Raw material for all-ceramic dental restoration system and rapid prototyping method of raw material

A technology of oral restorative and raw materials, applied in dental preparations, dental prostheses, pharmaceutical formulations, etc., can solve problems such as large porosity, low solid content of ceramic raw materials, cracking, etc., and achieve high strength and fewer defects in ceramic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

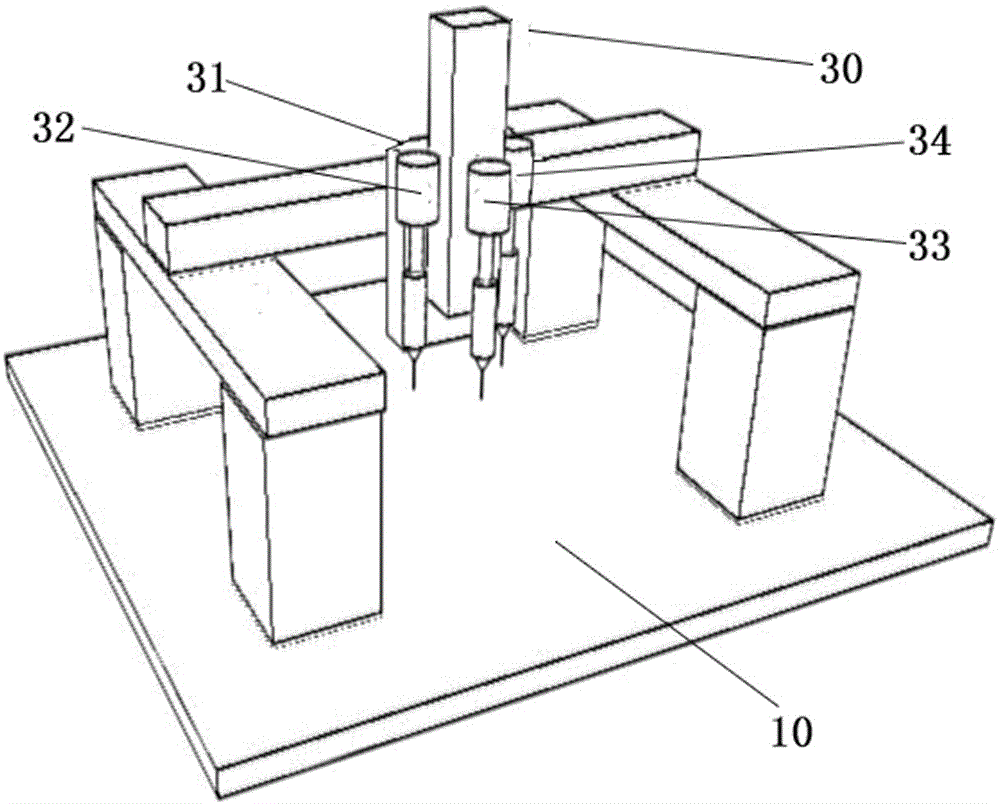

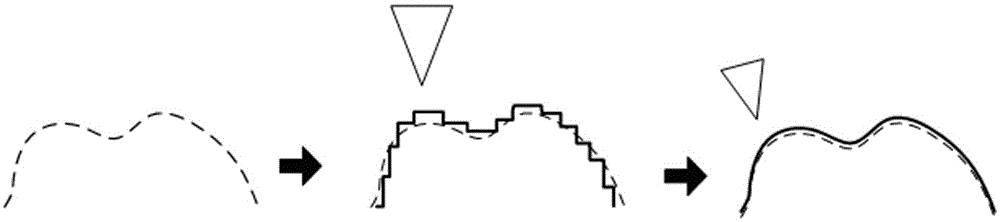

Method used

Image

Examples

Embodiment 1

[0041] Take 50g of zirconia ultrafine powder (average particle size 1 micron), add it to 50g of sodium alginate (anionic water-soluble polymer) solution containing 2% by weight, disperse vigorously with an ultrasonic pulverizer for 10 minutes to form a colloid, and then add A small amount of 10% hydrochloric acid was used to adjust the pH to 5 to make the colloid gel, and then homogenized 3 times with a three-roll mill to finally obtain a rapid prototyping raw material with a solid content of 50%. After the raw material is rapidly formed into an embryo body, it is put into a microwave oven and dried and sintered at a temperature of 1600 degrees Celsius for 10 minutes to obtain a finished product.

Embodiment 2

[0043] Take 45g of zirconia ultrafine powder and 5g of alumina ultrafine powder (average particle size 1 micron), add it to 50g of sodium alginate (anionic water-soluble polymer) solution containing 2% by weight, and disperse vigorously with an ultrasonic pulverizer Form a colloid in 10 minutes, then add a small amount of 10% hydrochloric acid to adjust the pH to 5 to gel the colloid, homogenize it with a three-roll mill for 3 times, and finally obtain a rapid prototyping raw material with a solid content of 50%. After the raw material is used for rapid molding into an embryo body, it is first treated with cold isostatic pressing for 10 minutes, and then put into a microwave oven for drying and sintering at a temperature of 1600 degrees Celsius for 10 minutes to obtain a finished product.

Embodiment 3

[0045] Ultrafine ceramic powder 75g, colorant 5g, fluorescer 5g, dispersant 5g, coagulant 20g, thickener 5g, flow aid 5g, strengthening aid 10g, the average particle size of described ultrafine ceramic powder is 10 microns , to prepare raw materials. The rest are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com