] The steam turbine includes a high-pressure rotor and a high-pressure cylinder, the high-pressure cylinder is connected with the steam-water separation reheater MSR, and the high-pressure cylinder specifically includes an inner cylinder and an outer cylinder. The pipelines connected to the high-pressure cylinder include steam extraction pipelines, high-pressure steam inlet pipelines P1, and high-pressure steam exhaust pipelines P2. The dotted lines in the figure represent the drain pipelines in the pipelines; wherein, the steam extraction pipelines specifically include A5 steam extraction pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com