Automatic quantitative sampling device

A quantitative sampling and sampling system technology, applied in the direction of sampling devices, etc., can solve the problems of high cost, cumbersome operation, and sample cross-contamination of electric pipettes, and achieve long-term stable operation, accurate volume control, and short sampling pipelines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

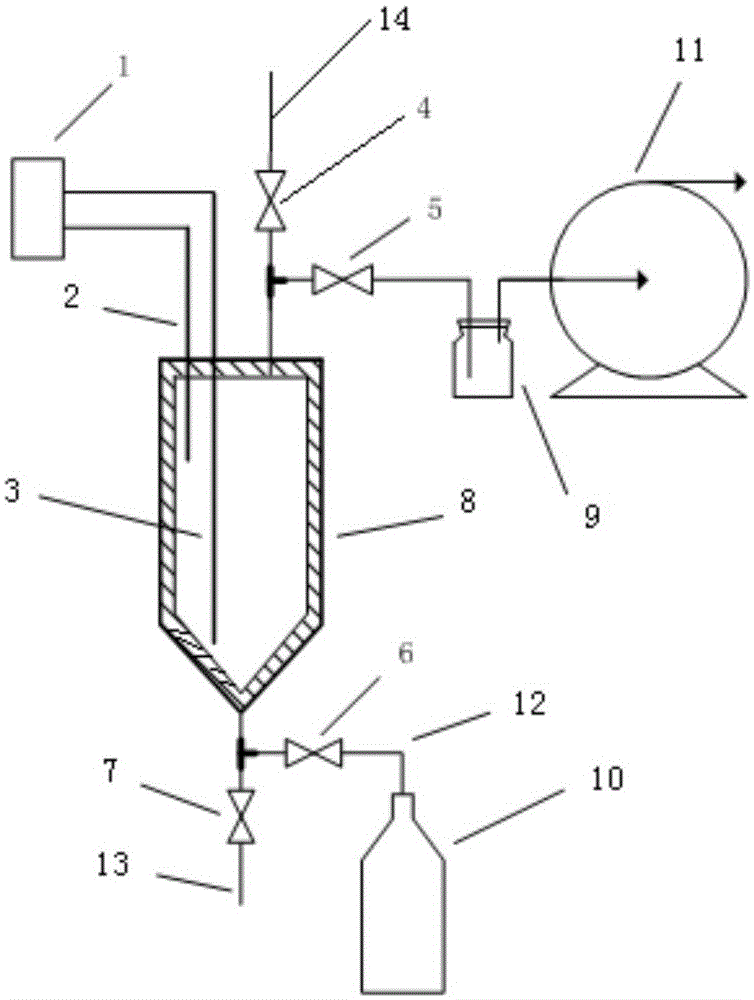

[0029] An automatic quantitative sampling device, such as figure 1 As shown, the device is used in the technical field of radioactive sample sampling. The device mainly includes a conductivity liquid level control system and a sampling system, wherein the sampling system includes a vacuum pump, a buffer bottle and a graduated container, and the vacuum pump is sequentially connected with the buffer bottle and the graduated container. System negative pressure;

[0030] The conductance liquid level control system includes a signal controller 1, a first electrode 2 and a second electrode 3, one end of the first electrode 2 and the second electrode 3 is connected to the signal controller 1, and the other end is located in the scale container 8; the scale The container 8 is sealed with the first electrode 2 and the second electrode 3 with ferrule.

[0031] The upper end of the scale container 8 is provided with an emptying pipe 14, and the bottom is provided with a liquid inlet pip...

Embodiment 2

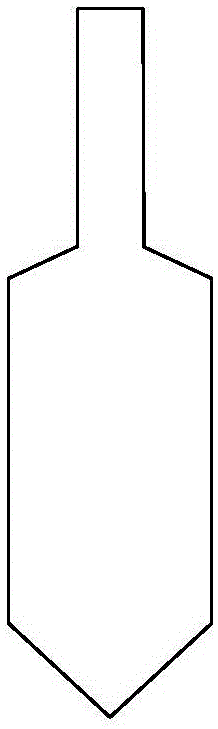

[0042] Different from embodiment 1, the shape of the graduated container is as figure 2 As shown, the bottom is an inverted cone, and the middle and upper parts are cylinders, wherein the diameter of the upper cylinder is smaller than that of the middle cylinder.

Embodiment 3

[0044] Different from Embodiment 1, the material of the first electrode 2 and the second electrode 3 is stainless steel. The material of the scale container 8 is glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com