Scale removing agent and preparation method thereof

A technology of descaling agent and metal corrosion inhibitor, which is applied in the fields of descaling and water softening, chemical instruments and methods, complex/solubilizing agent treatment, etc. It can solve the problems of shortened service life, corrosion of equipment or containers, cumbersome procedures, etc. , to achieve energy saving, thorough descaling and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

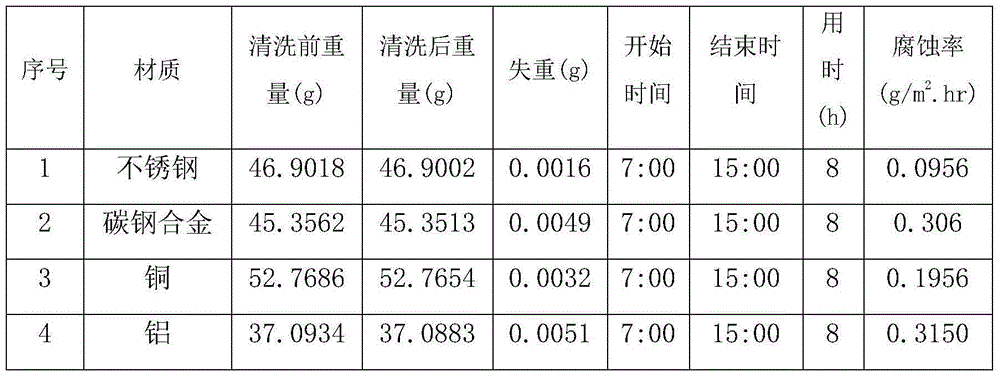

Examples

preparation example Construction

[0043] The preparation method of descaling agent of the present invention comprises the steps:

[0044] (1) Add the solid material fumaric acid, citric acid, amino sulfuric acid, maleic acid, and sodium dodecylbenzenesulfate into the chemical reactor successively, and then add an appropriate amount of water to stir and dissolve the solid material;

[0045] (2) Add the liquid materials lactic acid, hydrochloric acid and corrosion inhibitor in turn into the chemical reactor and stir to make them fully dissolved;

[0046] (3) After filtering the homogeneously mixed materials, a descaling agent is obtained.

[0047] Wherein, the speed when stirring in step (1) is 200-300r / min.

[0048] Wherein, the speed when stirring in step (2) is 1500r / min.

[0049] Wherein, what adopt when filtering in step (3) is stainless steel strainer.

[0050] Wherein, the filter screen mesh number that adopts in step (3) is 150-230 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com