Method for preparing porous hydrogel through micropore self foaming

A porous hydrogel and self-foaming technology is applied in the field of preparation of hydrogel materials, which can solve the problems of prolonging the preparation time of materials, easily destroying the network structure of hydrogels, prolonging the preparation period of materials, etc., and achieving a good biological phase. Capacitance, simple process flow, the effect of shortening the time of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

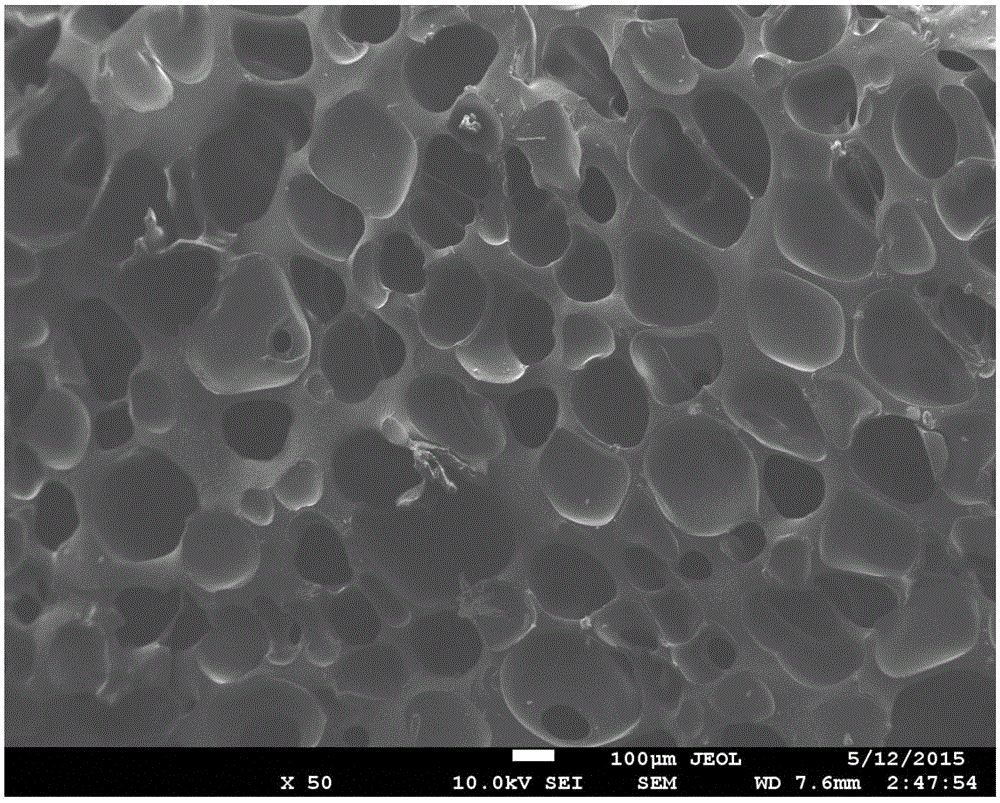

Image

Examples

Embodiment 1

[0022] A method for preparing porous hydrogel by microporous self-foaming, the steps are as follows:

[0023] A, at room temperature, 4 parts of weight of polyglutamic acid and 2 parts of weight of lysine are dissolved in 45 parts of weight of distilled water, stirred evenly at a speed of 100r / min, to obtain polyglutamic acid and lysine homogeneous solution;

[0024] B. In the homogeneous solution obtained in step A, add 3 parts by weight of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 2 parts by weight of N-hydroxysuccinyl Imine, stir rapidly at a speed of 500r / min to form a homogeneous solution to be foamed;

[0025] C. Pour the homogeneous solution to be foamed obtained in step B into the mold for preparing the hydrogel, let it stand, and start foaming to form a hydrogel;

[0026] D. Soak and wash the hydrogel obtained in step C with alcohol to remove unreacted 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide , that com...

Embodiment 2

[0029] A method for preparing porous hydrogel by microporous self-foaming, the steps are as follows:

[0030] A, at room temperature the polyglutamic acid of 7 parts weights and the lysine of 5 parts weights are dissolved in the distilled water of 55 parts weights, stir with the rotating speed of 200r / min, obtain polyglutamic acid and lysine homogeneous solution;

[0031] B. In the homogeneous solution obtained in step A, add 3 to 7 parts by weight of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 4 parts by weight of N-hydroxyl For succinimide, stir rapidly at a speed of 800r / min to form a homogeneous solution to be foamed;

[0032] C. Pour the homogeneous solution to be foamed obtained in step B into the mold for preparing the hydrogel, let it stand, and start foaming to form a hydrogel;

[0033] D. Soak and wash the hydrogel obtained in step C with alcohol to remove unreacted 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimid...

Embodiment 3

[0035] A method for preparing porous hydrogel by microporous self-foaming, the steps are as follows:

[0036] A, at room temperature, 5 parts of weight of polyglutamic acid and 3 parts of weight of lysine are dissolved in 50 parts of weight of distilled water, stirred evenly at a speed of 150r / min, to obtain polyglutamic acid and lysine homogeneous solution;

[0037] B, in the homogeneous solution obtained in step A, add 4 parts of weight of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 3 parts of weight of N-hydroxysuccinyl Imine, stir rapidly at a speed of 600r / min to form a homogeneous solution to be foamed;

[0038] C. Pour the homogeneous solution to be foamed obtained in step B into the mold for preparing the hydrogel, let it stand, and start foaming to form a hydrogel;

[0039] D. Soak and wash the hydrogel obtained in step C with alcohol to remove unreacted 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide , that com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com