Preparing method for styrene-acrylic resin/polyester resin compound type static charge image color matching agent

A technology of electrostatic charge image and polyester resin, applied in developer, electrography, optics, etc., can solve the problems of uneven dispersion of wax, damage to low-temperature fixing performance, and increase of polyester units, etc. The method is simple, reliable, and excellent Offset resistance, high image quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of colorant dispersion: 60g carbon black (Cabot company) and 30g dodecyltrimethylammonium chloride and 410g water are stirred and pre-dispersed at room temperature, and then this dispersion is added to the high-speed dispersant for dispersion , By dispersing for 2h, the colorant dispersion liquid was obtained, and its particle size was 120nm.

[0031] Preparation of colorant-containing styrene-acrylic polymer composite emulsion: 75g dodecyltrimethylammonium chloride is dissolved in 1650g water, then it is added in the reactor, 440g of the above-mentioned colorant dispersion is dropped into the reactor, and the temperature is raised to 75°C, add 800g of potassium persulfate aqueous solution (containing 20g of potassium persulfate) to the reaction kettle, then gradually mix 1400g of styrene, 300g of butyl acrylate, 40g of methacrylic acid and 13g of dodecyl mercaptan within 2h. Add it into the reaction kettle, raise the temperature of the system to 80°C after ...

preparation example

[0035] Preparation of wax dispersion: 60g of wax (behenyl behenate), 28g of sodium lauryl sulfate and 130g of water were stirred and dissolved at 90°C, and then the mixture was quickly added to the high-speed dispersant for Dispersion, after 2 hours of dispersion, a milky white wax dispersion liquid with a particle size of 130nm was obtained. The particle size is measured by a Beckman Coulter LS230.

[0036] Dissolve 20g of sodium lauryl sulfate and 2g of decyl alcohol polyoxyethylene ether in 300g of water, then 75g of the above wax dispersion, 180g of acrylic modified bisphenol A epoxy vinyl ester (brand DERAKANE 411), 45g Butyl acrylate and 7.5g of dodecyl mercaptan mixture are added to the reactor, stirred at room temperature to prepare the emulsion prepolymer, the reactor is warmed up to 75°C, and then 150g of potassium persulfate aqueous solution is added in the reactor (the content of potassium persulfate 3g), then the temperature was raised to 80°C, and the temperatur...

preparation example 1

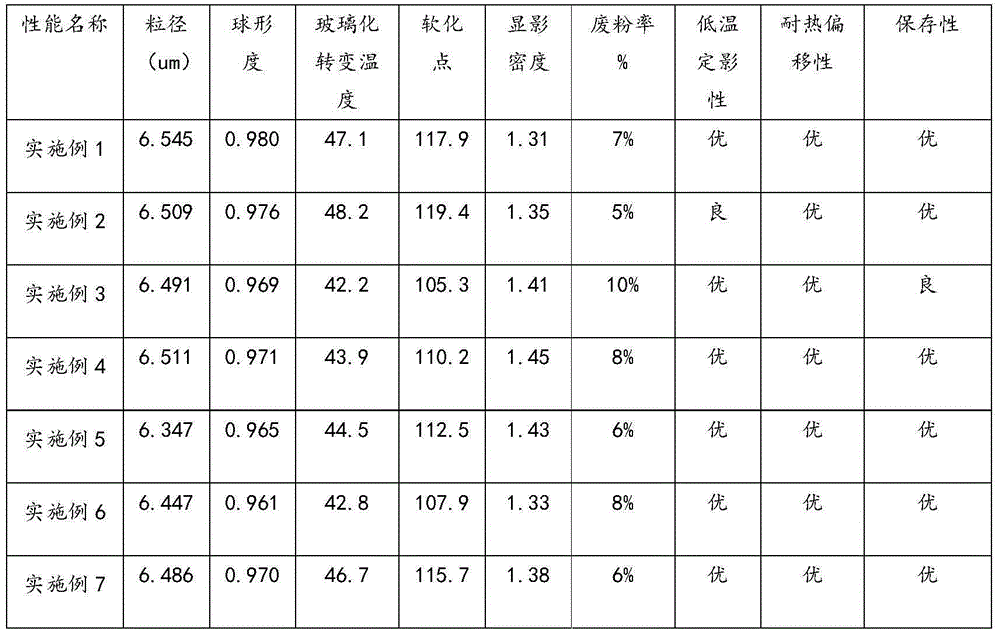

[0046] 100g of emulsion A1 is added in the reactor, the speed of adjusting stirring is 500rpm, then emulsion B1 is gradually added in the reactor within 20 minutes under stirring, then 60g of 1% polyaluminum chloride is added in the reactor, Adjust the pH of the system to 3, start to heat up after stirring for 30 minutes, raise the temperature of the system to 65°C after 30 minutes, then reduce the stirring speed of the system to 200rpm, and then start to detect the change of the particle size of the system, when the particle size of the aggregated particles When increasing to 7 μm, add nonionic surfactant X-405 (Dow Chemical) to the system, then increase the stirring speed to 350rpm, then raise the temperature to 95°C for spherification, when the sphericity of the particles reaches 0.96 (using FPIA-3000 measurement) above, cool, use a centrifuge to filter, wash with water, heat and dry under reduced pressure, and the final particle size is about 6.5um. The toner is obtained b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com