Preparation method for water-soluble copper sulphide quantum dots

A copper sulfide, quantum dot technology, applied in copper sulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of quantum dot instability, limited application, easy agglomeration, etc. Simple and controllable, inhibiting the activity of cancer cells, and the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Add 1.550g copper chloride to 150mL absolute ethanol, stir until completely dissolved, add 1.602g thioacetamide to 200mL absolute ethanol, stir until completely dissolved, slowly add copper chloride solution to thioethyl In the amide solution, ultrasonication for 10 minutes forms the precursor;

[0013] (2) Take 300mL of pre-refrigerated precursor, add 300mL of pre-refrigerated high-purity water under stirring conditions, react the mixture of the two at 4°C for 24h, centrifuge at a centrifugal rate of 13000r / min after the reaction, and centrifuge the obtained product Alternately washing with absolute ethanol and high-purity water three times, and drying to obtain water-soluble copper sulfide quantum dots.

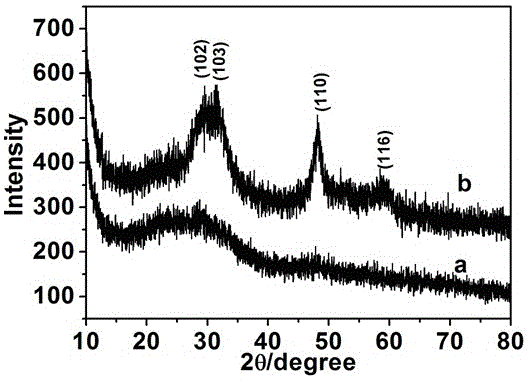

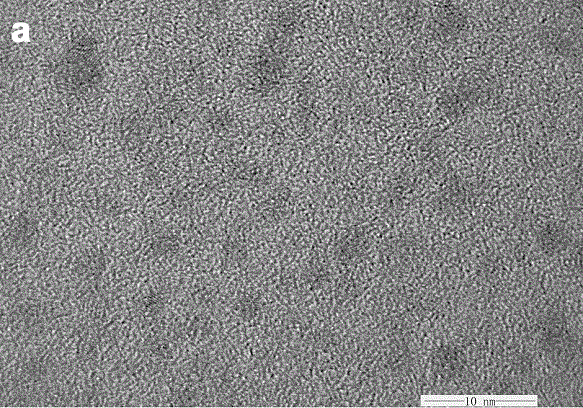

[0014] figure 1 a is the XRD spectrum of the product, as can be seen from the figure, there is no obvious peak, indicating that the product obtained under this condition is an amorphous copper sulfide quantum dot, figure 2 a is the transmission electron micros...

Embodiment 2

[0016] (1) Add 1.550g copper chloride to 150mL absolute ethanol, stir until completely dissolved, add 1.602g thioacetamide to 200mL absolute ethanol, stir until completely dissolved, slowly add copper chloride solution to thioethyl In the amide solution, ultrasonication for 10 minutes forms the precursor;

[0017] (2) Take 300mL of precursor, add 300mL of high-purity water under stirring conditions, react the mixture of the two at 40°C for 0.5h, centrifuge at a centrifugal rate of 13000r / min after the reaction, and centrifuge the obtained product with absolute ethanol and High-purity water was alternately washed three times, and water-soluble copper sulfide quantum dots were obtained after drying.

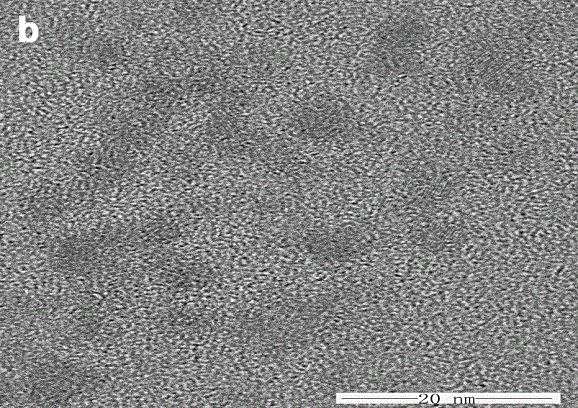

[0018] figure 1 b is the XRD spectrum of the product, which is completely consistent with the standard spectrum (JCPDS NO.65-3928) of the hexagonal CuS crystal of indigosite, and its lattice parameters a=0.3768nm, c=1.6270nm, compared with the standard spectrum , the diffraction ...

Embodiment 3

[0020] (1) Add 1.550g copper chloride to 150mL absolute ethanol, stir until completely dissolved, add 1.602g thioacetamide to 200mL absolute ethanol, stir until completely dissolved, slowly add copper chloride solution to thioethyl In the amide solution, stir for 10 minutes to form a precursor;

[0021] (2) Take 300mL of the precursor, add 300mL of high-purity water under stirring conditions, and react the mixture of the two at 80°C for 0.5h. High-purity water was alternately washed three times, and water-soluble copper sulfide quantum dots were obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com