Hydrophilic treatment method of reverse osmosis membrane

A technology of reverse osmosis membrane and treatment method, applied in the field of hydrophilization treatment agent, which can solve the problems of peeling, loss of hydrophilization effect, and decrease of RO membrane flux, and achieve the effect of easy modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

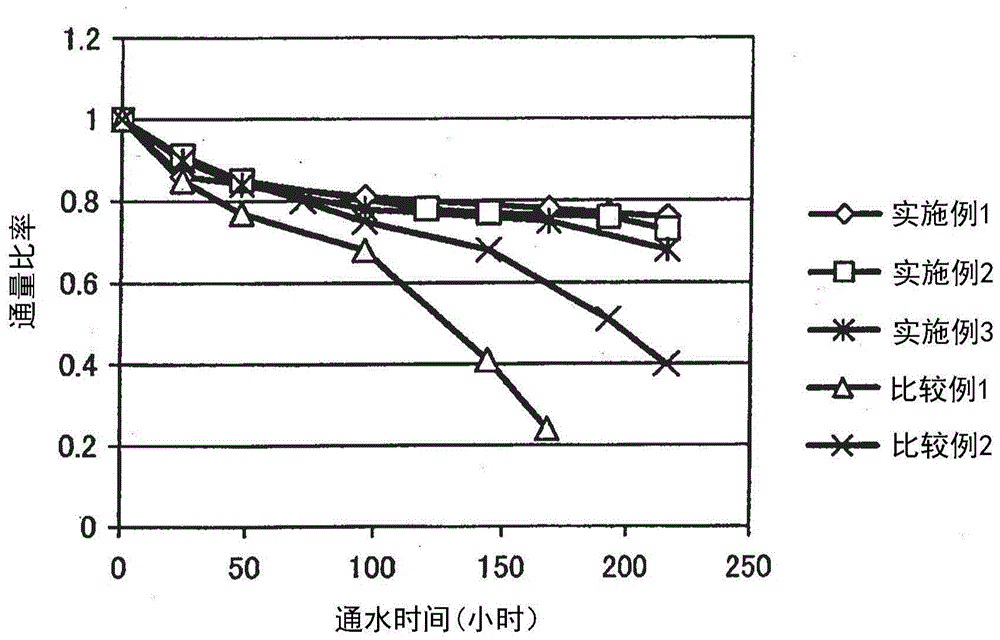

[0057] The Nitto Denko RO membrane "ES20" (flat membrane, diameter 32 mmφ) was subjected to a hydrophilic treatment under the following conditions. Modified polyvinyl alcohol having a polyalkylene oxide chain, which is a hydrophilizing agent, was used by dissolving in ultrapure water (60°C). After the hydrophilization treatment, the biologically treated water from the drainage recovery device of the Kurita Industrial Co., Ltd. Development Center was used to conduct a water flow test to verify the flux stability.

[0058] 〈Hydrophilic treatment〉

[0059] Hydrophilic treatment agent: "ECOMATY WO-320N" manufactured by Nippon Synthetic Chemical Industry Co., Ltd. (modified polyvinyl alcohol having a polyethylene oxide chain, saponification degree of 98.5% or more)

[0060] Concentration: 100mg / L

[0061] Water time: 5 hours

[0062] Inlet pressure: 0.75MPa

[0063] Flux: 1.0m / day

[0064] Water temperature: 25°C

[0065] 〈Water penetration test〉

[0066] Water flow evaluati...

Embodiment 2

[0072] Except using "ECOMATY WO-320R" (modified polyvinyl alcohol having a polyethylene oxide chain, saponification degree 86.5-89.5%) manufactured by Nippon Synthetic Chemical Industry Co., Ltd., the same test as in Example 1 was carried out. Quantitative stability. The results are shown in figure 1 .

Embodiment 3

[0074] Except that the inlet pressure during the hydrophilization treatment was set to 0.2 MPa, the same test as in Example 1 was carried out to examine flux stability. The results are shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com