Culturing method of Lb.plantarum capable of highly producing gamma-aminobutyric acid (GABA) and application

A technology of plantaractobacillus and cultivation method, which is applied in the field of cultivation of high-yielding γ-aminobutyric acid plantaractobacillus, can solve the problems of limited metabolic capacity of strains and unreasonable cultivation methods, and achieve short cultivation time and high production of γ-aminobutyric acid. The effect of high yield and low inoculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Identification, preservation and activation of the bacterial classification of embodiment 1

[0037] 1. Identification and preservation of strains

[0038] In order to determine the purity and species of the purchased strains, add an appropriate amount of liquid MRS to the purchased freeze-dried bacterial powder for culture, mix evenly, spread the appropriately diluted bacterial liquid on the solid MRS medium, and cultivate at 30°C until a single colony is formed . Pick 5 single colonies at random, inoculate them in 4 mL of liquid MRS medium, and culture them purely at 30°C for 12 hours until they reach the logarithmic growth phase, and store them at 4°C for later use.

[0039] Gram-stained five single-colony liquids were magnified at 1000 times, and examined under a microscope. At the same time, re-inoculate the pure culture bacteria solution into the corresponding MRS medium according to the ratio of 2%, culture at constant temperature to reach the logarithmic growt...

Embodiment 2

[0045] The optimization of embodiment 2 culture conditions

[0046] 1. Optimization of initial pH of fermentation

[0047] The specific operation is as follows:

[0048] 1) Prepare MRS medium with pH values of 4.0, 4.2, 4.5, 5.0, 5.8, 6.0, and 6.8, respectively, pack them in 200mL Erlenmeyer flasks, sterilize under high temperature and high pressure, and store them at 4°C for later use. Three parallels were set for each pH condition;

[0049] 2) After activating the strain according to the method in 2.3.1, inoculate 200mL of PLP containing 100mM L-MSG and 20μM according to 3%, and let it stand for anaerobic fermentation at 37°C for 24h;

[0050] 3) The fermentation broth was centrifuged at 12,000 rpm for 10 min at 4°C, and the supernatant was taken and kept at 4°C for later use, and the content of γ-aminobutyric acid in it was detected by high performance liquid chromatography.

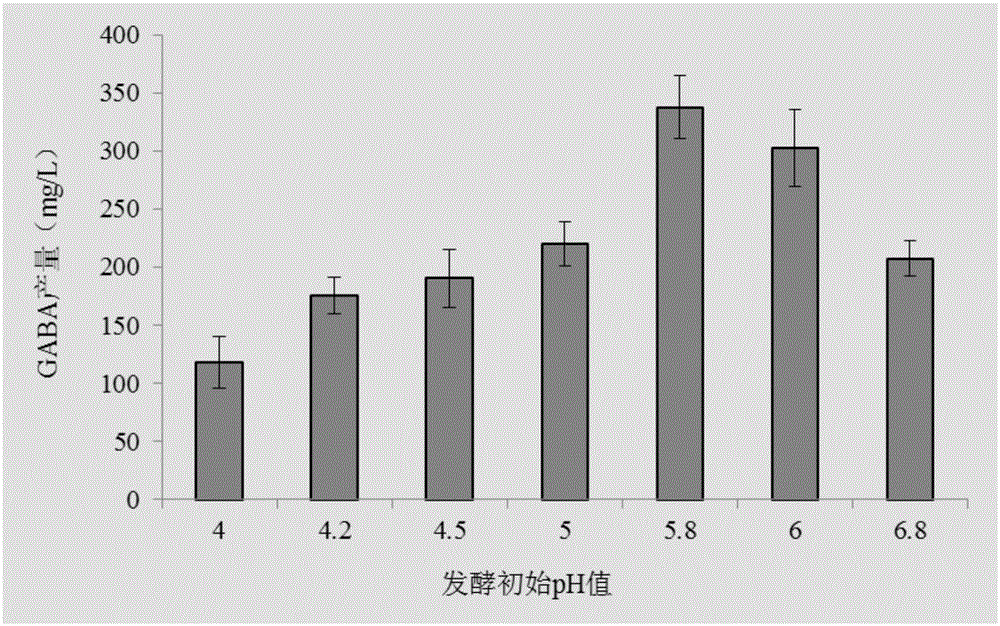

[0051] The measured results are as figure 1 shown. from figure 1 It can be seen that the ini...

Embodiment 3

[0078] The determination of embodiment 3 fermentation time

[0079] The frozen strains were streaked in three areas on the MRS solid medium plate to obtain a single colony, and the single colony was picked and cultured in 4 mL of MRS liquid medium at 30°C for 12 hours, and the seeds obtained after continuous expansion for two generations were used for fermentation. The fermentation medium was MRS medium, the fermentation system was 2L, the initial pH value of the fermentation was 5.5, the fermentation temperature was 37°C, and the fermentation time was 72h. In the induction group, 100 mM L-MSG was additionally added, and in the control group, except that L-MSG was not added, other fermentation conditions were the same as those of the induction group. Experimental results such as Image 6 shown.

[0080] from Image 6 It can be seen that in the initial stage of fermentation, the difference in γ-aminobutyric acid content in the fermentation broth between the experimental grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com